Multi-layer hog house

A multi-layer pig house, rectangular technology, applied in the field of pig raising equipment, can solve the problems of low efficiency, a lot of manpower and high cost, and achieve the effects of reducing production costs, improving production efficiency and ingredient quality, and being easy to discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

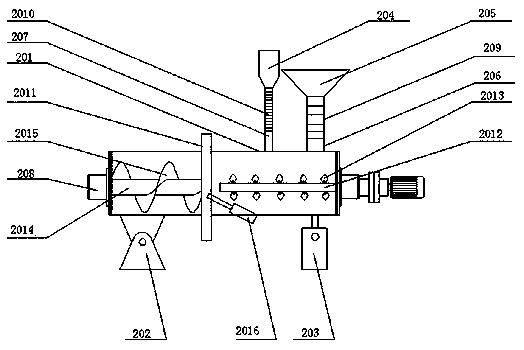

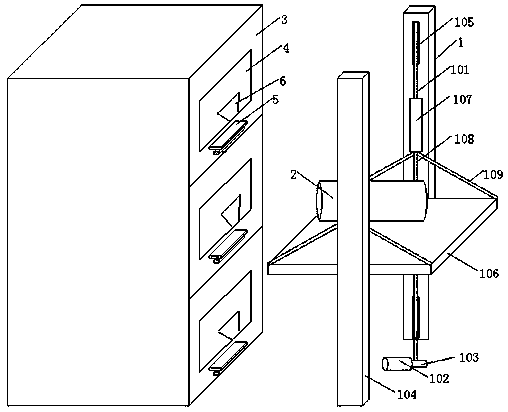

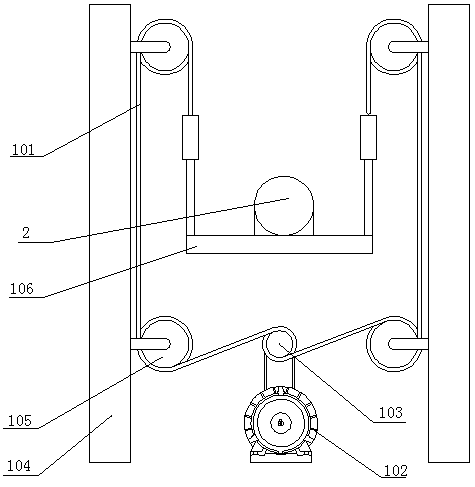

[0022] Such as Figure 1 to Figure 7 As shown, a multi-storey pig house includes a plurality of feeding rooms 3 arranged sequentially from top to bottom, one side of the feeding room 3 is provided with a transport mechanism 1, and the side wall of the feeding room 11 close to the transport mechanism is provided with a transport port 4. A feed trough 6 is arranged in the feeding room 3 , and one end of the feed trough 6 is set close to the transport port 4 .

[0023] The transport mechanism 1 comprises a steel wire rope 101, a motor 102, an output shaft 103 of a reducer connected to the motor 102, two vertical columns 104 arranged in parallel at intervals, and a rectangular object platform 106 arranged between the two vertical columns 104. A connecting rod 107 is arranged on the top of the two ends of the two upright columns 104 close to the object platform 106, and a vertical rod 108 and two inclined rods 109 are arranged below each connecting rod 107. The vertical rod 108 and...

Embodiment 2

[0036] Such as Figure 1 to Figure 7 As shown, a multi-storey pig house includes a plurality of feeding rooms 3 arranged sequentially from top to bottom, one side of the feeding room 3 is provided with a transport mechanism 1, and the side wall of the feeding room 11 close to the transport mechanism is provided with a transport port 4. A feed trough 6 is arranged in the feeding room 3 , and one end of the feed trough 6 is set close to the transport port 4 .

[0037] The transport mechanism 1 comprises a steel wire rope 101, a motor 102, an output shaft 103 of a reducer connected to the motor 102, two vertical columns 104 arranged in parallel at intervals, and a rectangular object platform 106 arranged between the two vertical columns 104. A connecting rod 107 is arranged on the top of the two ends of the two upright columns 104 close to the object platform 106, and a vertical rod 108 and two inclined rods 109 are arranged below each connecting rod 107. The vertical rod 108 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com