Sensor Integration for Clutch Disconnectors

A clutch and separator technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of a large number of separate components, high cost, and large structural space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

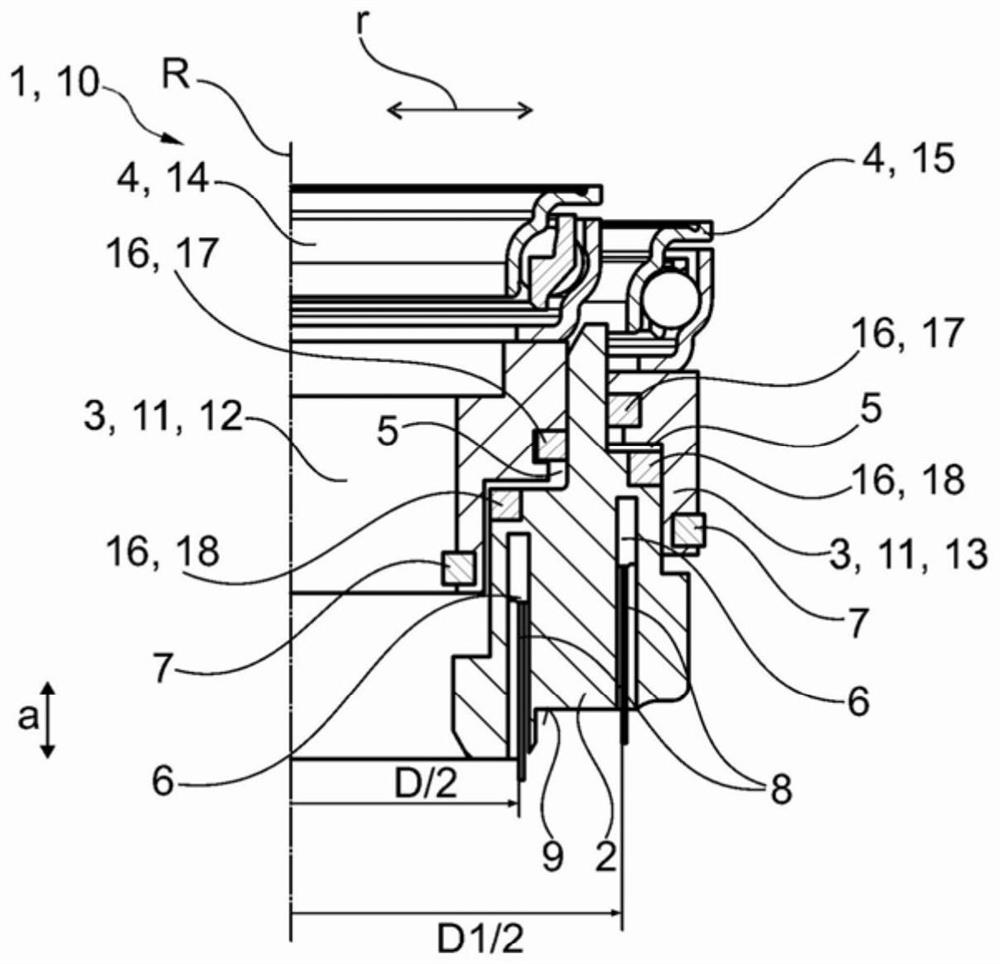

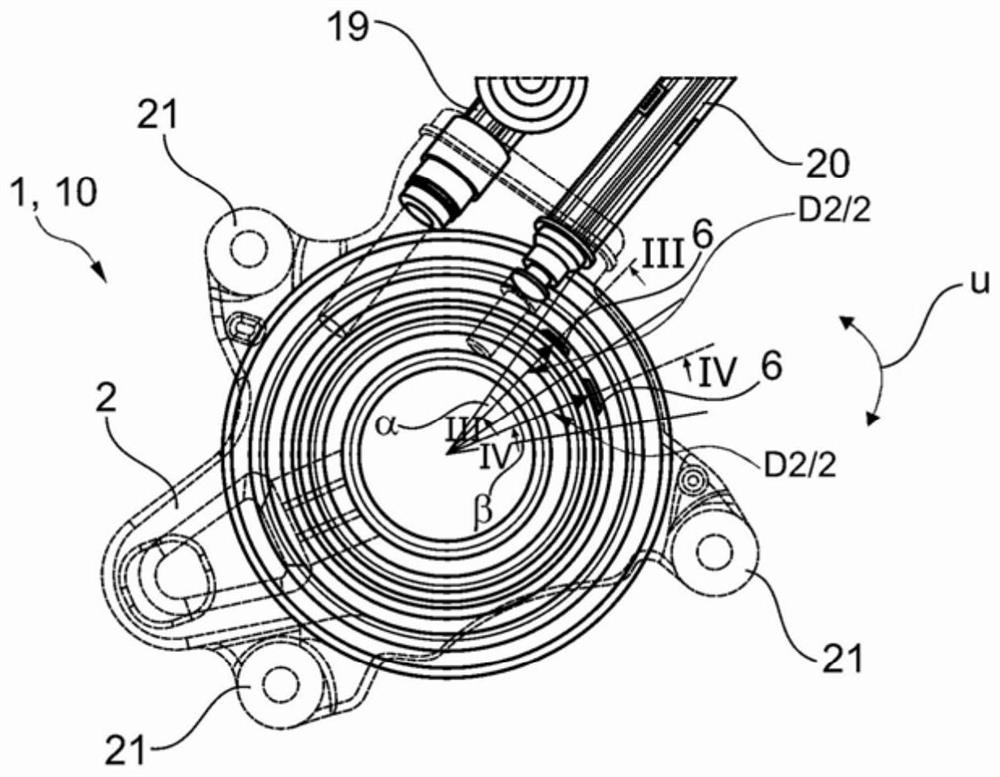

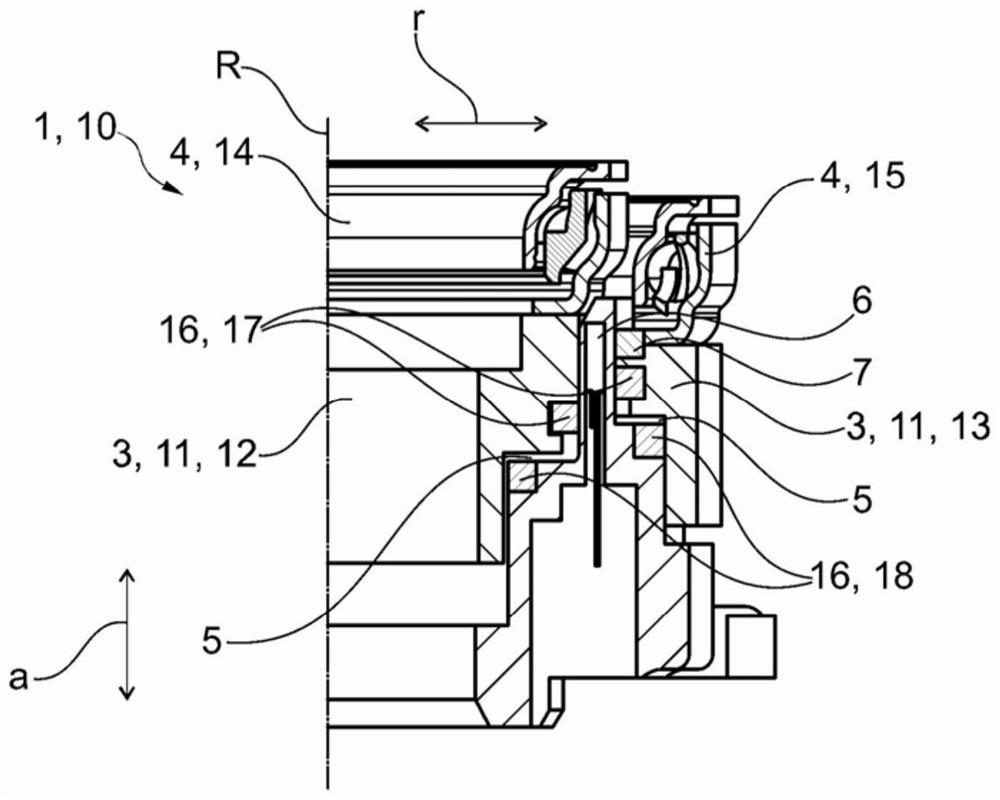

[0026] figure 1 An exemplary first embodiment of the clutch release 1 is shown. The clutch release 1 has a housing 2 (see also figure 2 ), in which the two pistons 3, 3 are accommodated. Pistons 3 , 3 are axially displaceable in housing 2 in order to actuate a release bearing 4 in each case. In order to move the piston 3 axially in the housing 2 , each piston 3 forms with the housing 2 a pressure chamber 5 which can be pressurized by means of hydraulic fluid, whereby the piston 3 can be moved along the axis of rotation R .

[0027] Two sensors 6 are accommodated in the housing 2 , which are used to detect the position of a piston 3 in each case. For this, a magnet 7 is attached to each piston 3 , the position of which can be determined via the associated sensor 6 . The sensor 6 is accommodated in the housing 2 in a recess 8 which is open towards the side 9 of the housing 2 facing away from the release bearing. The sensor 6 can thus be inserted into the housing 2 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com