A decoupling mechanism and test device for two-axis synchronous vibration test

A synchronous vibration and decoupling technology, used in vibration testing, measuring devices, and testing of machine/structural components, etc., can solve the problems of poor safety and reliability of synchronous vibration testing devices, fatigue failure of pins, and shorten the installation and debugging time. , The effect of reducing rotation jamming and avoiding fatigue failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

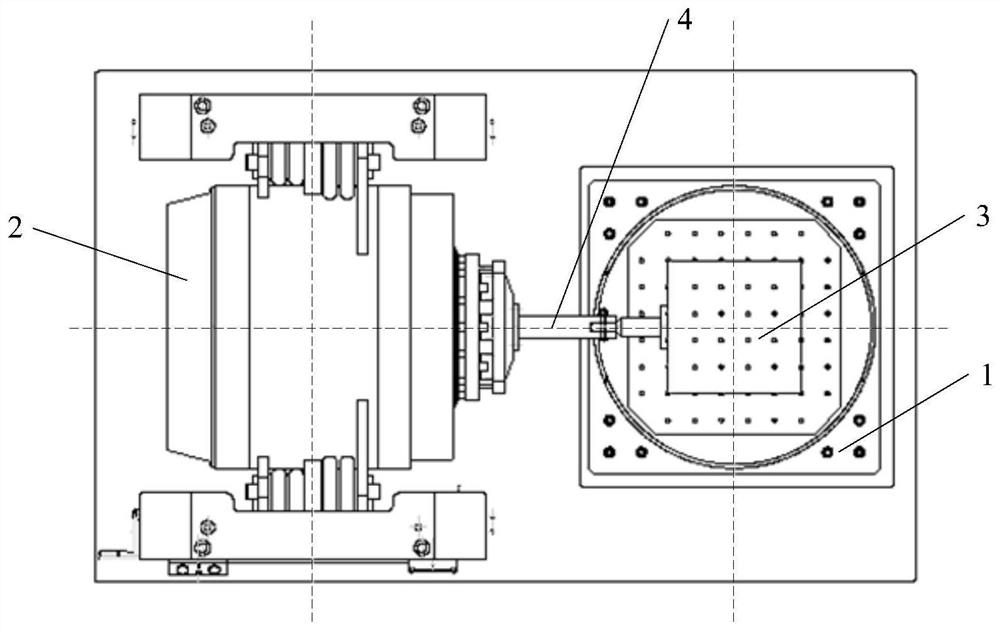

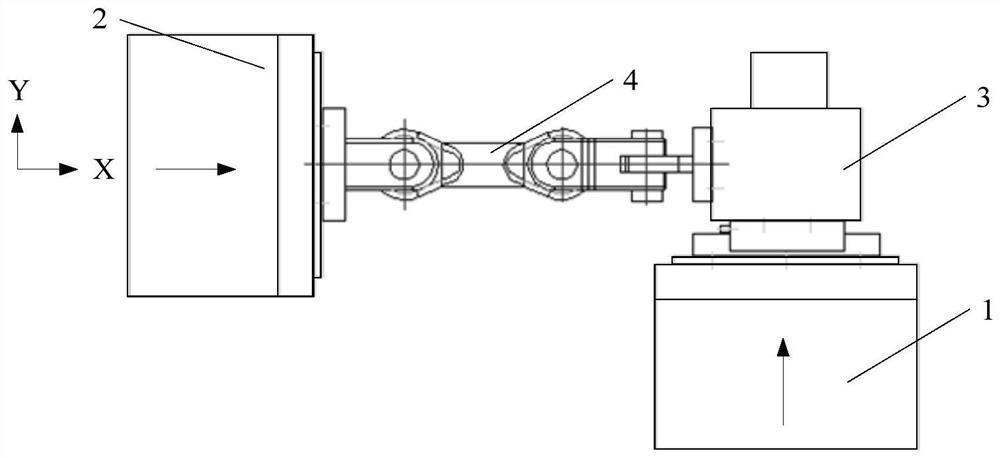

[0038] This embodiment provides a decoupling mechanism for two-axis synchronous vibration test, see Figure 3 to Figure 9 , comprising a hinged link 6 and a sliding assembly, the two ends of the hinged link 6 are respectively hinged with the horizontal vibration generator 2 and the workbench 3, the slide assembly is connected with the vertical vibration generator and the workbench 3 respectively, and the hinged link 6 can be Rotate in the vertical direction, the sliding direction of the sliding assembly is parallel to the vibration direction of the horizontal vibration generator 2 .

[0039] In practical applications, when the workbench 3 vibrates vertically under the action of the vertical vibration generator 1 , the hinged link 6 rotates relative to the workbench 3 through the transmission of force, thereby compensating for the vibration in the vertical direction. At the same time, when the table 3 vibrates horizontally under the action of the horizontal vibration generator ...

Embodiment 2

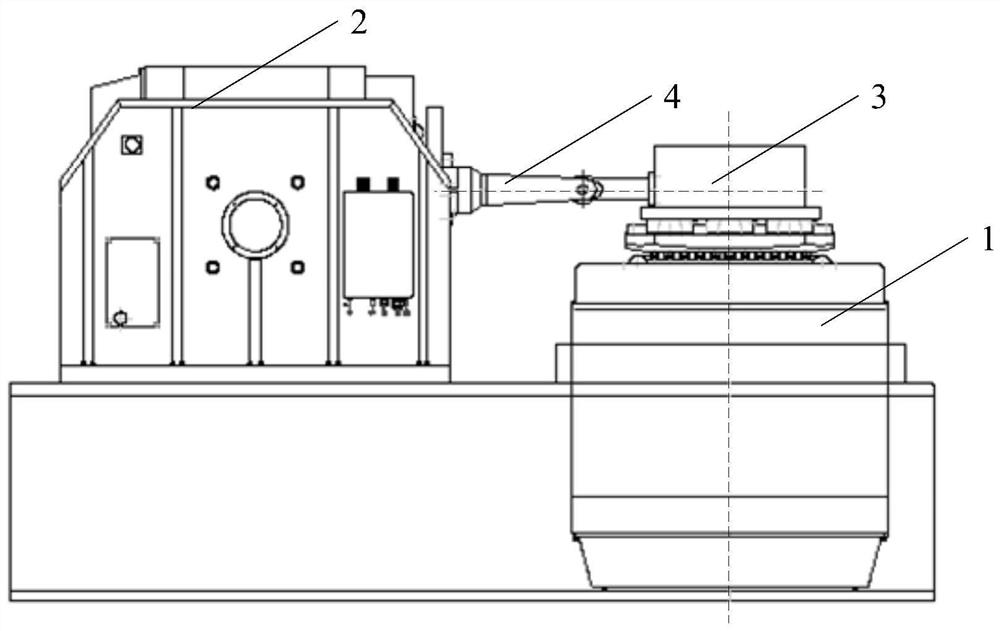

[0056] This embodiment provides a two-axis synchronous vibration test device, see Figure 10 to Figure 11 , including the workbench 3, the horizontal vibration generator 2, the vertical vibration generator 1 and the decoupling mechanism provided in Embodiment 1, the workbench 3, the horizontal vibration generator 2 and the vertical vibration generator 1 are all arranged on the base 12 superior.

[0057] Compared with the prior art, the beneficial effects of the two-axis synchronous vibration test device provided in this embodiment are basically the same as those of the decoupling mechanism provided in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com