A high-efficiency reactor for accelerating heat dissipation

A technology of heat dissipation rate and reaction kettle, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

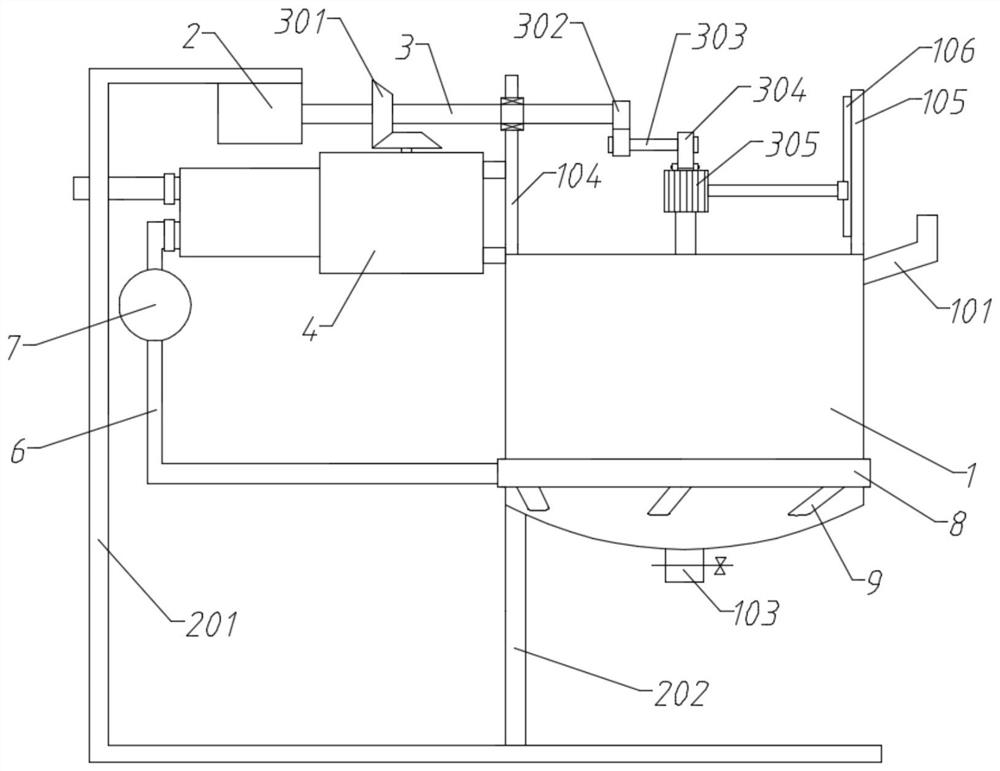

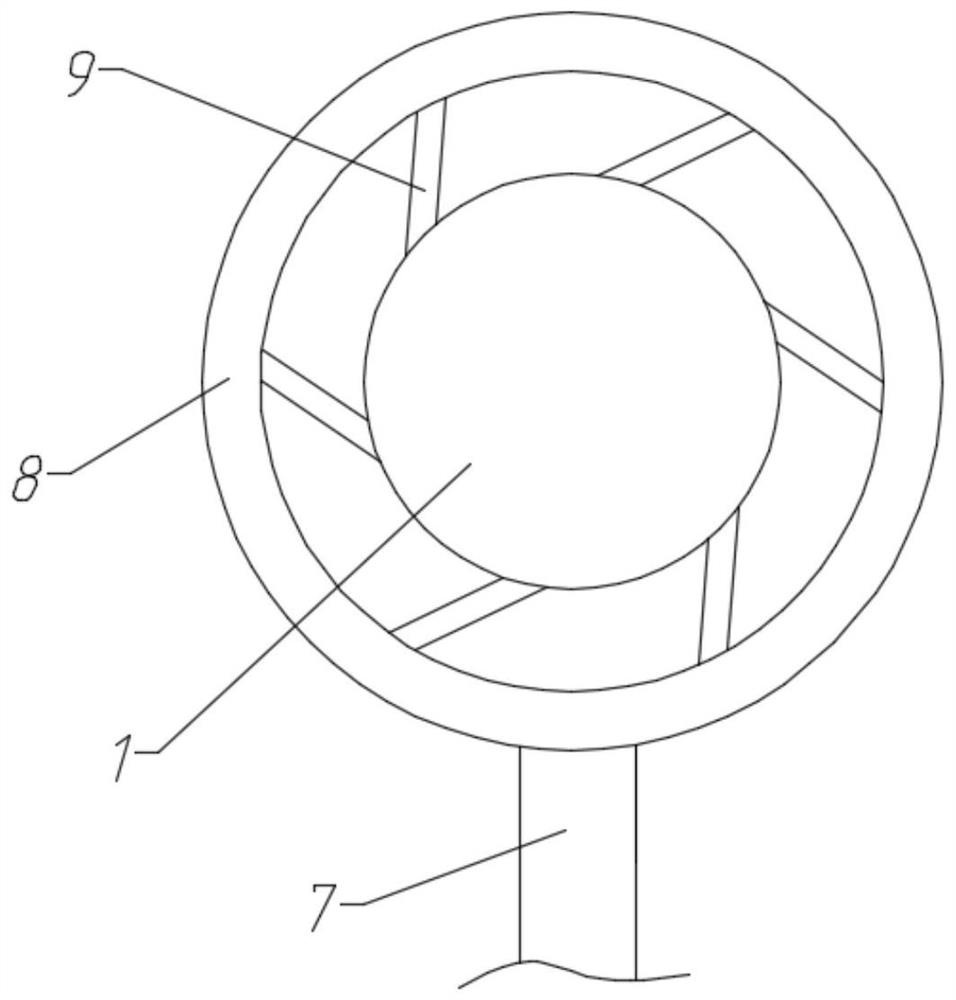

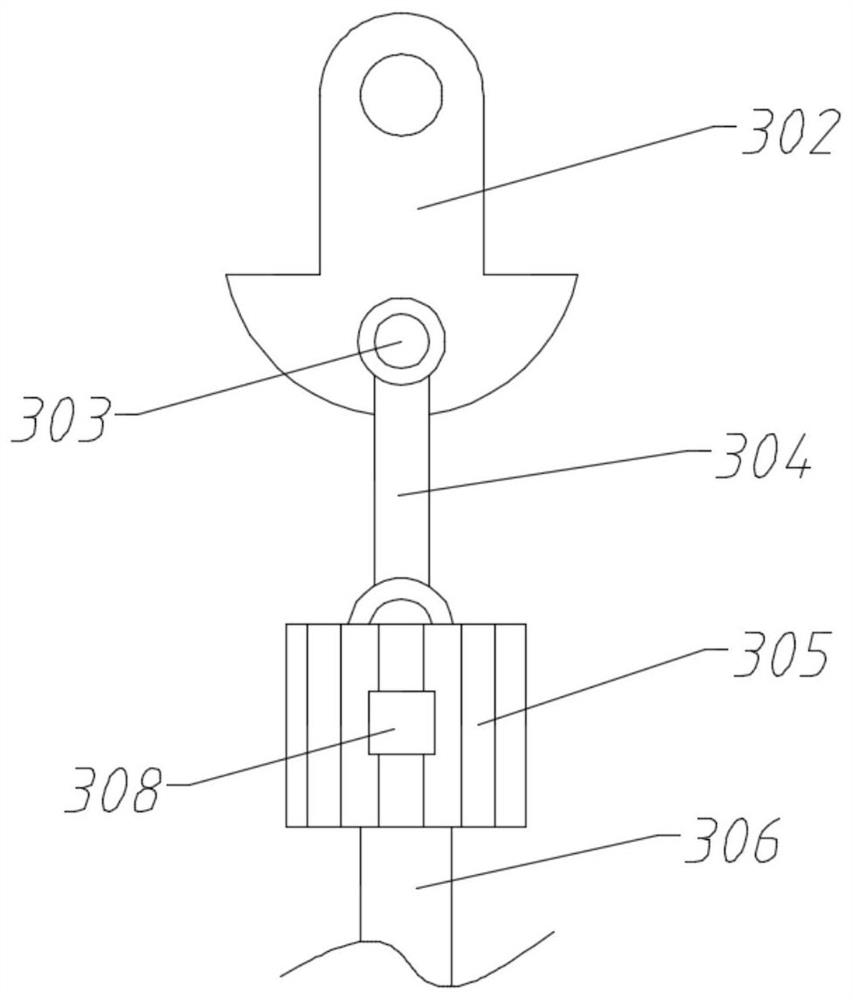

[0041] A high-efficiency reaction kettle for accelerating heat dissipation, including a tank body 1, a mounting frame 201, a lifting component and a suction structure 4;

[0042] The mounting frame 201 is a similar C-shaped plate bent up and down, and the upper end is bent shorter than the lower end; the tank body 1 is arranged on the left side of the mounting frame 201, and the left end of the bottom of the tank body 1 is fixedly connected to the lower end of the mounting frame 201 through a support rod 202; The drive motor 2 is installed on the upper end of the frame 201, and the output end of the drive motor 2 stretches out horizontally to the right and is connected with the driving shaft 3, which is arranged higher than the tank body 1;

[0043] A liquid inlet pipe 101 is connected to the top of one side of the tank body 1; a vertical left support plate 104 and a right support plate 105 are fixedly connected to the left and right ends of the top of the tank body 1; The rig...

Embodiment 2

[0054] A high-efficiency reaction kettle for accelerating heat dissipation, including a tank body 1, a mounting frame 201, a lifting component and a suction structure 4;

