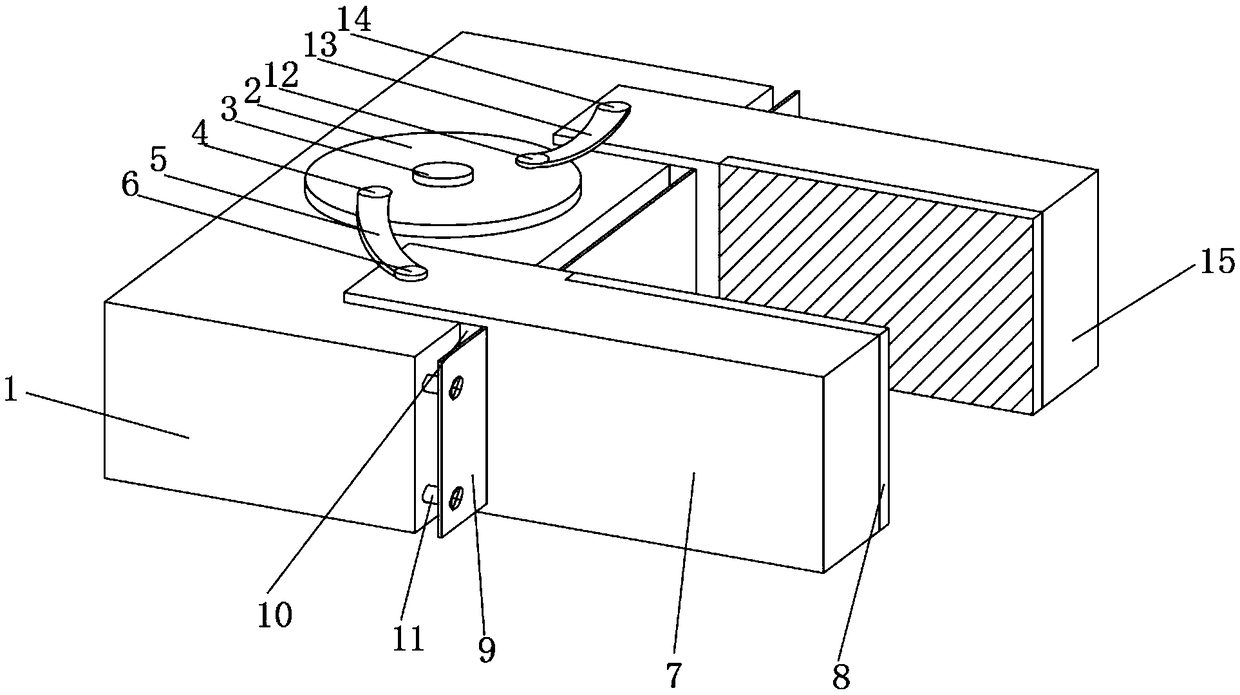

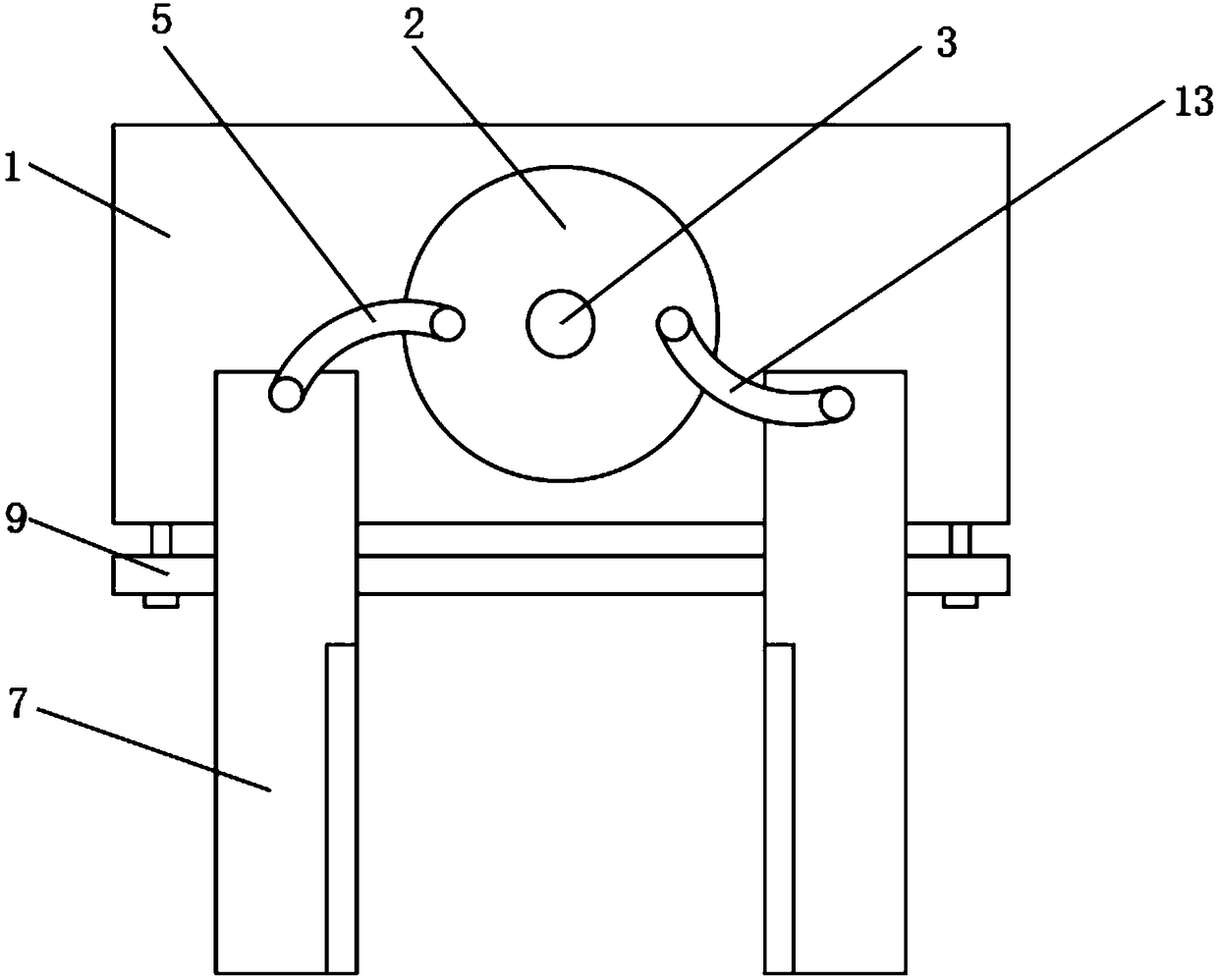

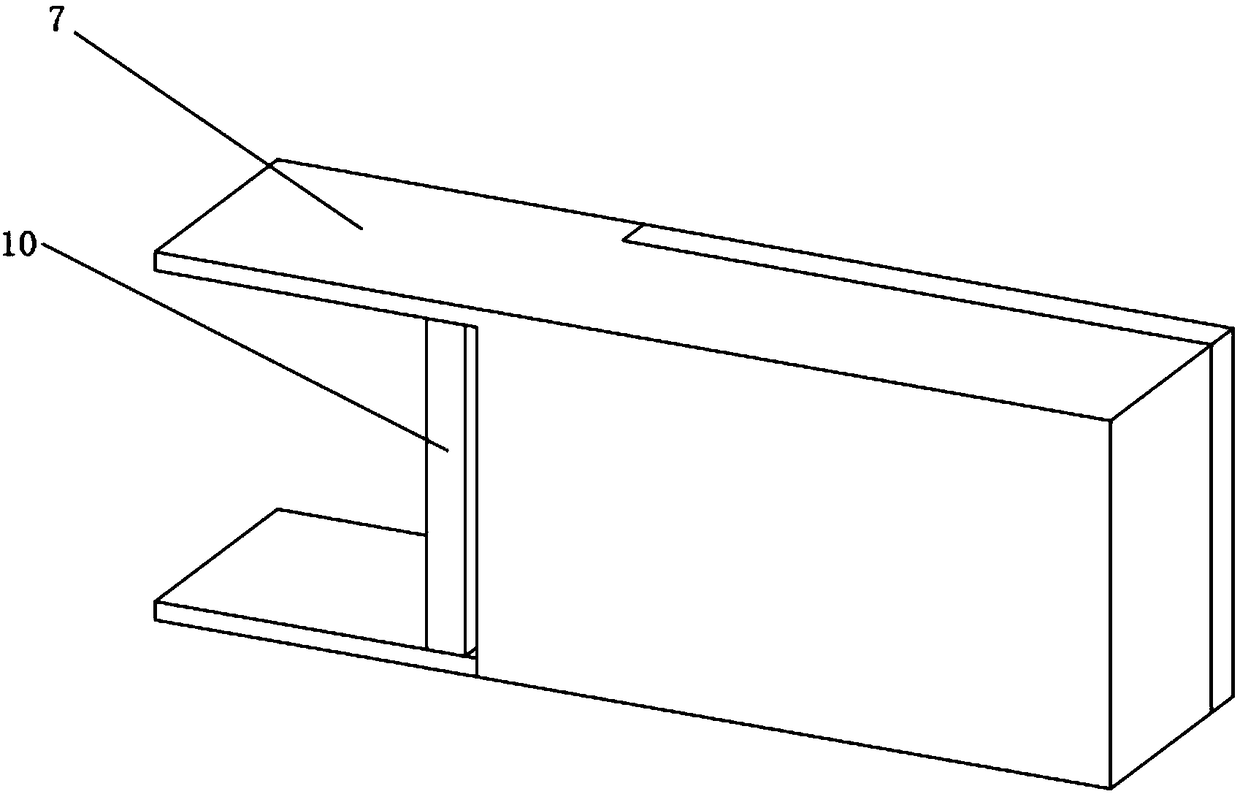

Clamping mechanism of medical robot

A clamping mechanism and robot technology, applied in the field of robots, can solve the problems of surface damage of the clamping object, complex clamping mechanism structure, general clamping effect, etc., and achieve the effect of avoiding maintenance difficulties, simple structure, and avoiding water contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Super-hydrophobic wear-resistant coating, including the following raw materials in parts by weight: 90 parts of copper sulfate, 60 parts of methacryloxyethyl phosphate, 20 parts of vinyl terephthalic acid, 225 parts of ethanol, diethylene triethylene 50 parts of amine pentaacetic dianhydride, 60 parts of ethyl orthosilicate, 150 parts of zinc oxide, 90 parts of manganese dioxide, 15 parts of licorice essence, 65 parts of tetraethylenepentamine, and 600 parts of water.

[0032] The preparation method of superhydrophobic wear-resistant coating, comprises the following steps:

[0033] Step 1, mixing copper sulfate, methacryloyloxyethyl phosphate, and vinyl terephthalic acid, adding to ethanol and stirring evenly to obtain mixture 1;

[0034] Step 2: Mix water, diethylenetriaminepentaacetic dianhydride, and ethyl orthosilicate, heat to 200-300°C, keep for 5 hours, add zinc oxide, manganese dioxide, and licorice essence, stir evenly with magnetic force, and rotate Be 1330r / ...

Embodiment 2

[0038] Super-hydrophobic wear-resistant coating, including the following raw materials in parts by weight: 80 parts of copper sulfate, 40 parts of methacryloxyethyl phosphate, 10 parts of vinyl terephthalic acid, 220 parts of ethanol, diethylene triethylene 40 parts of amine pentaacetic dianhydride, 30 parts of ethyl orthosilicate, 100 parts of zinc oxide, 40 parts of manganese dioxide, 20 parts of licorice essence, 70 parts of tetraethylenepentamine, and 800 parts of water.

[0039] The preparation method of superhydrophobic wear-resistant coating, comprises the following steps:

[0040] Step 1, mixing copper sulfate, methacryloxyethyl phosphate, and vinyl terephthalic acid, adding to ethanol and stirring evenly to obtain mixture 1;

[0041] Step 2: Mix water, diethylenetriaminepentaacetic dianhydride, and ethyl orthosilicate, heat to 200-300°C, keep for 6 hours, add zinc oxide, manganese dioxide, and licorice essence, stir evenly with magnetic force, Be 1300r / min, obtain mixt...

Embodiment 3

[0045] Super-hydrophobic wear-resistant coating, including the following raw materials in parts by weight: 100 parts of copper sulfate, 90 parts of methacryloxyethyl phosphate, 30 parts of vinyl terephthalic acid, 230 parts of ethanol, diethylene triethylene 60 parts of amine pentaacetic dianhydride, 90 parts of ethyl orthosilicate, 200 parts of zinc oxide, 120 parts of manganese dioxide, 10 parts of licorice essence, 60 parts of tetraethylenepentamine, 400 parts of water.

[0046] The preparation method of superhydrophobic wear-resistant coating, comprises the following steps:

[0047] Step 1, mixing copper sulfate, methacryloxyethyl phosphate, and vinyl terephthalic acid, adding to ethanol and stirring evenly to obtain mixture 1;

[0048] Step 2: Mix water, diethylenetriaminepentaacetic dianhydride, and ethyl orthosilicate, heat to 200-300°C, keep for 4 hours, add zinc oxide, manganese dioxide, and licorice essence, stir evenly with magnetic force, and rotate Be 1400r / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com