Thickness-adjustable type slicer

An adjustable, slicer technology, applied in metal processing and other directions, can solve the problems of difficulty in realizing the thickness of fruit and vegetable slices, different thicknesses of fruit and vegetable slices, and high labor intensity, and achieve a simple and reasonable structure, fast slicing speed and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

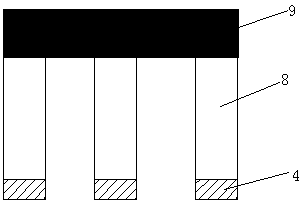

[0021] A thickness-adjustable slicer, comprising a base 1, jaws 2 and a cutting blade set 3 placed on the left and right sides of the base respectively, the jaws and the cutting blade set are on the same horizontal plane, and the opening of the jaws faces the cutting blade set , the cutting edge 4 of the cutting blade set faces the jaws.

[0022] The left side of the base is provided with a cylinder 5, the cylinder output shaft 6 faces the cutting blade group, and the cylinder output shaft is connected with the jaws; the base is also provided with a controller 7, and the jaws are provided with a gravity sensor to control The device is connected to the cylinder and the gravity sensor respectively.

[0023] The cutting blade group is composed of evenly distributed blades 8 and cutter heads 9, and several blades are placed in parallel; Corresponding positions of the baffle are respectively provided with bar-shaped installation openings 12 .

[0024] One end of the blade is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com