[0055] The mounting frame 201 is a similar C-shaped plate bent up and down, and the upper end is bent shorter than the lower end; the tank body 1 is arranged on the left side of the mounting frame 201, and the left end of the bottom of the tank body 1 is fixedly connected to the lower end of the mounting frame 201 through a support rod 202; The drive motor 2 is installed on the upper end of the frame 201, and the output end of the drive motor 2 stretches out horizontally to the right and is connected with the driving shaft 3, which is arranged higher than the tank body 1;

[0056] A liquid inlet pipe 101 is connected to the top of one side of the tank body 1; a vertical left support plate 104 and a right support plate 105 are fixedly connected to the left and right ends of the top of the tank body 1; The rig...

Embodiment 3

[0065] A high-efficiency reaction kettle for accelerating heat dissipation, including a tank body 1, a mounting frame 201, a lifting component and a suction structure 4;

[0066] The mounting frame 201 is a similar C-shaped plate bent up and down, and the upper end is bent shorter than the lower end; the tank body 1 is arranged on the left side of the mounting frame 201, and the left end of the bottom of the tank body 1 is fixedly connected to the lower end of the mounting frame 201 through a support rod 202; The drive motor 2 is installed on the upper end of the frame 201, and the output end of the drive motor 2 stretches out horizontally to the right and is connected with the driving shaft 3, which is arranged higher than the tank body 1;

[0067] A liquid inlet pipe 101 is connected to the top of one side of the tank body 1; a vertical left support plate 104 and a right support plate 105 are fixedly connected to the left and right ends of the top of the tank body 1; The rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com