A modular converter device, combined converter and control method

A current conversion device and control method technology, which is applied in the direction of control/regulation system, emergency protection circuit device, output power conversion device, etc., can solve the problem of uncertain length of ice-melting lines, high requirements for the working range of the device, and variable load resistance. Determination and other issues to achieve the effect of high cost performance, low cost and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below with reference to the accompanying drawings.

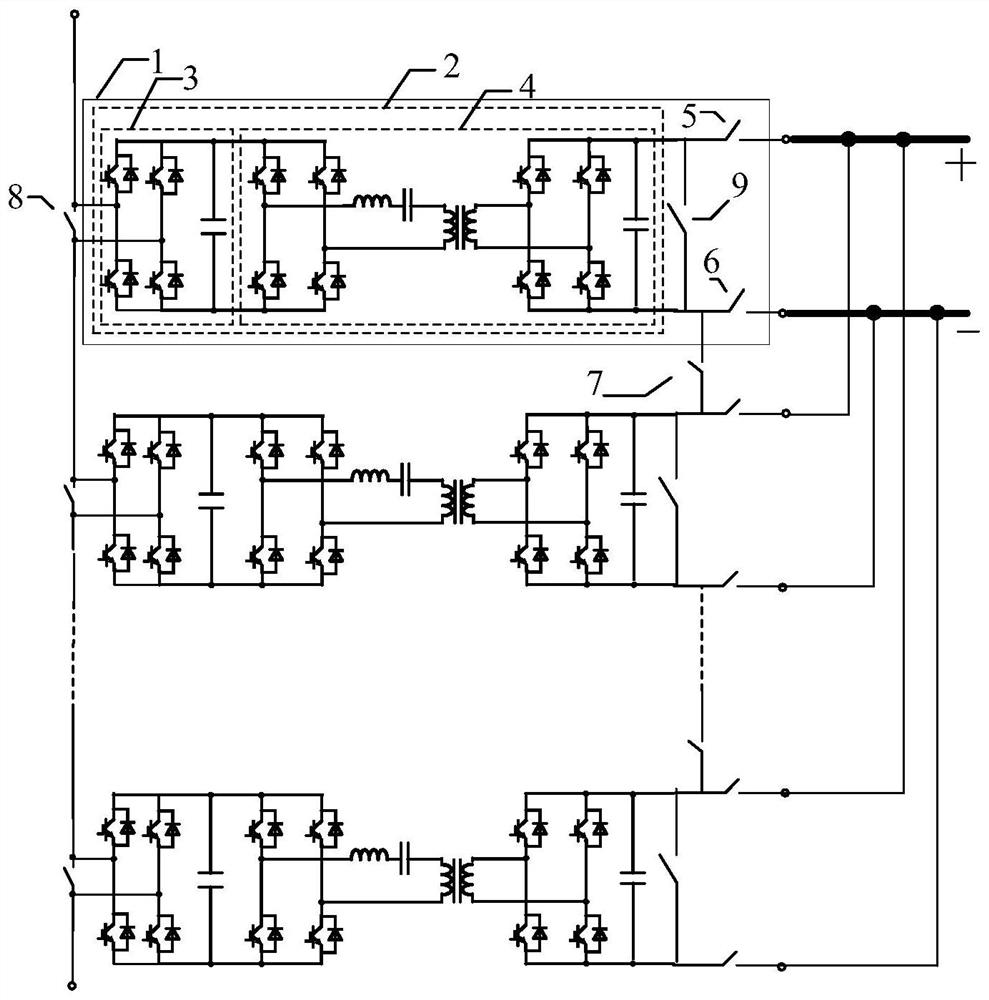

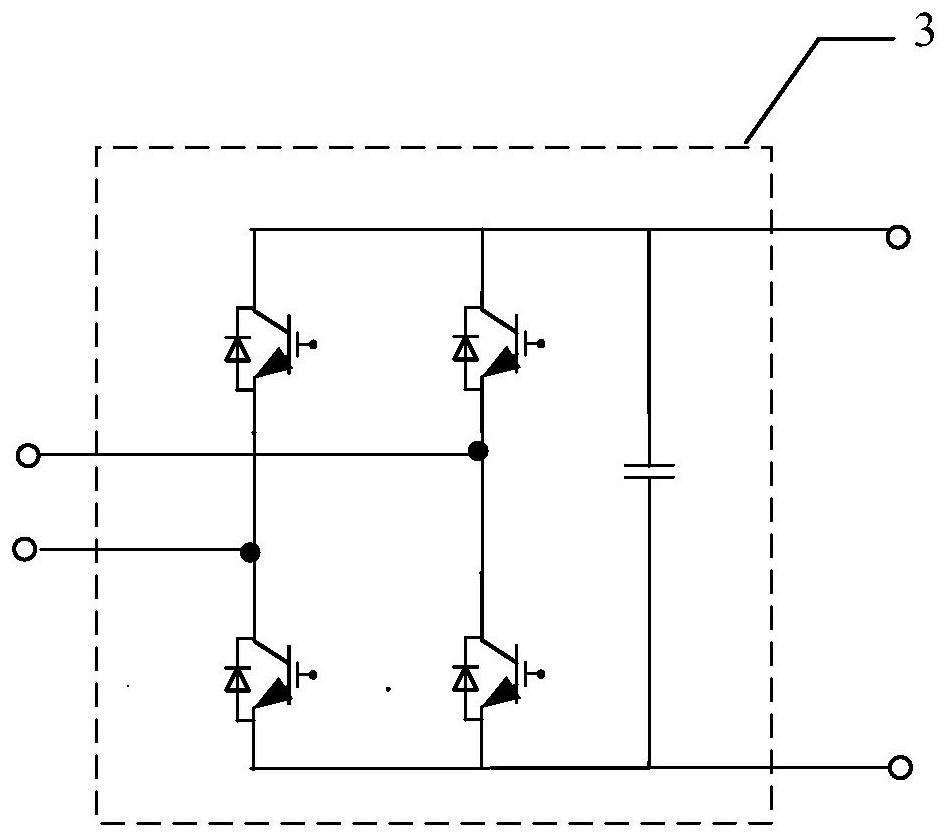

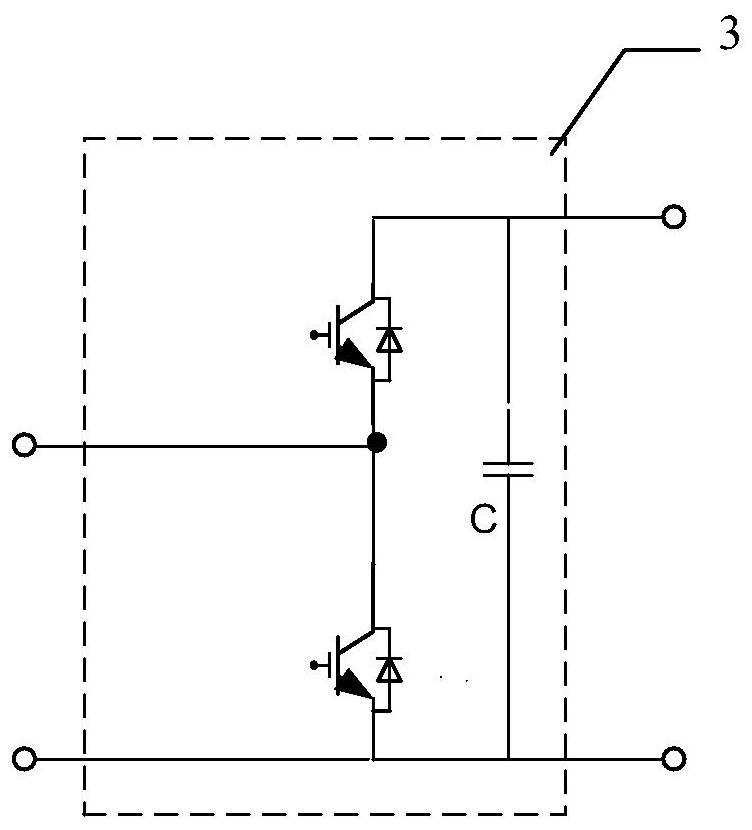

[0050] like figure 1 As shown, a modular variable flow device 1, the apparatus includes at least one two-stage converter 2, a positive switch 5, and a negative switch 6; the bipolar converter includes a direct transformer 3 and a straight straight Converter 4, the alternating conversion can realize the conversion of AC and DC, the direct transformer can realize the amplitude of the amplitude between DC and DC power; the DC output terminal of the alternar conversion and the straight conversion A DC input connection; the DC output of all straight conversors is connected to one end of the positive electrode switch, and the other end of the positive electrode switch is a positive electrode of the modular variable flow device; the DC output negative electrode is connected to one end of the negative switch, the negative switch One end is an negative electrode of the modular variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com