Charging pile

A technology of charging piles and charging lines, which is applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of convenient power supply line collection and lack of power supply line protection, and achieve the effect of good operation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

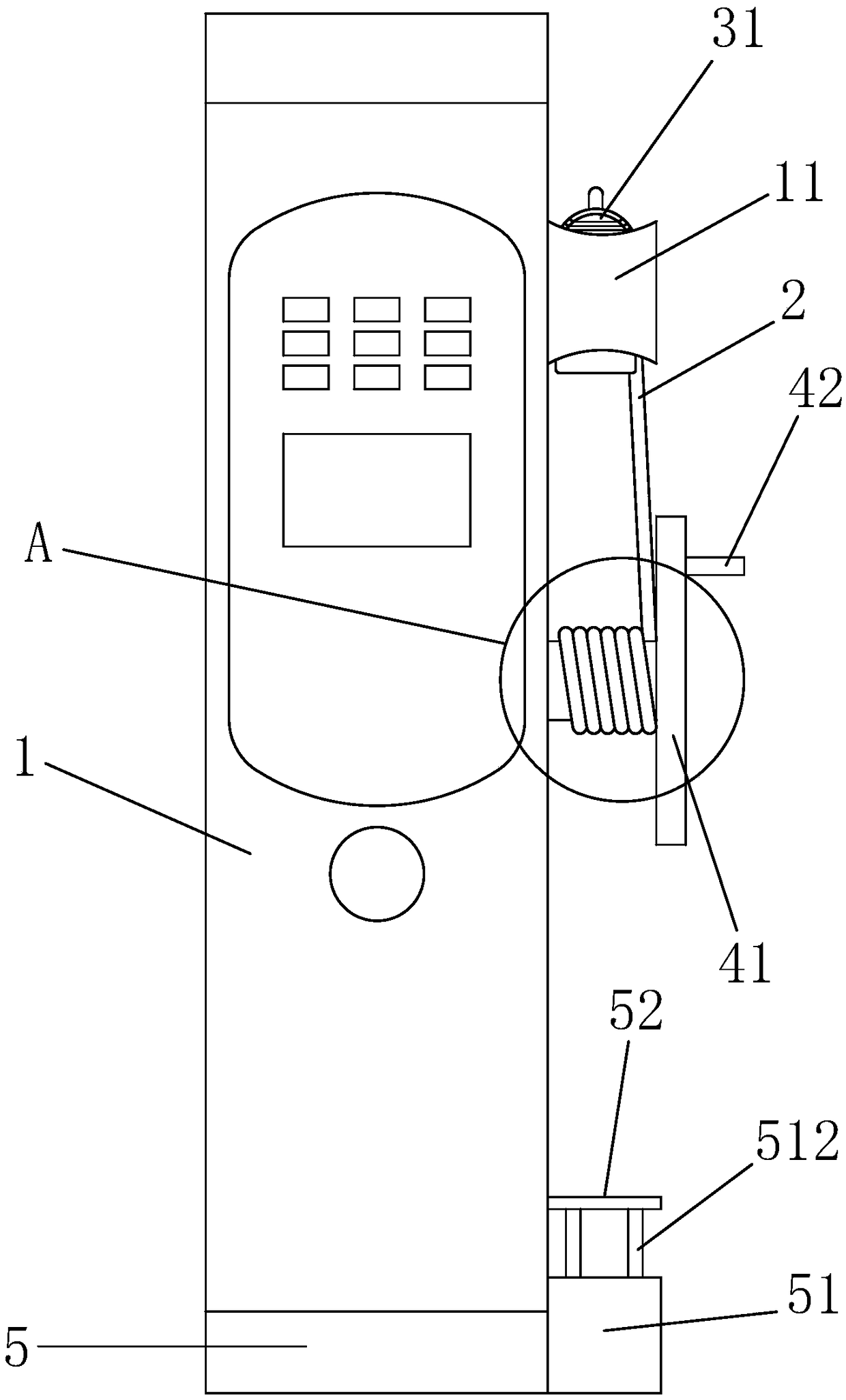

[0034] Embodiment 1: as Figure 1 to Figure 9 as shown in

[0035] A charging pile, including a pile body 1 and a charging circuit;

[0036] The charging circuit includes a power supply line 2 and an output socket 3 for docking with the input socket of the electric vehicle. The output socket is electrically connected to the power supply line. The output socket includes a socket base 31 and a socket barrel 32. One end of the socket barrel is open, and the socket barrel is another One end is sealed by the socket base, and a conductive pin 321 is arranged in the socket barrel;

