Brazed honeycomb sound absorbing structure with micro-seam

A micro-slit and honeycomb technology, applied in the field of sound absorption and noise reduction, can solve the problems of being unable to adapt to harsh environments, harmful to human health, poor weather resistance, etc., to achieve improved sound absorption effects, easy cleaning, and good sound absorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

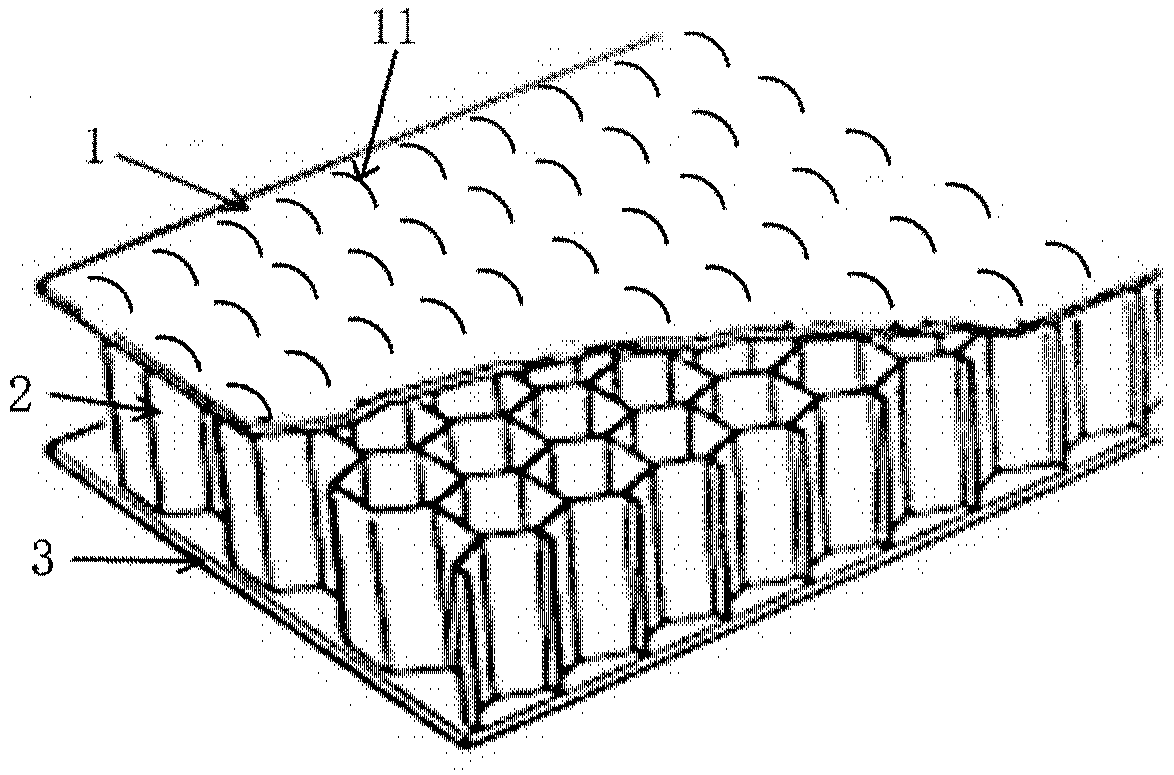

[0026] In one embodiment, as figure 1 As shown, the brazed micro-slit honeycomb sound-absorbing structure includes: a front panel, an intermediate core layer, and a rear panel, and the front panel, the rear panel, and the intermediate core layer are connected by brazing and welding. After installing the brazed micro-slit honeycomb sound-absorbing structure on an installation surface 6 (such as a wall), there is a cavity 5 between the brazed micro-slit honeycomb sound-absorbing structure 4 and the installation wall 6, The cavity depth is D2, and the core layer thickness is D1, such as figure 2 shown.

[0027] The existing panel and the honeycomb interlayer are mainly connected by adhesive bonding. Compared with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com