Waterproof breathable film and preparation method thereof

A waterproof and breathable film and base film technology, applied in the field of film, can solve the problem that the waterproof and breathable effect of the waterproof breathable film needs to be strengthened, and achieve the effect of enhancing the waterproof and breathable function, enhancing the adhesion of the base film, and improving the waterproof and breathable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of polysulfone membrane: Polysulfone was dissolved in N,N-dimethylformamide (DMF) solvent, the weight percent of polysulfone was 15%, and the polysulfone solution was evenly spread on a clean glass plate. An aqueous phase solution is prepared, wherein the weight percentage of DMF is 1%, the weight percentage of sodium lauryl sulfate is 0.5%, and the balance is water. Soak the glass plate coated with the polysulfone solution in the aqueous phase solution for 5 minutes, take it out, and wash it with deionized water to obtain the polysulfone membrane.

[0040] Soak the polysulfone membrane in a methanol solution of dopamine with a pH of about 8.5 for 6 hours to form a layer of light black dopamine coating on the surface of the polysulfone membrane. Wherein, the concentration of dopamine is 10Mm, and the pH value is adjusted with Tris. The soaked polysulfone membrane was rinsed repeatedly with deionized water, and finally dried under inert gas to obtain the fir...

Embodiment 2

[0051] The polysulfone membrane was prepared by the same preparation method as in Example 1.

[0052] Soak the polysulfone membrane in a methanol solution of dopamine with a pH of about 8.5 for 7 hours to form a layer of light black dopamine coating on the surface of the polysulfone membrane. Wherein, the concentration of dopamine is 10Mm, and the pH value is adjusted with Tris. The soaked polysulfone membrane was rinsed repeatedly with deionized water, and finally dried under inert gas to obtain the first base membrane.

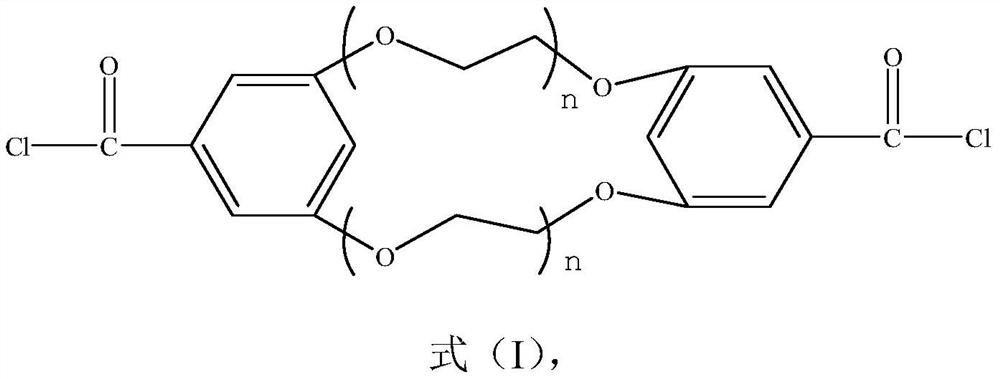

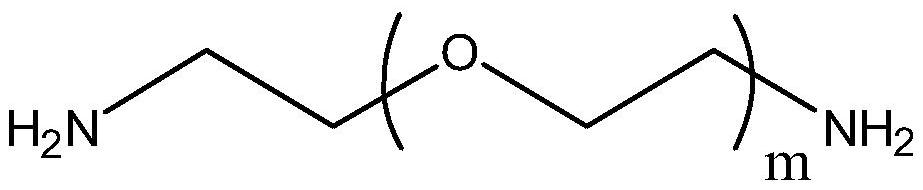

[0053] Then the polysulfone membrane (the first basement membrane) with dopamine coating is soaked in polyamine solution, soaking time is 0.5 hour, and the concentration of polyamine is 8mM, and the molecular structure of polyamine is as follows:

[0054]

[0055]Place the fully soaked first basement membrane on filter paper to absorb excess solution to obtain the second basement membrane, and transfer the second basement membrane to a clean glass dish. ...

Embodiment 3

[0061] The polysulfone membrane was prepared by the same preparation method as in Example 1.

[0062] Soak the polysulfone membrane in a methanol solution of dopamine with a pH of about 8.5 for 8 hours to form a layer of light black dopamine coating on the surface of the polysulfone membrane. Wherein, the concentration of dopamine is 10Mm, and the pH value is adjusted with Tris. The soaked polysulfone membrane was rinsed repeatedly with deionized water, and finally dried under inert gas to obtain the first base membrane.

[0063] Then the polysulfone membrane (the first basement membrane) with dopamine coating is soaked in polyamine solution, soaking time is 1.5 hours, and the concentration of polyamine is 12mM, and the molecular structure of polyamine is as follows:

[0064]

[0065] Place the fully soaked first basement membrane on filter paper to absorb excess solution to obtain the second basement membrane, and transfer the second basement membrane to a clean glass dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com