Washability evaluation method in coal dressing process by using sound recognition method

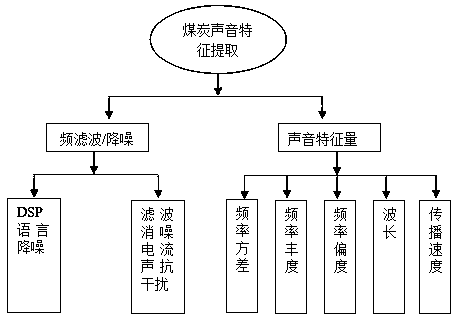

A sound recognition and optional technology, applied in the direction of using sonic/ultrasonic/infrasound to analyze solids, material inspection articles, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

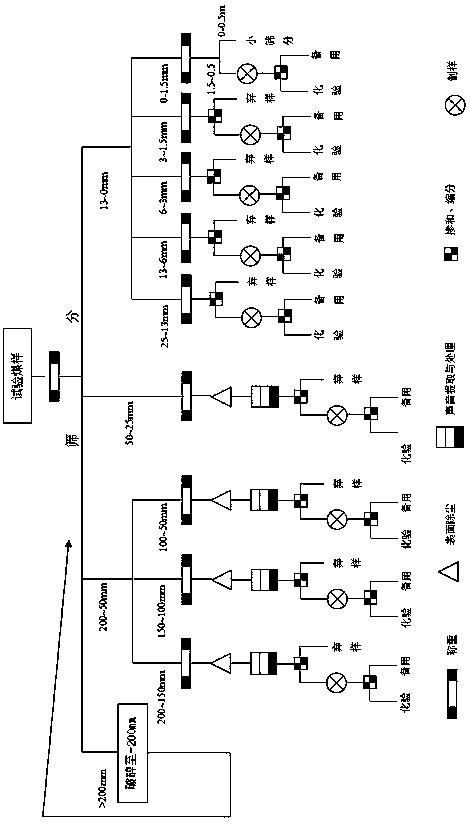

[0025] Such as figure 1 As shown, the selectivity assessment method in the coal preparation process of a kind of sound recognition method of the present embodiment comprises the following steps:

[0026] S1. Raw coal sample collection: collect raw coal samples on the underground raw coal belt or the belt under the raw coal bunker, the sampling volume is ≥ 10 tons, the sampling time is ≥ 8 hours, and the number of sub-samples is ≥ 30;

[0027] S2. Raw coal sample analysis: including elemental analysis, industrial analysis, coal ash composition analysis, and physical property analysis of raw coal samples; elemental analysis includes analysis of carbon, hydrogen, oxygen, nitrogen, sulfur, and phosphorus element content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com