Powder type feeding device

A technology of feeding device and powder, applied in the field of mechanical conveying, can solve the problems of high labor intensity, dust phenomenon and serious problems of workers, and achieve the effect of slowing down dust phenomenon, reducing labor intensity and reducing dust phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

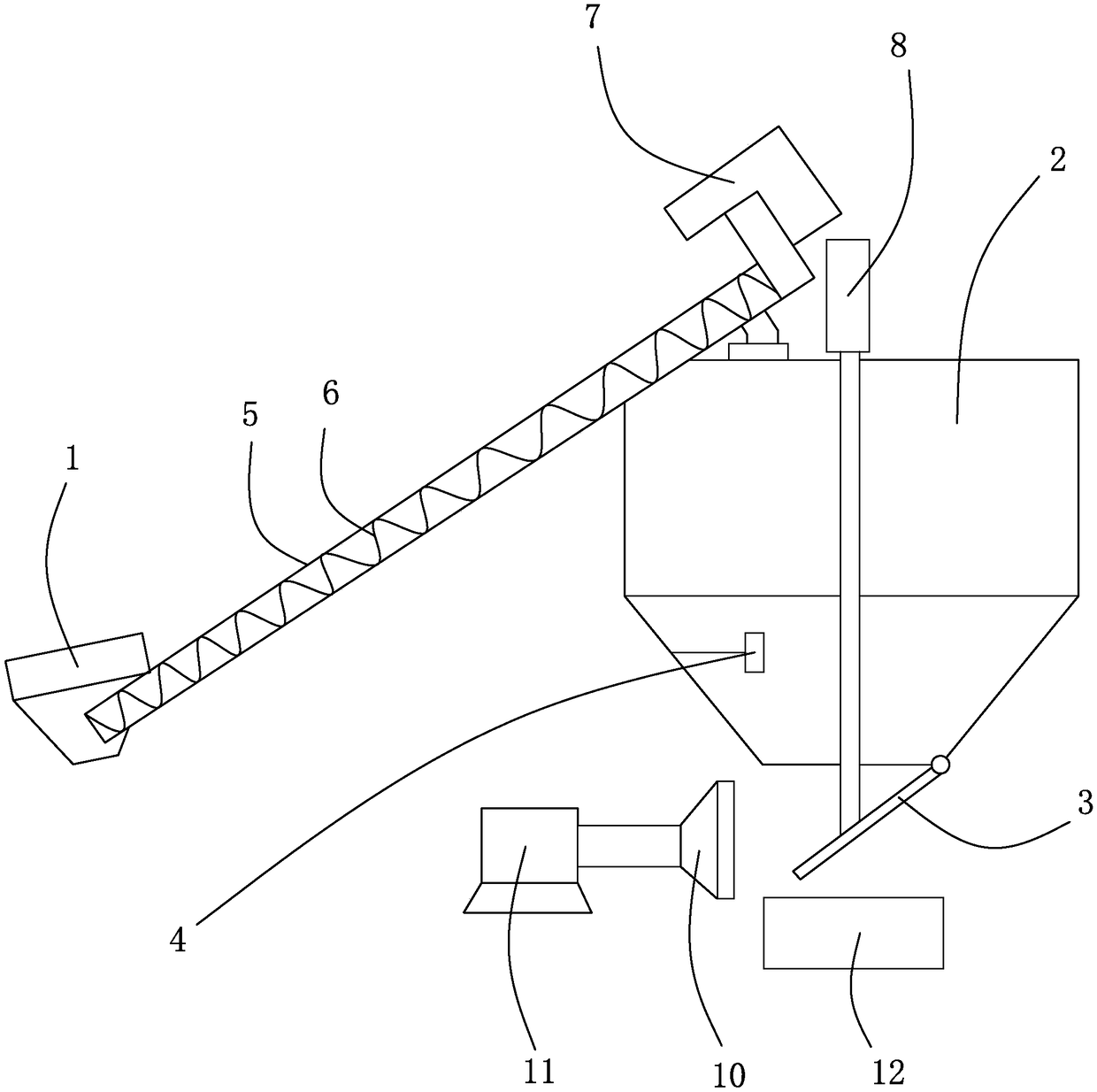

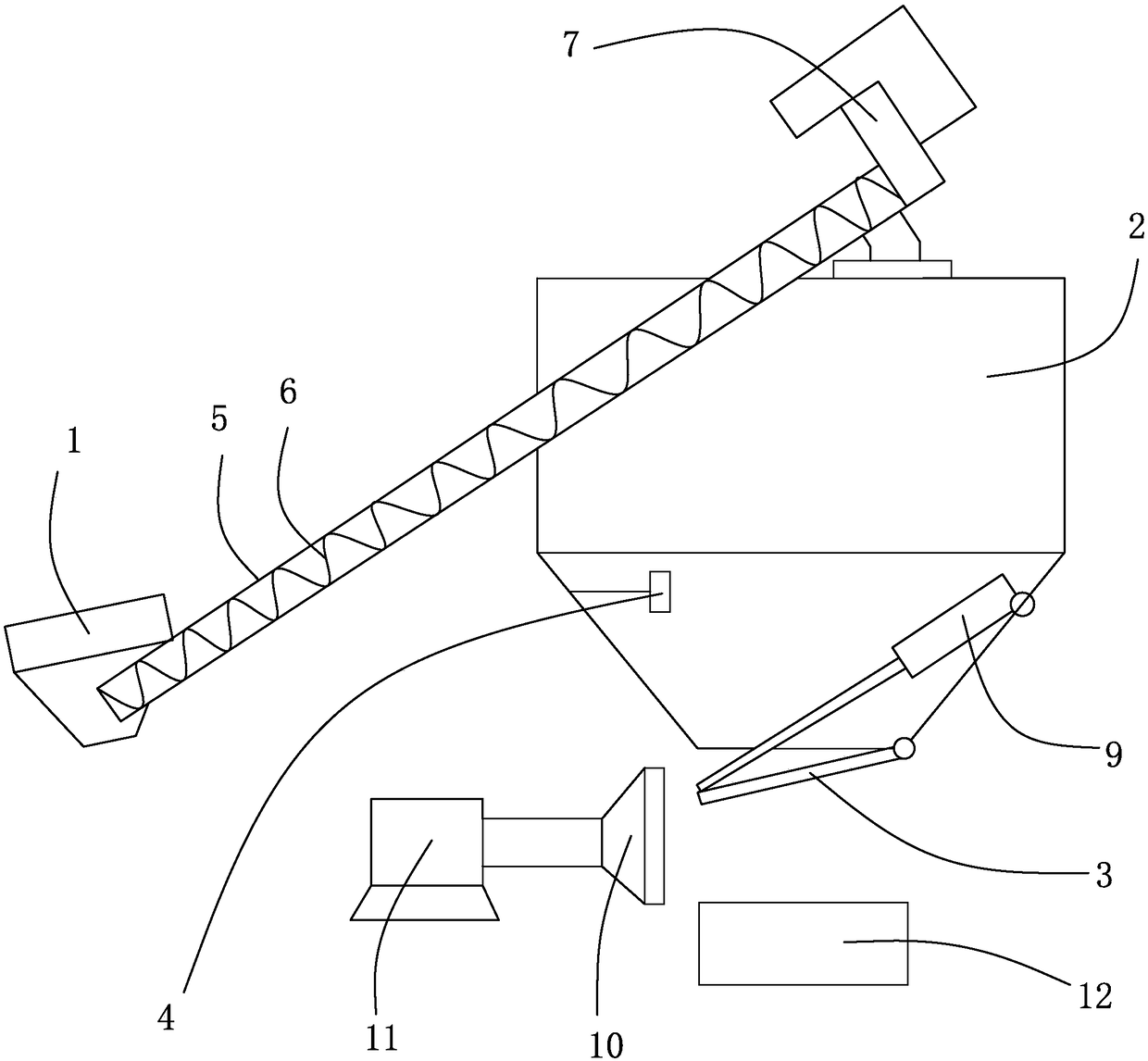

[0016] like figure 1 , figure 2 As shown, a powder feeding device provided by the present invention includes a hopper 1, a screw conveying mechanism, a silo 2 and a control unit. The hopper 1 is arranged at the front end of the silo 2, and the material is conveyed by the screw conveying mechanism. In the silo 2, the bottom of the silo 2 is provided with a discharge port, and one end of the discharge port is hinged with a door 3, and the silo 2 is provided with an opening mechanism for the door 3, and the opening mechanism for the door 3 is used to control the opening of the door 3. , together, the material level sensor 4 is arranged inside the hopper 2, and the material level sensor 4 transmits a signal to the control unit, and the control unit controls the work of the opening mechanism of the silo door 3, and a dust removal mechanism is arranged on one side of the discharge port. Further improvement, the screw conveying mechanism includes a screw barrel 5 and a feed screw 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com