Tile sizing machine

A technology for a sizing machine and ceramic tiles, which is applied to the field of auxiliary machinery and equipment for building decoration, can solve the problems of unreliable sizing quality, easy fatigue of workers, low labor efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

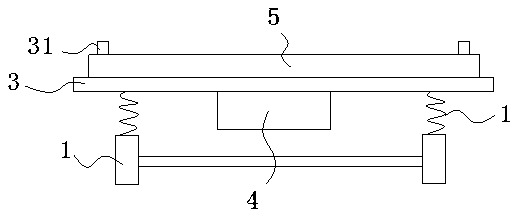

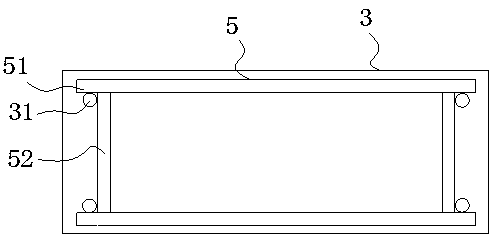

[0009] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed instructions.

[0010] like figure 1 , 2 , The ceramic tile sizing machine of the present invention includes a support stand 1, the upper end of the support stand 1 is connected with a vibration plate 3 through a spring 2, a vibration motor 4 is provided on the bottom surface of the vibration plate 3, and a movable plate is provided on the top surface of the vibration plate 3. The slurry mold frame 5, the movable slurry mold frame 5 is a square frame, and the movable slurry mold frame 5 is vertically movably fixed on the top surface of the vibration plate 3.

[0011] When the present invention is in use, the movable slurry mold frame 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com