Truck bucket pit repairing device

A body and pit technology, applied in vehicle parts, transportation and packaging, etc., can solve problems such as affecting the normal use of trucks and reducing the service life of the body, and achieve the effects of low price, convenient loading and shortening service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

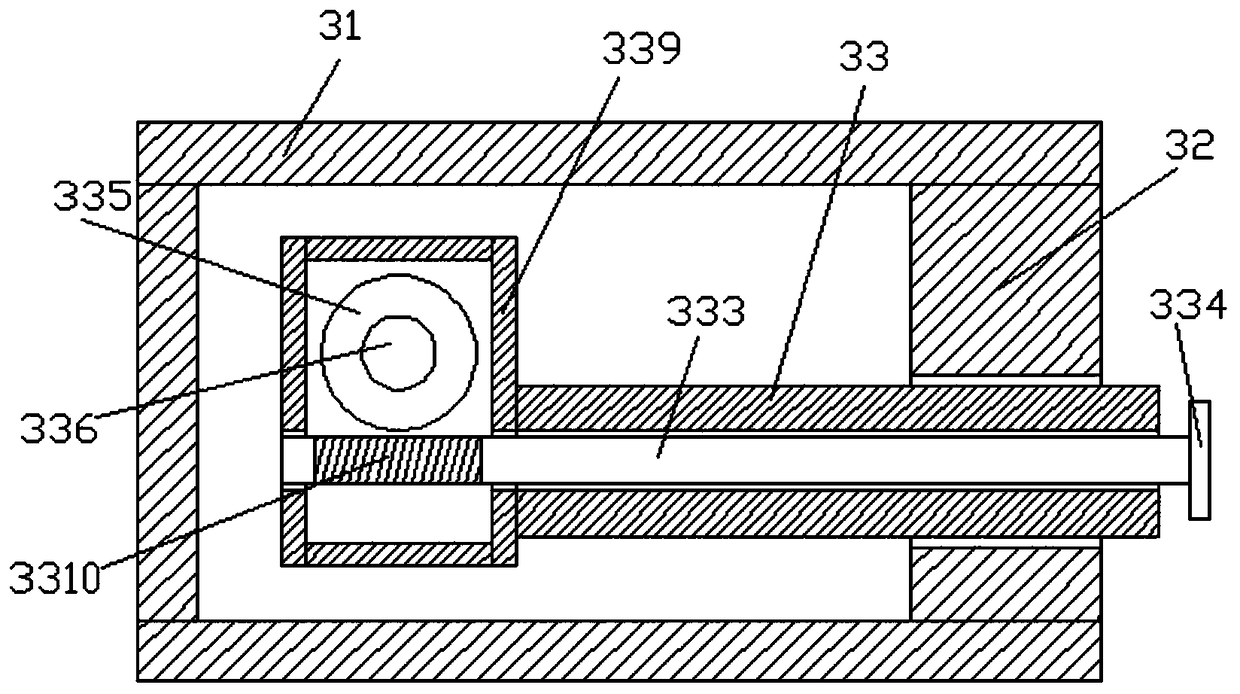

[0027] Such as Figure 1 to Figure 7 , Figure 9 As shown, a truck body pit repair device includes a truck body 1, the bottom of the truck body 1 is provided with a load plate 2, the load plate 2 is fixedly connected with the vehicle body 1, and the lower surface of the load plate 2 is provided with There is a bracket, and the bracket includes a crossbeam 6 and a longitudinal beam 5, the crossbeam 6 and the longitudinal beam 5 are arranged at ninety degrees, and both the crossbeam 6 and the longitudinal beam 5 are fixedly connected to the lower surface of the bearing plate 2, and the crossbeam 6 and the longitudinal beam 5 is provided with a support shell 3, the support shell 3 is fixedly connected with the surface of the cross beam 6 and the longitudinal beam 5, the support assembly 33 is arranged inside the support shell 3, and the support assembly 33 is connected with the support shell 3 mating connections. Trucks are widely used in the transportation industry because of ...

Embodiment 2

[0034] The difference with the above-mentioned embodiment is:

[0035] Such as Figure 8 As shown, the cross-section of the support rod 331 can also be rectangular, so that in the process of pulling back and forth and turning left and right, the lower surface of the support rod 331 can fit better with the inner surface of the rectangular through hole, making the movement easier. smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com