Handle device with a surface-flush handle

A handle, outer surface technology, applied in the field of moving parts, can solve problems such as loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

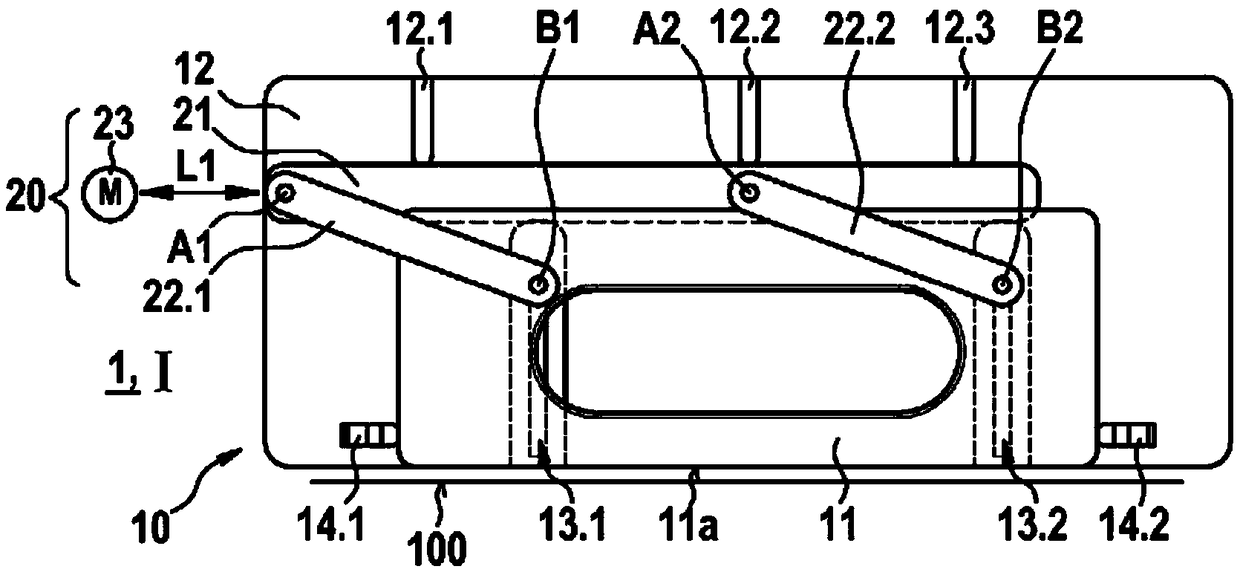

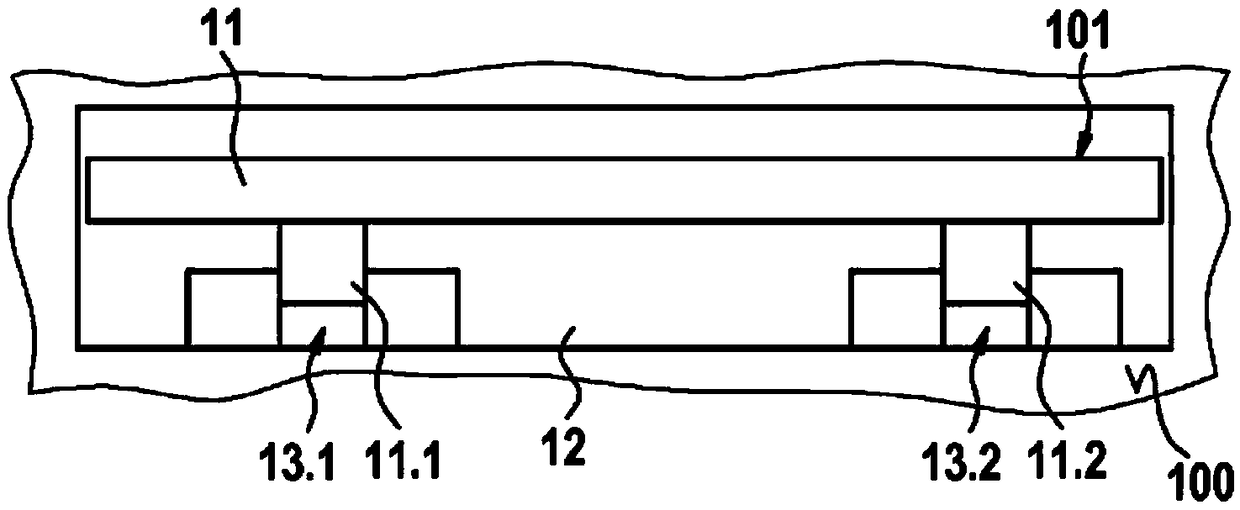

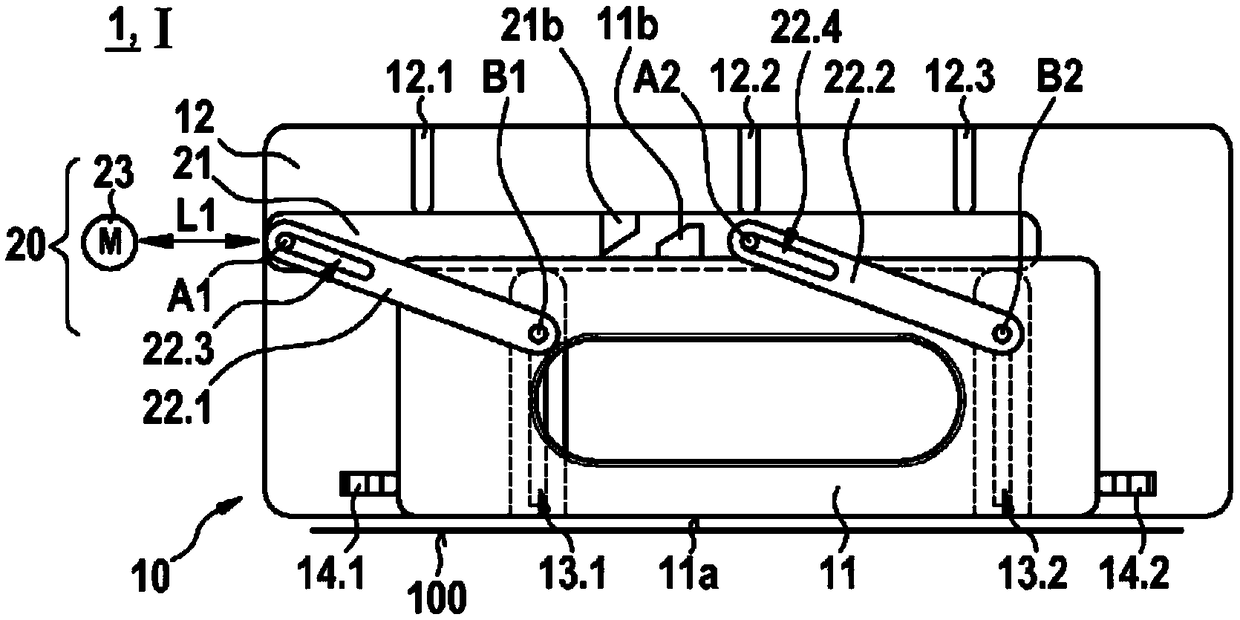

[0046] Figures 1a to 3The handle device 10 according to the invention is shown with a flush handle part 11 in the rest position I. Said handle part 11 is used according to the invention for operating, for example opening a movable part, such as a vehicle door. The handle arrangement 10 is fastened here to a bearing element 12 which can serve as a housing or frame structure for fixing the handle arrangement 10 to the movable part. In order to finally be able to operate the handle part 11, by means of the drive unit 20 it is possible to Figure 1a with Figure 2a shown in the surface-flush rest position I and in the Figure 2e with image 3 The handle part 11 is driven between the working position II shown in . as by Figure 1a As can be seen, the handle part 11 in the rest position I is arranged flush with the outer surface 11 a of the outer surface 100 of the movable part. exist Figure 2e with 3 In the working position II shown in , the handle part 11 is moved out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com