Meat stuffing formula for crisp sausages, automatic processing equipment and processing method thereof

An automatic sausage processing and sausage technology, which is applied to the equipment for ligating sausage casings, processed meat, and sausage production, etc., which can solve the problems of tediousness, slow labor efficiency, and singleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A meat filling formula for crispy sausages, characterized in that it consists of the following components in parts by weight:

[0050] Main ingredients: 36 parts of hind leg muscle, 51 parts of minced meat;

[0051] Accessories: 6.5 parts of sugar, 4 parts of ice water, 1 part of sausage seasoning powder, 1.4 parts of sorghum wine, 0.8 parts of edible salt, 0.6 parts of high fresh essence; 0.09 parts of white pepper powder, 0.04 parts of sodium erythorbate, 0.025 parts of ethyl maltol, and 0.003 parts of sodium nitrite.

Embodiment 2

[0053] A meat filling formula for crispy sausages, characterized in that it consists of the following components in parts by weight:

[0054] Main ingredients: 35.46 parts of hind leg muscle, 51.42 parts of minced meat;

[0055] Accessories: 6.03 parts of white sugar, 4.43 parts of ice water, 1.51 parts of sausage seasoning powder, 1.02 parts of sorghum wine, 1.00 parts of edible salt, 0.355 parts of high fresh essence; 0.071 parts of white pepper powder, 0.053 parts of sodium erythorbate, 0.022 parts of ethyl maltol, and 0.005 parts of sodium nitrite.

[0056] This embodiment is the best embodiment.

Embodiment 3

[0058] A meat filling formula for crispy sausages, characterized in that it consists of the following components in parts by weight:

[0059] Main ingredients: 35 parts of hind leg muscle, 52 parts of minced meat;

[0060] Accessories: 5.5 parts of sugar, 5 parts of ice water, 2 parts of sausage seasoning powder, 0.6 parts of sorghum wine, 1.2 parts of edible salt, 0.1 part of high fresh essence; 0.05 parts of white pepper powder, 0.06 parts of sodium erythorbate, 0.02 parts of ethyl maltol, and 0.007 parts of sodium nitrite.

