Multifunctional fish feeder

A multi-functional, fish food technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of inability to store a variety of fish food, difficult to meet the needs of fish at different times, difficult to control the amount of fish food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

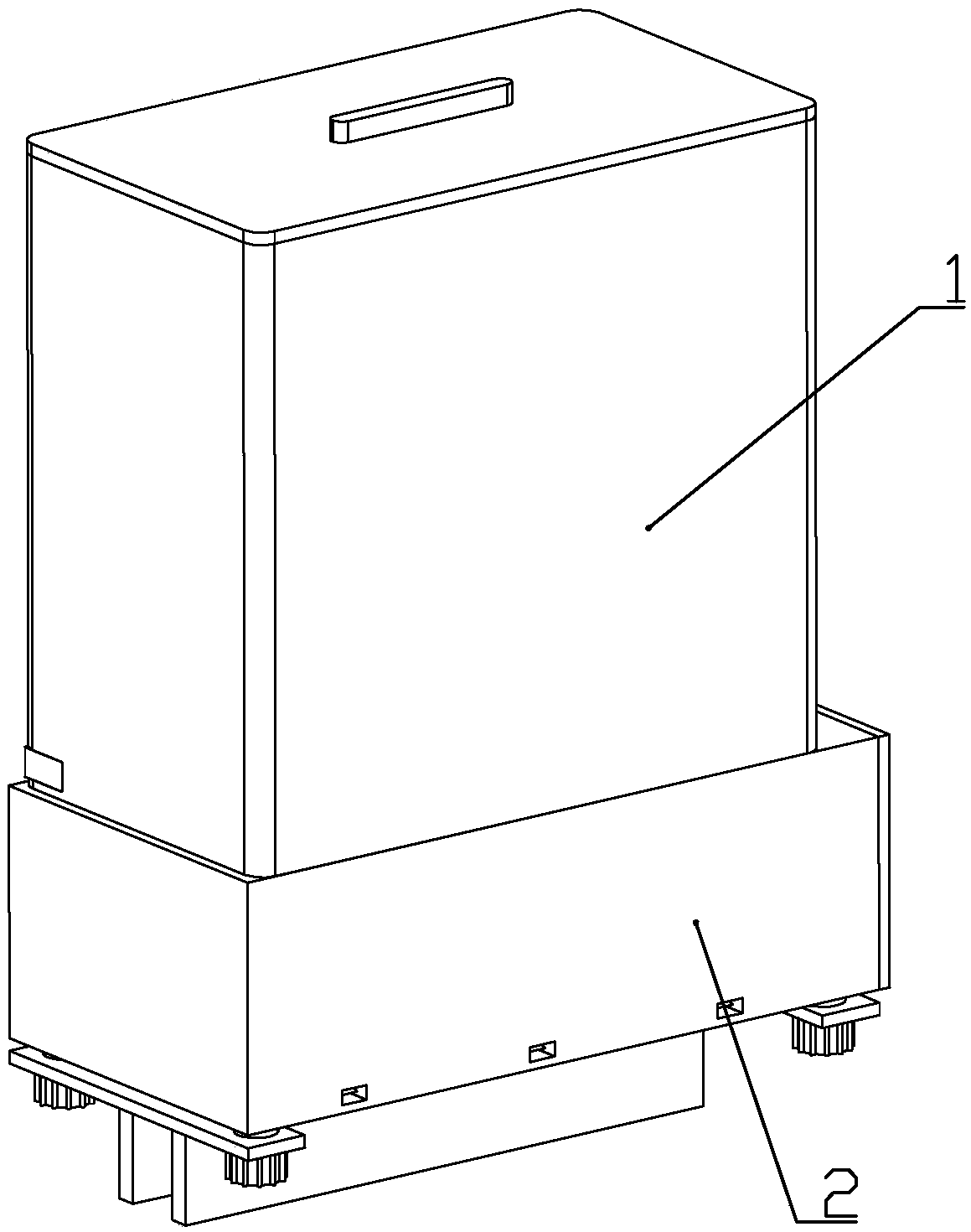

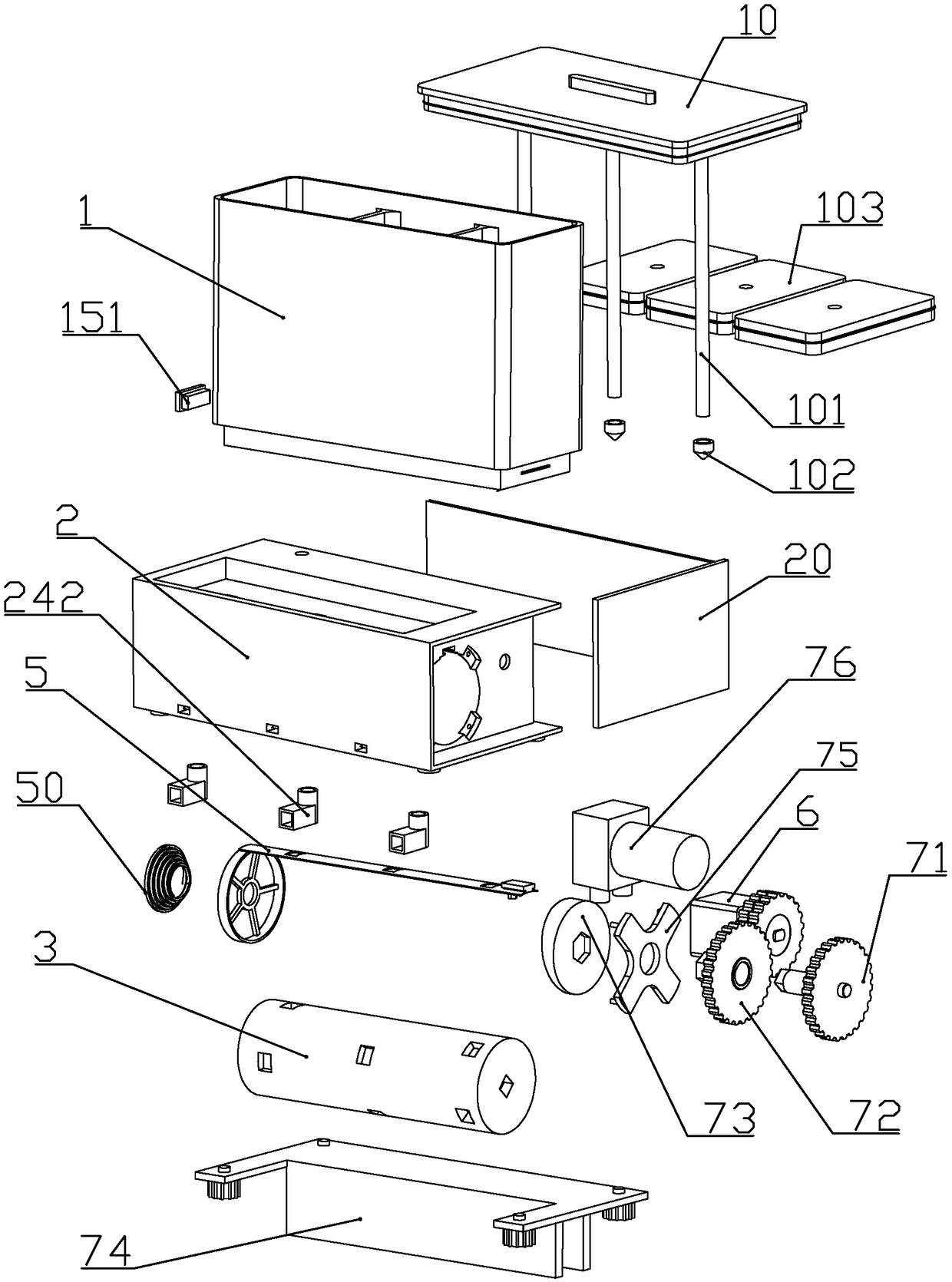

[0055] according to Figure 1 to Figure 17 As shown, a multifunctional fish feeder described in this embodiment includes a base 2, and a material box 1 installed on the upper end of the base, and a material box cover 10 is detachably connected to the material box; A plurality of storage cavities 11 for storing fish food are formed in the box; different types of granular feed can be stored in each storage cavity, so as to provide different types of nutrition for fish.

[0056] The front part of the base is a rotating column installation groove 22 with the axis along the horizontal direction; the side of the rotating column installation groove on the base is a gear installation groove 23, and the rear end of the rotating column installation groove on the base is a motor installation Slot 24.

[0057] The lower end of each storage cavity is formed with a drop tube 13 communicating with the top of the rotating column installation groove.

[0058] The section of the inner bottom ...

Embodiment 2

[0117] according to Figure 17 to Figure 20 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: the lower end of the base is equipped with a foam shell 81 whose lower part extends below the water surface of the fish tank; The foam material tank 813, the foam material connecting plate 811 formed on the upper end of the foam material tank and fixedly connected with the base frame, and the piston sliding groove 812 located on one side of the foam material tank.

[0118] A piston 82 driven by an air pump is connected in sealing and sliding connection in the sliding groove of the piston; a piston spring 83 capable of driving the piston to move upward is installed between the bottom of the sliding groove of the piston and the piston.

[0119] The upper part of the side wall of the sliding groove of the piston is formed with an air outlet 8121 connecting the sliding groove of the piston with the outside world; the diameter of the air outlet is sma...

Embodiment 3

[0133] This embodiment makes the following improvements on the basis of the foregoing embodiments: the upper ends of the valve plates are fixedly connected with sealing gaskets on one side of each material port; The material openings are sealed against each other, so that the material storage chamber is in a closed environment.

[0134] When the controller controls the air pump to pump air in the storage chamber, the storage chamber can be evacuated, so that fish food can be stored better.

[0135] With the operation of the air pump, the air pressure in the material storage chamber decreases, so that the sealing piston moves downward, and always touches the upper end of the fish food. When performing the next air pumping work, it is only necessary to pump out the air below the sealing piston in the material storage chamber. That is, the extraction amount of air is reduced, and the workload of the air pump is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com