Pipe bundling and bagging machine

A technology of bagging machine and bundling mechanism, which is applied to the parts of bundling machinery, packaging/bundling items, external support, etc., can solve the problems of slow development, low efficiency and long packaging time of pipe packaging technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0158] The present invention will be further described below with reference to the accompanying drawings and embodiments.

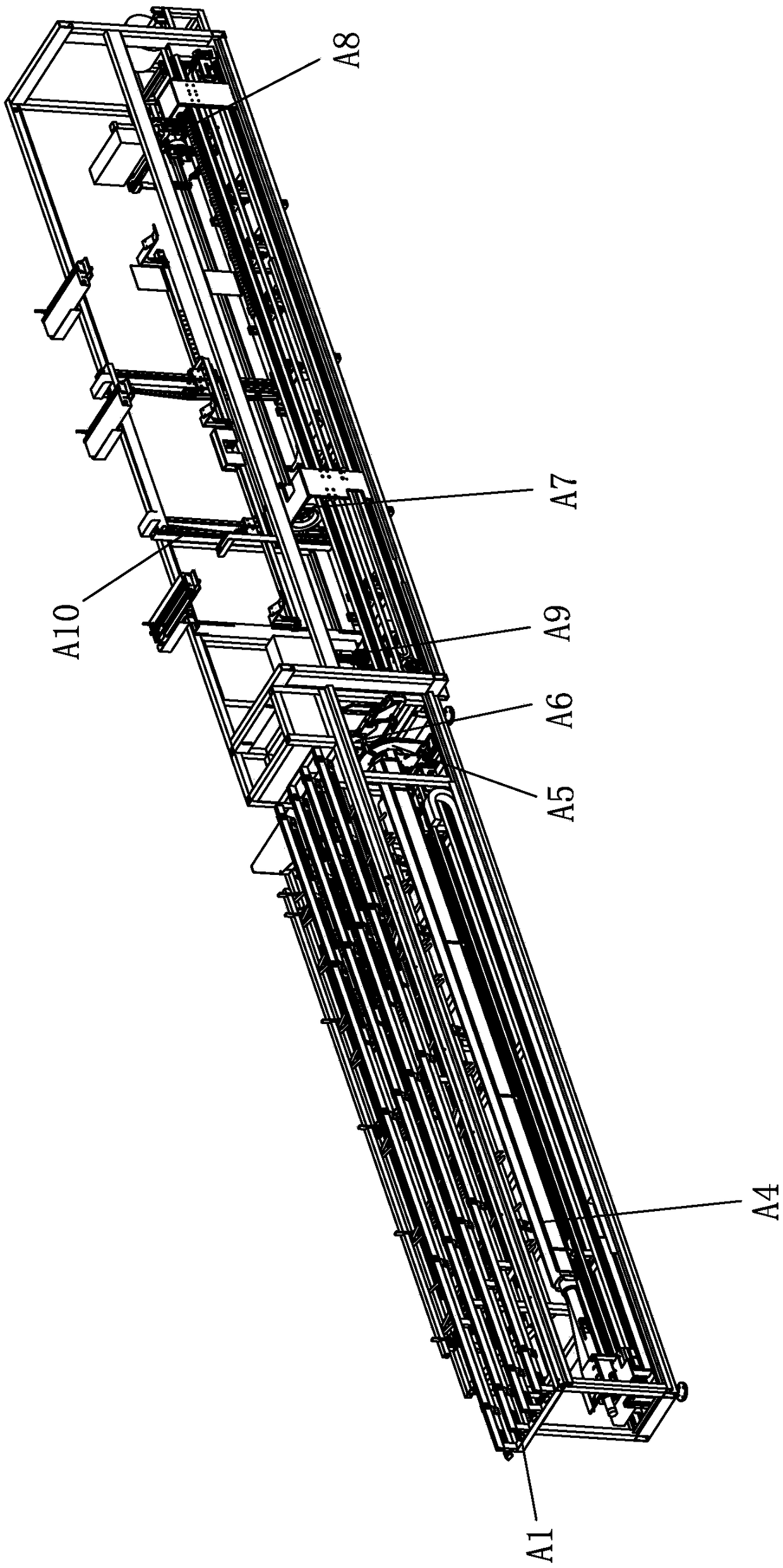

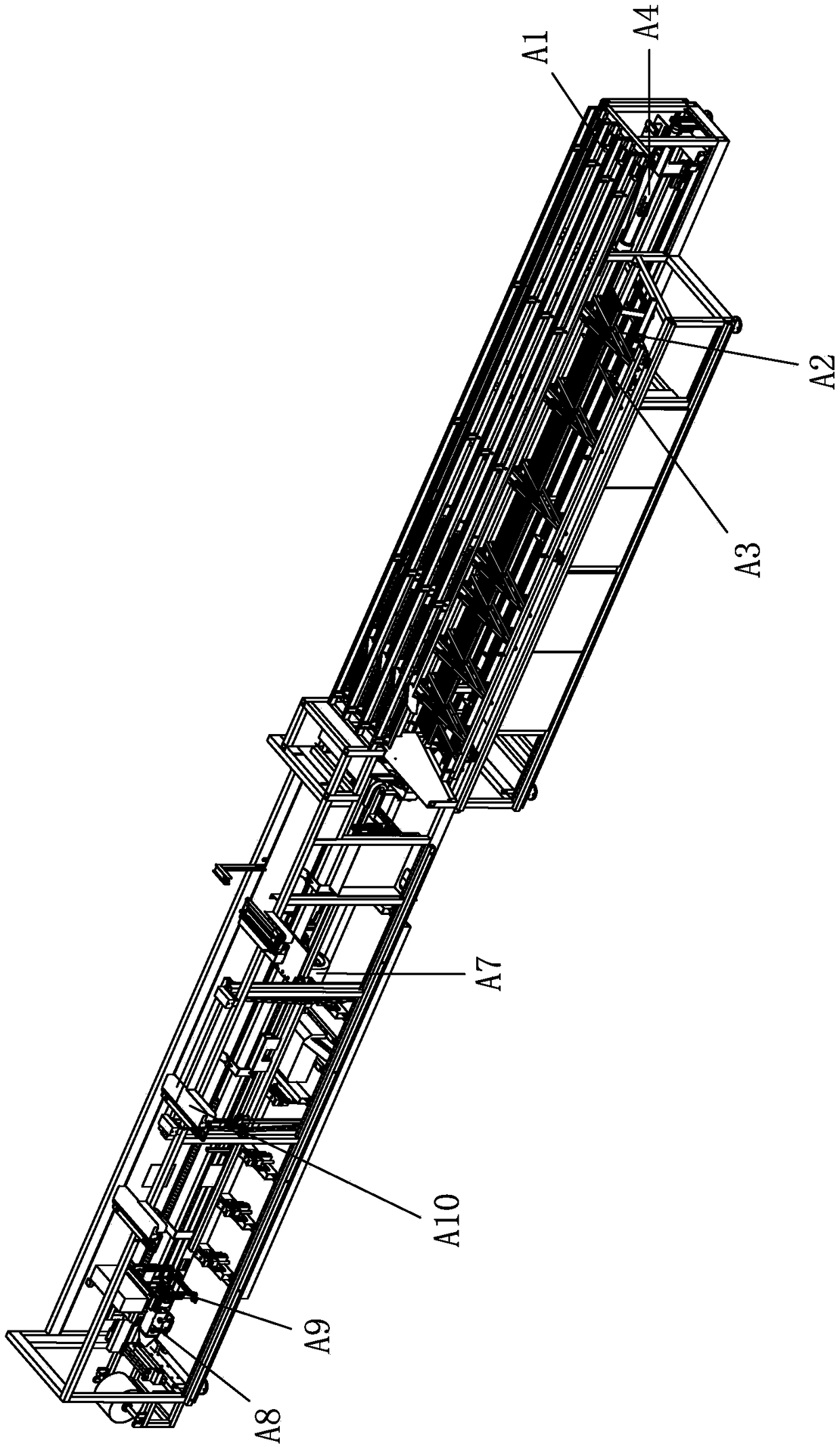

[0159] see Figure 1-Figure 53 , the pipe binding and bagging machine includes a main frame, a turning structure A1, a material guiding device A2, a material pushing device A4, a film binding mechanism, a bagging and packaging mechanism and an unloading device A10 all arranged on the main frame;

[0160] The material turning structure A1 is set above the material guiding device A2, the material pushing device A4, the film binding mechanism and the bagging and packaging mechanism are arranged in sequence from left to right, the material guiding device A2 is located on the side of the material pushing device A4, and the unloading device A10 is located on the side of the material pushing device A4. the sides of the bagging mechanism;

[0161] The material turning structure A1 is used to introduce the external pipe material 90 to be bundled into the bag and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap