Cutting table board for firework paper tubes

A table top and paper tube technology, which is applied in the field of firework paper tube cutting table top, can solve the problems of operator cuts, dangerous pushing methods, low work efficiency, etc., and achieve the effect of eliminating accidental injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

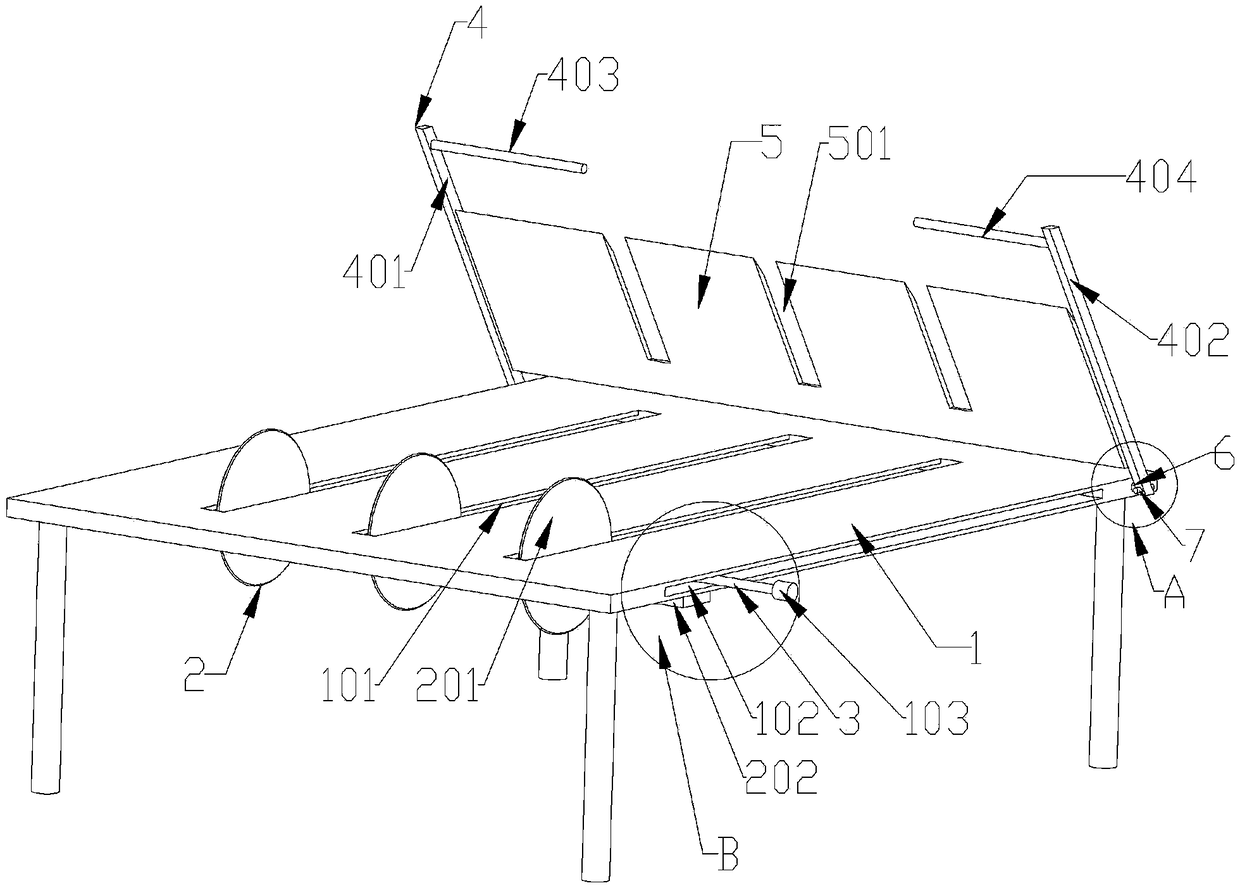

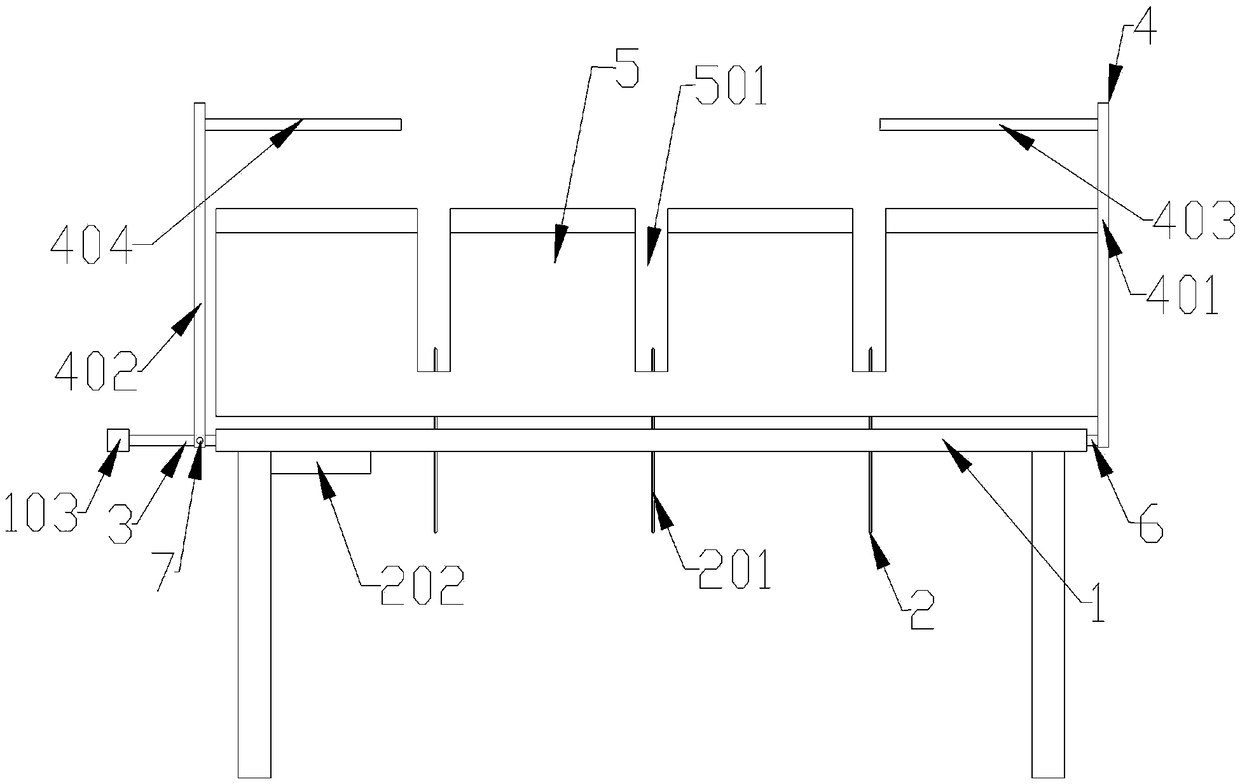

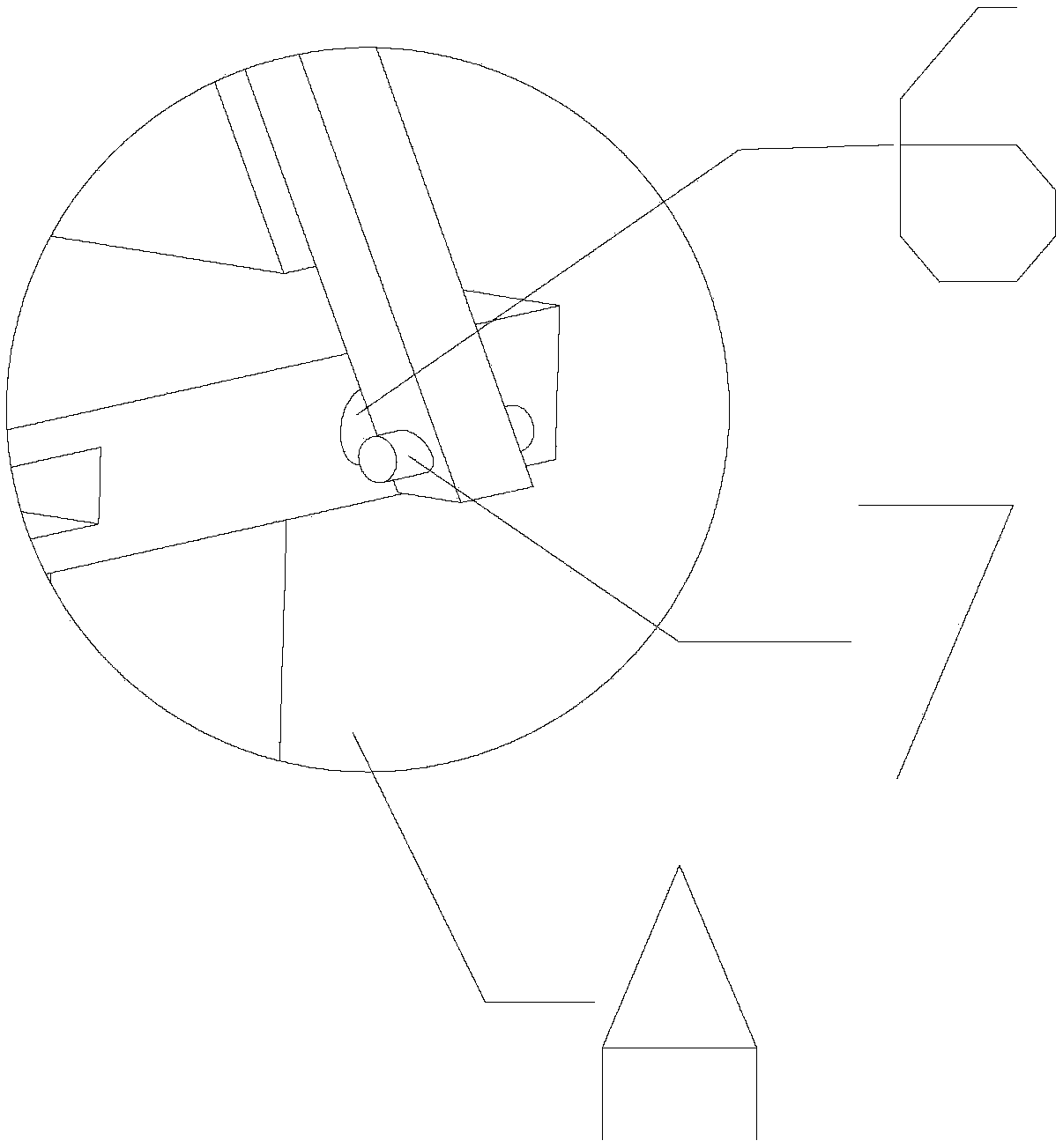

[0019] Embodiment 1: see figure 2 , the applicant added a paper tube fixing frame on the traditional cutting table, and at the same time made the original fixed cutting mechanism on the cutting table a slidable structure. After adjusting to this structure, the user When the fireworks paper tube is cut, there is no need to hold the firework paper tube by hand, so it eliminates the accidental injury of the operator when cutting the paper tube; One end of the firework paper tube can be fixed on the first fixed frame after the fixed rod is mounted. At this time, only the second fixed frame needs to be rotated. When the second fixed rod on the upper end of the second fixed frame is aligned with the first fixed rod , to swing the second fixing frame to the left, so that the second fixing rod is inserted into the other end of the fireworks tube, thereby completing the fixing process of the fireworks tube; at this time, the user only needs to grasp the first the handle on the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com