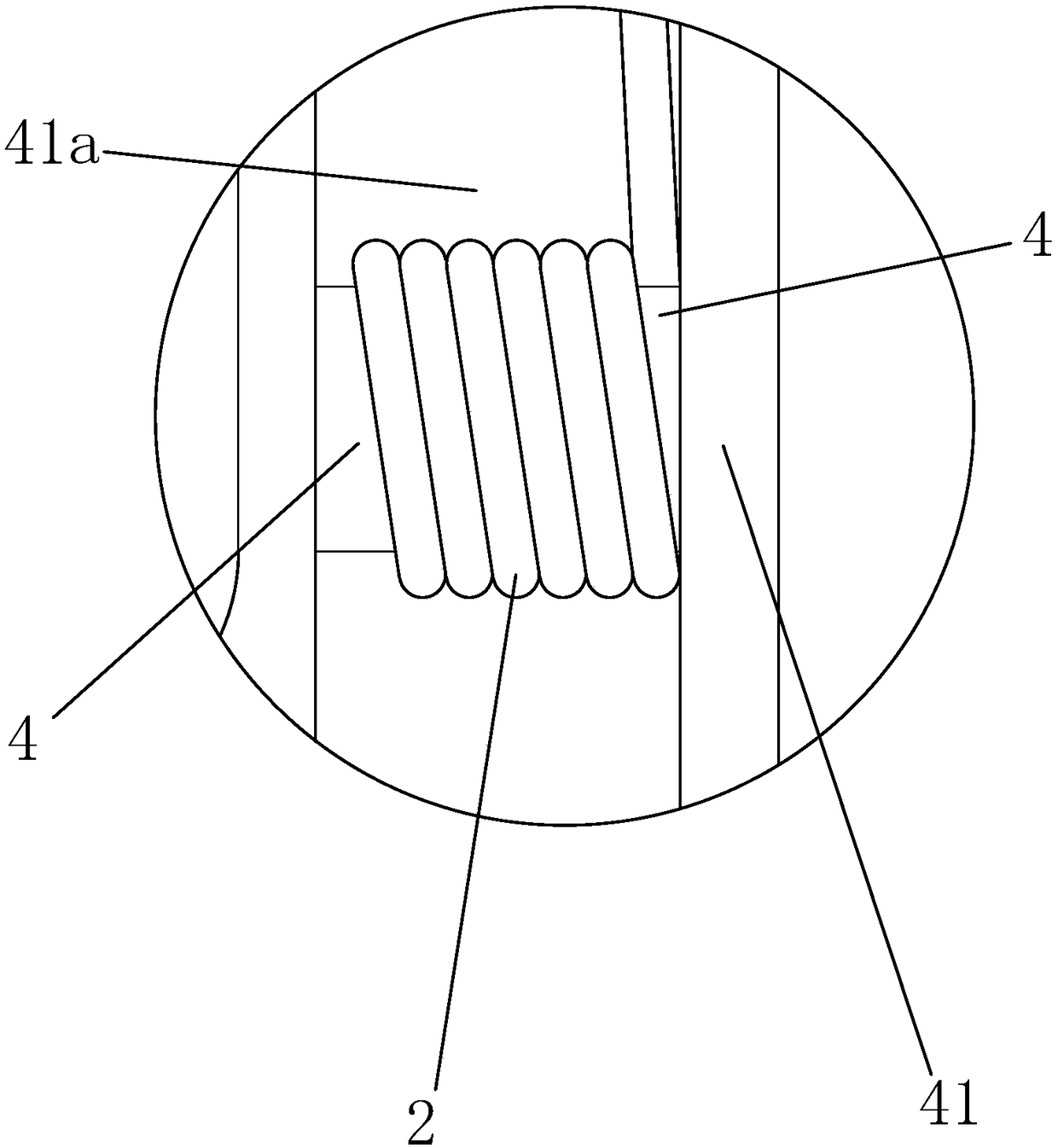

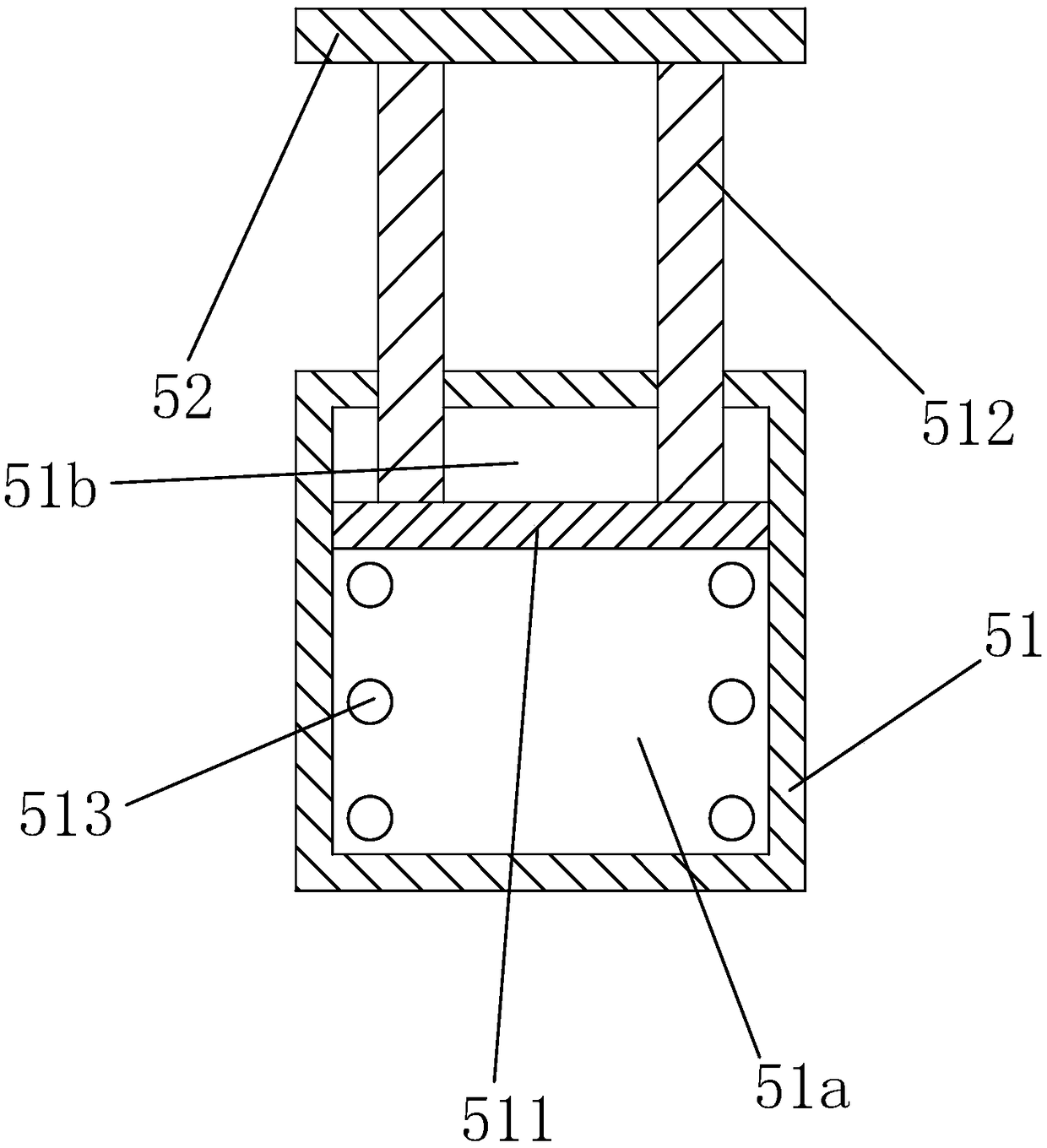

[0037] The pile body is provided with an inner cavity, and the pile body is provided with a rotating shaft 4 that is rotatably connected to the pile body. The rotating shaft and the pile body are rotated and sealed. The turntable 41 outside the main body forms a winding space 41a between the turntable and the pile body, a connecting buckle is provided on the power supply line, and the connecting buckle ...

Embodiment 2

[0051] Embodiment 2: based on embodiment 1, as Figure 10 to Figure 12 as shown,

[0052] The sleeve outer cover is provided with a swivel 81 that is rotatably connected with the sleeve, the swivel is provided with a pin lifting magnet 82, and the other end of the small diameter pin is provided with a passive magnet 83 that can be absorbed by the pin lifting magnet. Always stay outside the small diameter hole. The swivel is provided with a counterweight 84, and the passive magnetic block is fixed on the swivel through the counterweight. In this embodiment, when it is necessary to pull out the positioning pin (the lower end of the large-diameter pin leaves the positioning slot), the swivel can be turned directly so that the pin lifting magnet reaches the top, and the passive magnetic block is absorbed and moved up, driving the positioning pin to leave the positioning slot . Compared with directly pulling out the positioning pin upwards (the lower end of the large-diameter pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com