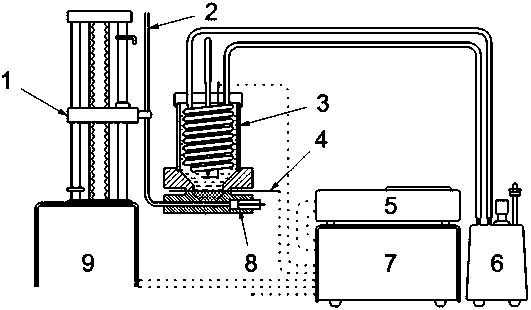

Enamel steel fish-scaling performance drainage hydrogen measurement experimental detection device and detection method

A detection device and a technology for enamel steel, applied in the direction of electrochemical variables of materials, etc., can solve the problem of failing to provide the anti-scaling performance of cold-rolled steel plates for enamel, and achieve the effects of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

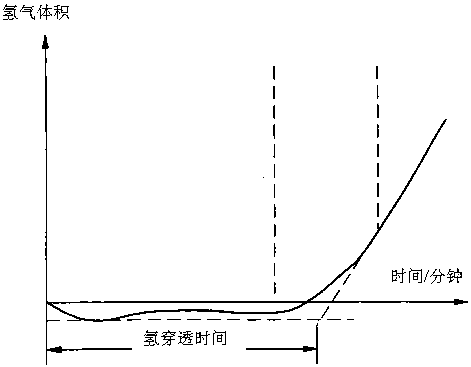

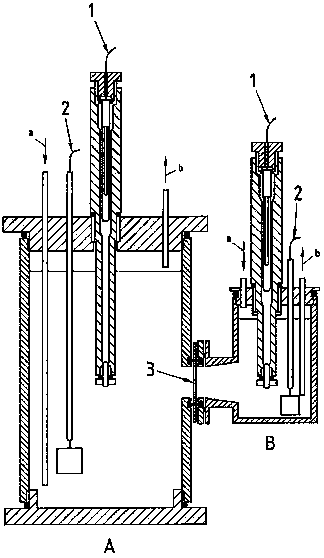

[0055] The hydrogen penetration curve of the enamel steel plate can be measured by adopting the experimental detection device of the present invention, so as to characterize its anti-scale explosion performance. The test process complies with the BS EN 10209-2013 standard, as follows.

[0056] 1. Sample

[0057] At least 4 parallel samples of each material. The sample size is 70-90mm wide and not less than 100mm in length. It should be noted that the edge of the steel coil has a higher sensitivity to scale explosion than the center.

[0058] 2. Experiment preparation

[0059] Step 1: Degrease

[0060] 30±5g / l degreaser in distilled water. The solution was held in a glass container and changed daily. The degreasing temperature is 70-75°C, the degreasing time is 5 minutes, and electromagnetic stirring is performed during the degreasing process.

[0061] Step 2: Rinse in cold water

[0062] Rinse (or soak) in tap water for 30 seconds.

[0063] Step 3: Degrease

[0064] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com