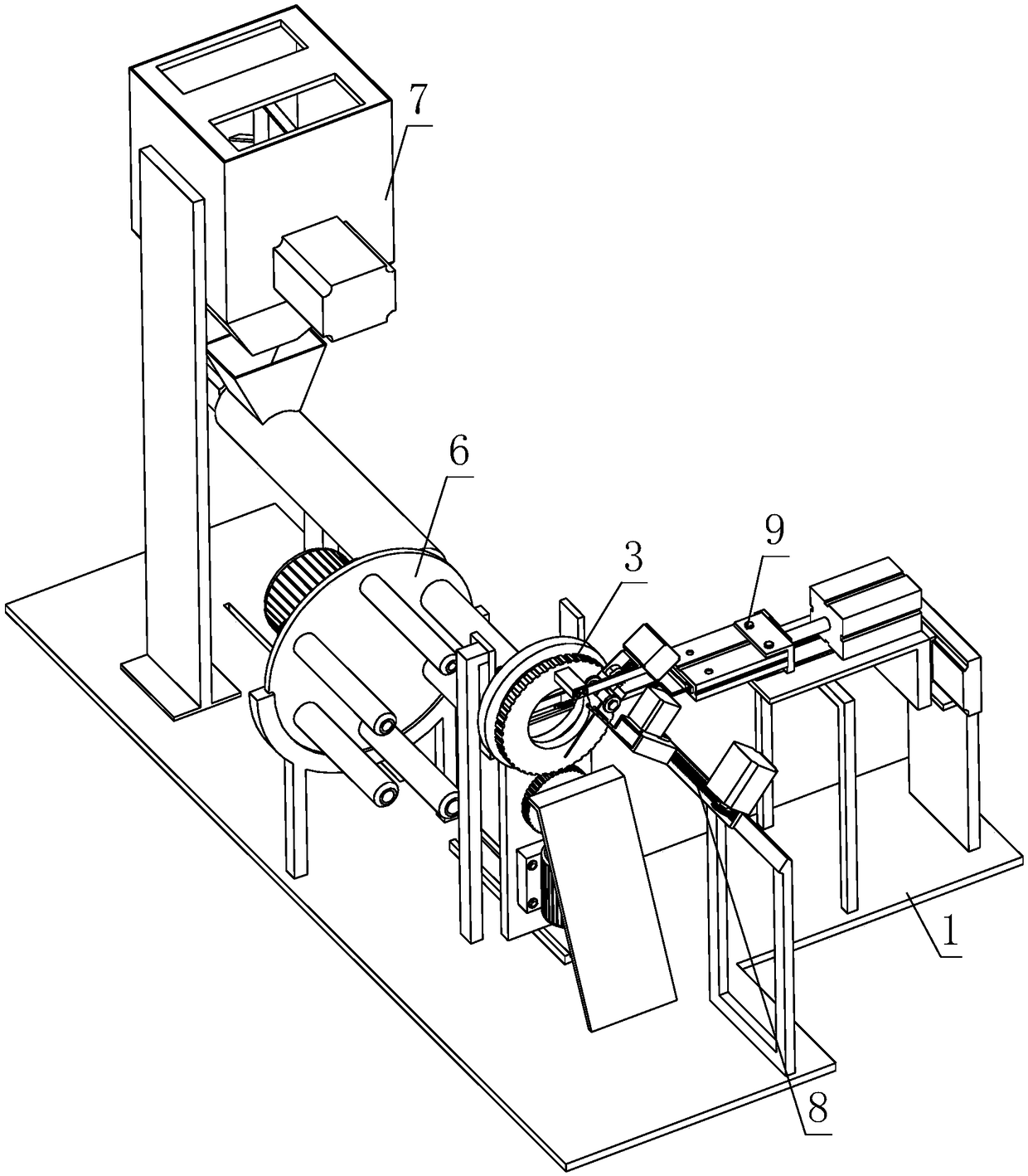

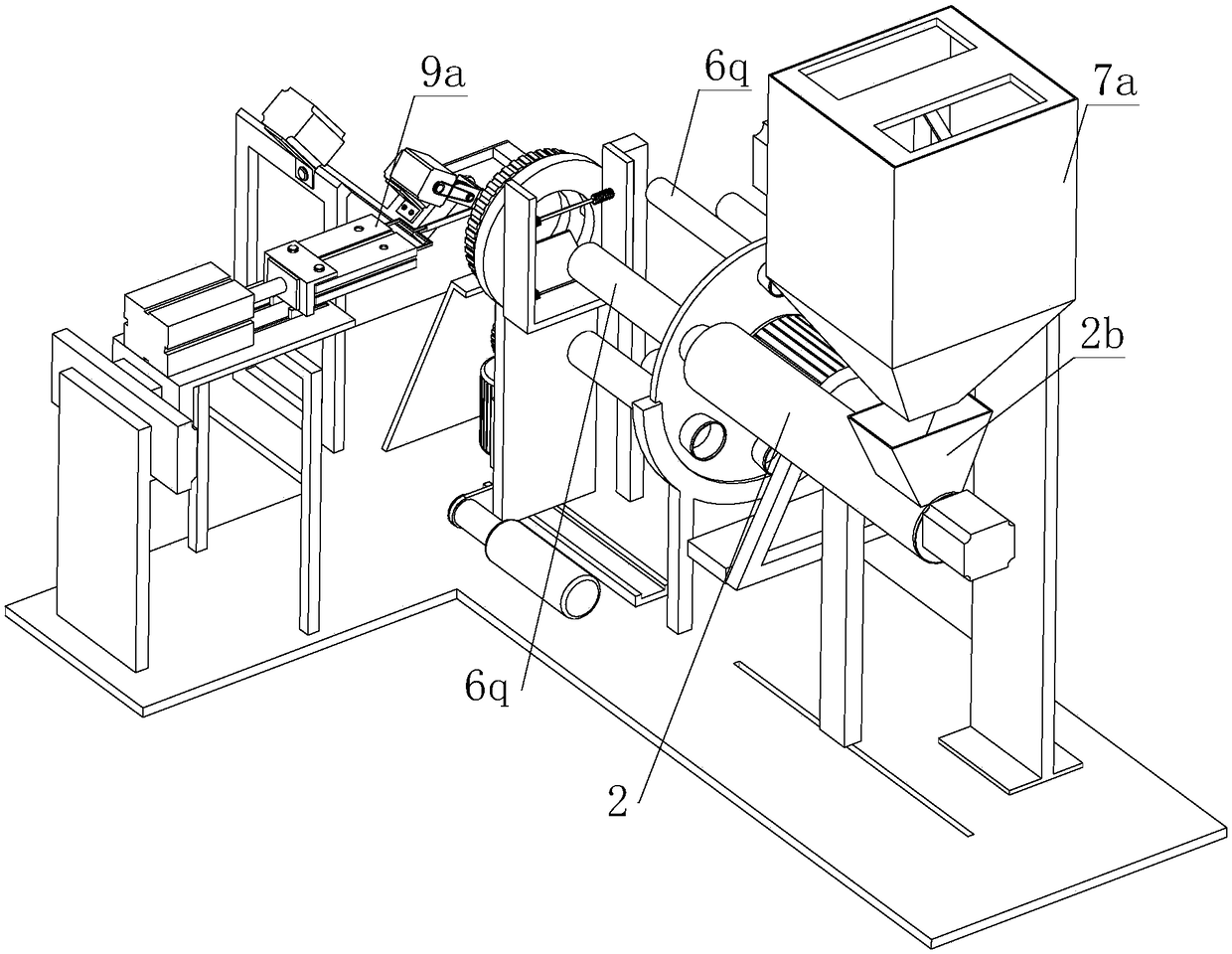

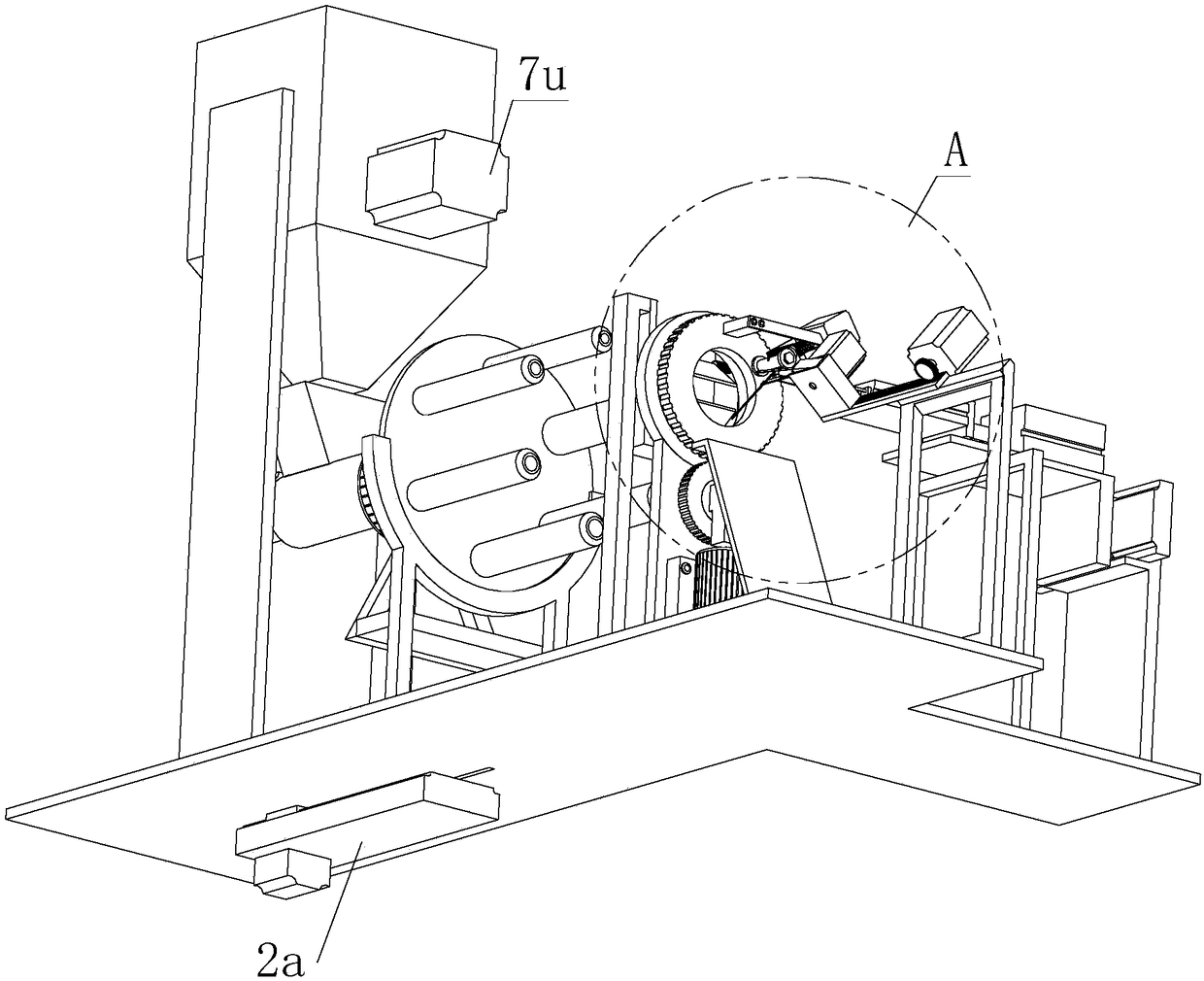

[0061] refer to Figure 1 to Figure 9 The shown automatic processing equipment for crispy sausages includes a processing table 1, a stirring device 7, a screw feeder 2, a bowel diameter switching device 6, a binding device 3, a cam shearing device 8, a traction device 9, and a screw feeder 2 The horizontally moving electric cylinder 2a is installed on the top of the processing table 1, the bowel diameter switching device 6 is installed at the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com