A quarter corrugated shape control method for five-stand continuous cold rolling high-strength steel strip

A five-stand cold continuous rolling, high-strength steel plate technology, applied in the direction of profile control, can solve the problems of reducing the control ability of the middle stand, increasing the pressure of the last stand to eliminate the shape defect, so as to improve the shape quality and reduce the The effect of regulating pressure and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

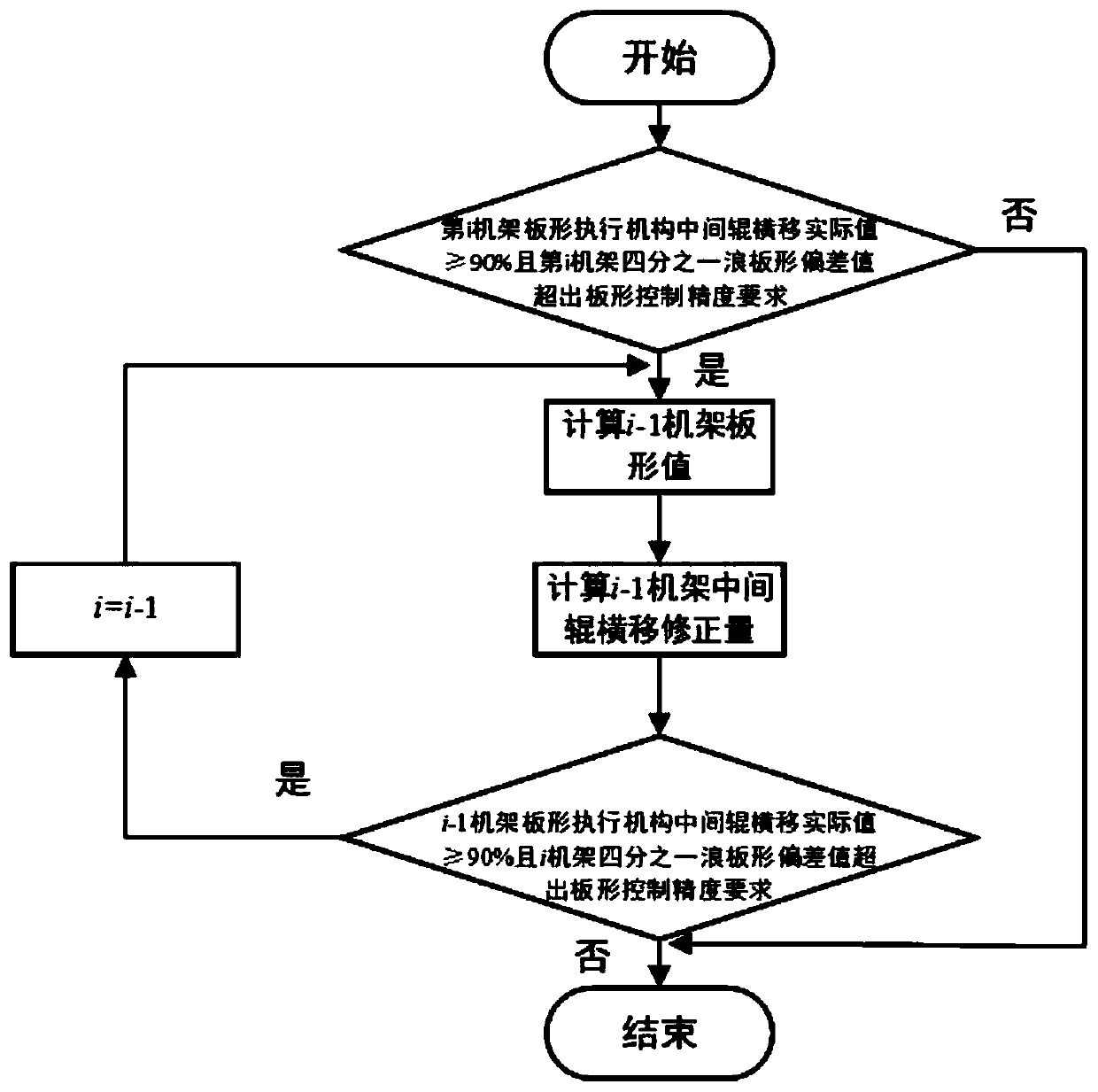

[0101] Preparation thickness is 2.75mm, and width is the QP980 automobile dual-phase steel strip of 1250mm, after five times of continuous cold rolling, be rolled into the plate strip that thickness is 0.7mm, adopt five stands cold rolling high-strength steel plate of the present invention Before and after the quarter corrugated control method of the belt is controlled, the parameters of the lateral movement of the intermediate rollers of each frame are shown in Table 1:

[0102] Table 1 The method of the present invention puts into use before and after each frame intermediate roller traverse parameter

[0103]

[0104] As can be seen from Table 1, before the method of the present invention is put into use, the intermediate roller traverse of the fifth frame has approached the limit value, while the intermediate roller traverse of the front several frames still has a margin. Figure 5 It is the shape of the finished strip before the method of the present invention is put in...

Embodiment 2

[0106] Preparation thickness is 4.0mm, and width is the DP980 automobile dual-phase steel strip of 1150mm, after five times of continuous cold rolling, be rolled into the plate strip that thickness is 1.8mm, adopt five stand cold rolling high-strength steel plates of the present invention Before and after the quarter corrugated control method of the belt is controlled, the parameters of the lateral movement of the intermediate rollers of each frame are shown in Table 2:

[0107] Table 2 The parameters of the lateral movement of the intermediate rollers of each frame before and after the method of the present invention is put into use

[0108]

[0109] As can be seen from Table 2, before the method of the present invention is put into use, the traverse of the middle roller of the fifth frame is close to the limit value, while the traverse of the intermediate rollers of several front stands still has a margin. Figure 7 It is the shape of the finished strip before the method ...

Embodiment 3

[0111] Preparation thickness is 3.0mm, and width is the DP780 automobile dual-phase steel strip of 1200mm, after five times of continuous cold rolling, be rolled into the plate strip that thickness is 0.8mm, adopt five stand cold rolling high-strength steel plates of the present invention Before and after the quarter corrugated control method of the belt is controlled, the parameters of the lateral movement of the intermediate rollers of each frame are shown in Table 3:

[0112] Table 3 The method of the present invention puts into use before and after each frame middle roller traverse parameter

[0113]

[0114] As can be seen from Table 3, before the method of the present invention is put into use, the traverse of the middle roller of the fifth frame is close to the limit value, while the traverse of the intermediate roller of the front several frames still has a margin. Figure 9 It is the shape of the finished strip before the method of the present invention is put into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com