Soy sauce delicious flavor base material and preparation method thereof

A umami and soy sauce technology, applied in food science and other fields, can solve problems such as how to improve the quality of soy sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

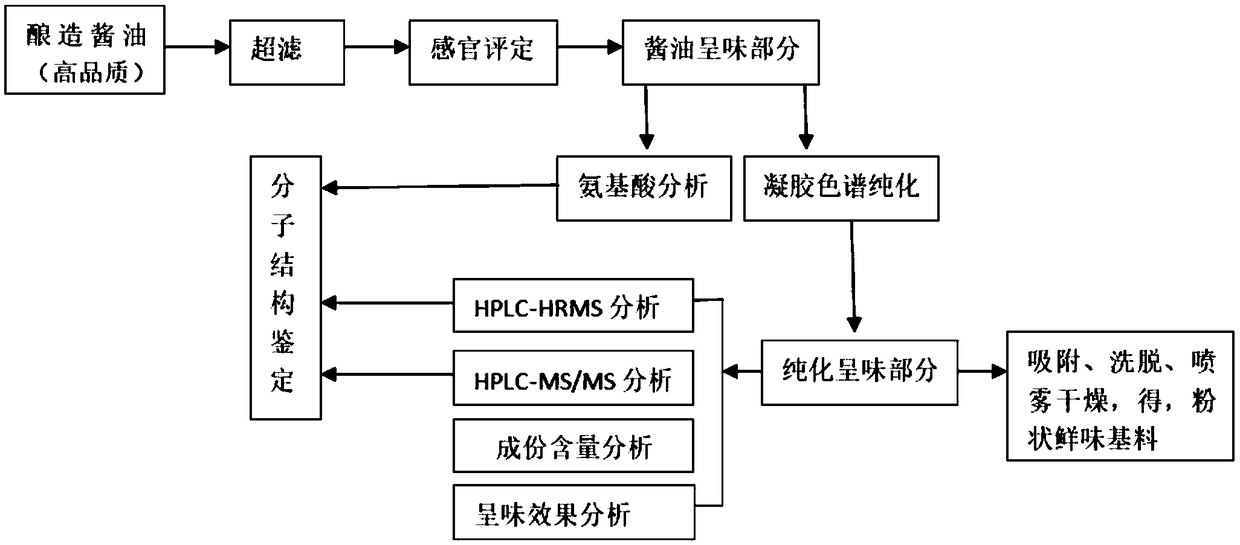

Method used

Image

Examples

preparation example Construction

[0038] In some embodiments, the present invention provides a kind of preparation method of soy sauce umami taste base material, comprises the following steps:

[0039] 1) Firstly, high-quality soy sauce is passed through ultrafiltration membranes with pore sizes of 10000Da, 5000Da and 1000Da in sequence, and the permeate is collected, concentrated, freeze-dried, and stored in a desiccator for future use;

[0040] 2) Prepare a 20 mg / mL solution of the lyophilized powder and deionized water obtained from the above ultrafiltration separation, take 3 mL of the solution onto the column, and elute with deionized water at a flow rate of 1 mL / min. Collect in separate tubes of 2ml; use UV-2100 ultraviolet-visible spectrophotometer to detect at 220nm wavelength, get P-I, P-II, P-III and P-IV separated peak components, combine the collected components under the same peak, concentrate and freeze dry and ready for use;

[0041] 3) The degree of umami enhancement of the above-mentioned lyo...

Embodiment 1

[0049] A kind of embodiment of the preparation method of soy sauce umami taste base material among the present invention , including the following steps:

[0050] 1) First, high-quality soy sauce (high-quality soy sauce is Haitian Jinbiao light soy sauce, which can be purchased by the public, and the other examples are the same) is passed through ultrafiltration membranes with pore sizes of 10000Da, 5000Da and 1000Da in sequence, and the permeate is collected and then concentrated , freeze-dried and placed in a desiccator for future use;

[0051] 2) Prepare a 20 mg / mL solution of the lyophilized powder and deionized water obtained from the above ultrafiltration separation, take 3 mL of the solution onto the column, and elute with deionized water at a flow rate of 1 mL / min. Collect in separate tubes of 2ml; use UV-2100 ultraviolet-visible spectrophotometer to detect at 220nm wavelength, get P-I, P-II, P-III and P-IV separated peak components, combine the collected components ...

Embodiment 2

[0061] A kind of embodiment of the preparation method of soy sauce umami taste base material among the present invention , including the following steps:

[0062] 1) Firstly, high-quality soy sauce is passed through ultrafiltration membranes with pore sizes of 10000Da, 5000Da and 1000Da in sequence, and the permeate is collected, concentrated, freeze-dried, and stored in a desiccator for future use;

[0063] 2) Prepare a 20 mg / mL solution of the lyophilized powder and deionized water obtained from the above ultrafiltration separation, take 3 mL of the solution onto the column, and elute with deionized water at a flow rate of 1 mL / min. Collect in separate tubes of 2ml; use UV-2100 ultraviolet-visible spectrophotometer to detect at 220nm wavelength, get P-I, P-II, P-III and P-IV separated peak components, combine the collected components under the same peak, concentrate and freeze dry and ready for use;

[0064] 3) The degree of umami enhancement of the above-mentioned lyophi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com