Method for establishing buckling and hanging system by using arch rib structure of edge span

A rib structure and side-span technology, which is applied in construction, bridge construction, erection/assembly of bridges, etc., can solve the problems of reinforced concrete consumption, environmental pollution, and difficulty, and achieve material cost saving, convenient construction, and large bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

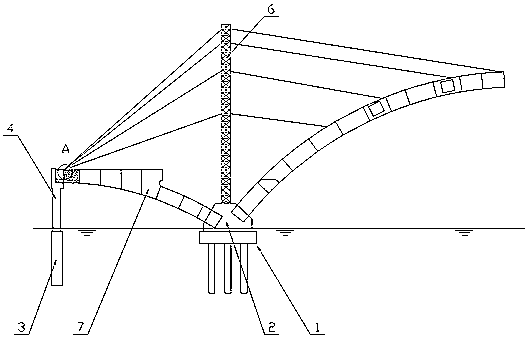

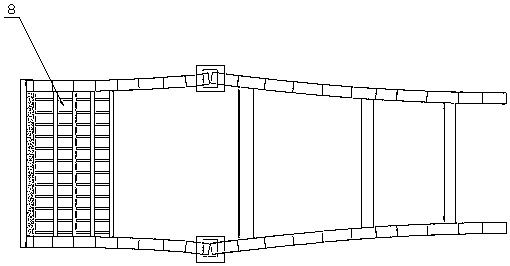

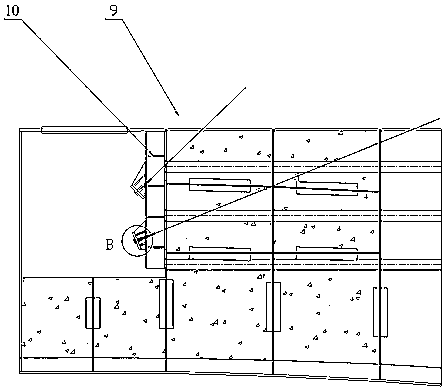

[0037] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 11 Shown: A method for establishing a buckle-hanging system using the side-span arch rib structure, followed by the following steps:

[0038] First, carry out the construction of the abutment foundation 1 and the abutment 2, the construction of the cover beam foundation 3 and the cover beam 4, and then pre-embed the embedded parts of the buckle foundation on the top of the abutment 2, and install it before pouring the concrete of the abutment 2 For the first section 5 of the side-span arch rib, after the concrete strength of the abutment 2 reaches the requirement, the steel strands in the first section 5 are stretched and grouted to consolidate the first section 5 and the abutment 2; then use The crane installs the buckle tower 6 on the abutment 2, and at the same time installs the side-span arch rib 7 and the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com