Gauze winding and collecting device for textile factory

A collection device and textile factory technology, applied in the direction of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of troublesome cleaning, troublesome operation, accumulation of dust and waste, etc., to achieve simple and convenient operation, reduce trouble, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

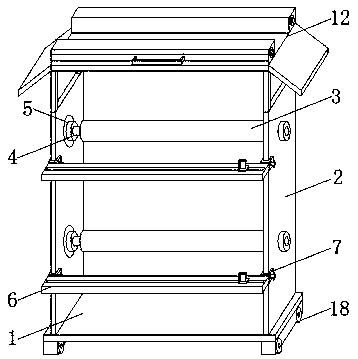

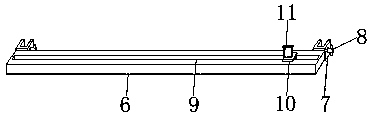

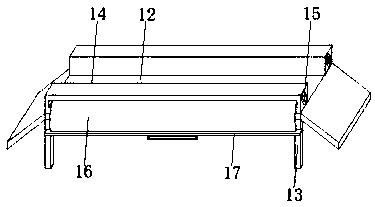

[0022] Example: such as figure 1 , figure 2 and image 3 As shown, a gauze winding and collecting device for textile mills of the present invention includes a load-bearing base plate 1, side brackets 2 are fixedly installed on the top of the load-bearing base plate 1 near the edges of both sides, and the inner upper and lower parts of the two groups of side brackets 2 are all fixed. A winding drum 3 is provided, and the winding drum 3 has played a winding and collecting effect on gauze, etc., and the inner walls of the two groups of winding drums 3 are movably interspersed with movable shafts 4, and the two ends of the two groups of movable shafts 4 are movably provided with spiral discs 5, four One end of the set of spiral discs 5 is fixedly connected with the two sets of side supports 2, and the front parts of the two sets of side supports 2 are provided with cutting supports 6 at the positions close to the upper and lower parts, and one end of the two sets of cutting supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com