Automatic batching system for laboratory

A technology for automatic batching and laboratory use, which is applied to mixer accessories, mixers, conveyors, etc., and can solve problems such as difficult operation, inconvenient operation, and human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

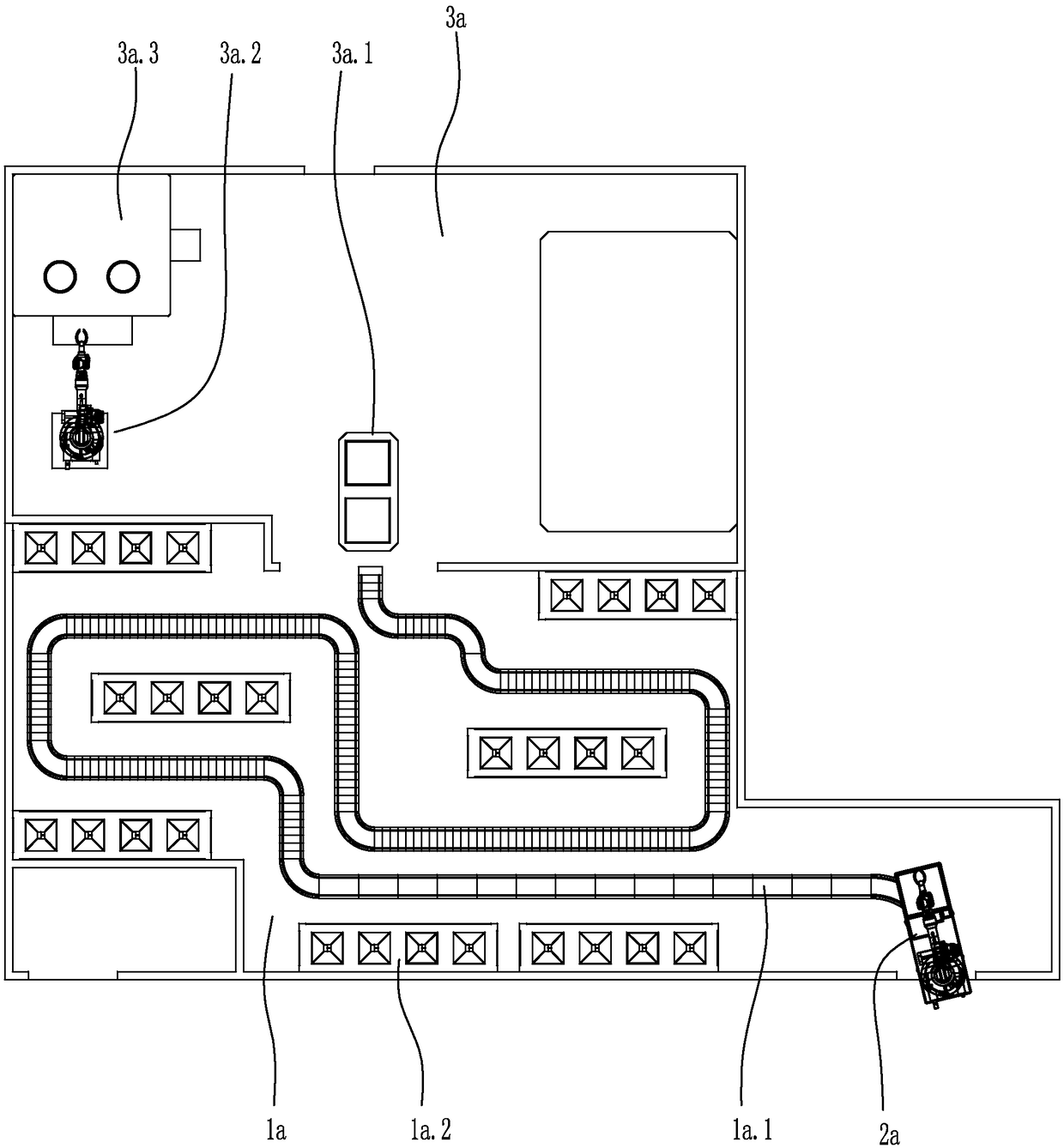

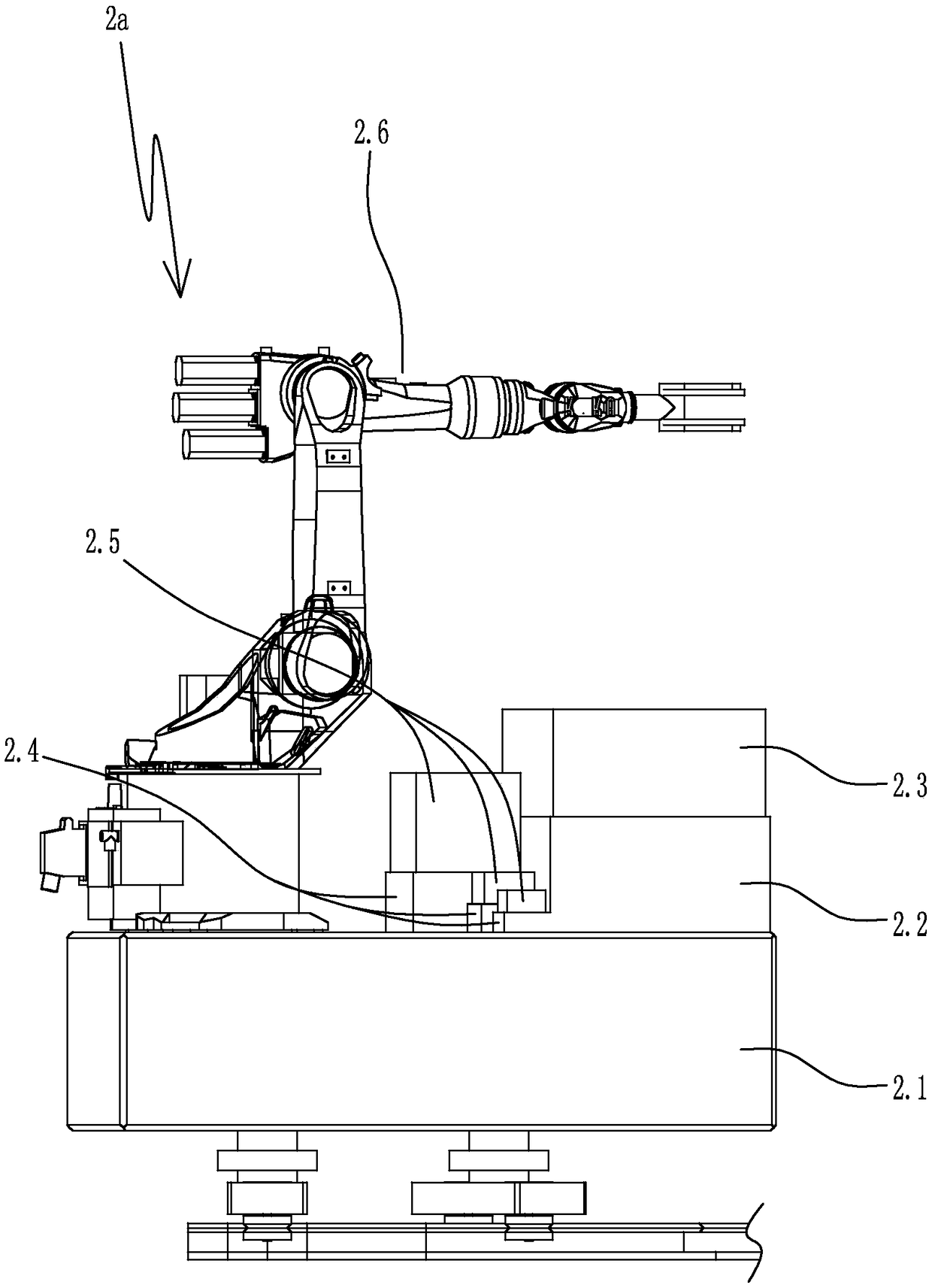

[0038] Specific embodiment one: as figure 1 As shown, an automatic batching system for laboratory use is characterized by a material storage area 1a, a material distribution trolley 2a and a batching area 3a.

[0039] The material storage area is provided with a running track 1a.1 and a number of material storage racks 1a.2 arranged along the running track. The material storage area has a storage area entrance and a storage area exit connected to the batching area. The walking track is zigzag arranged in the material storage area. One end of the walking track is close to the entrance of the storage area, and the other end of the walking track is close to the exit of the storage area.

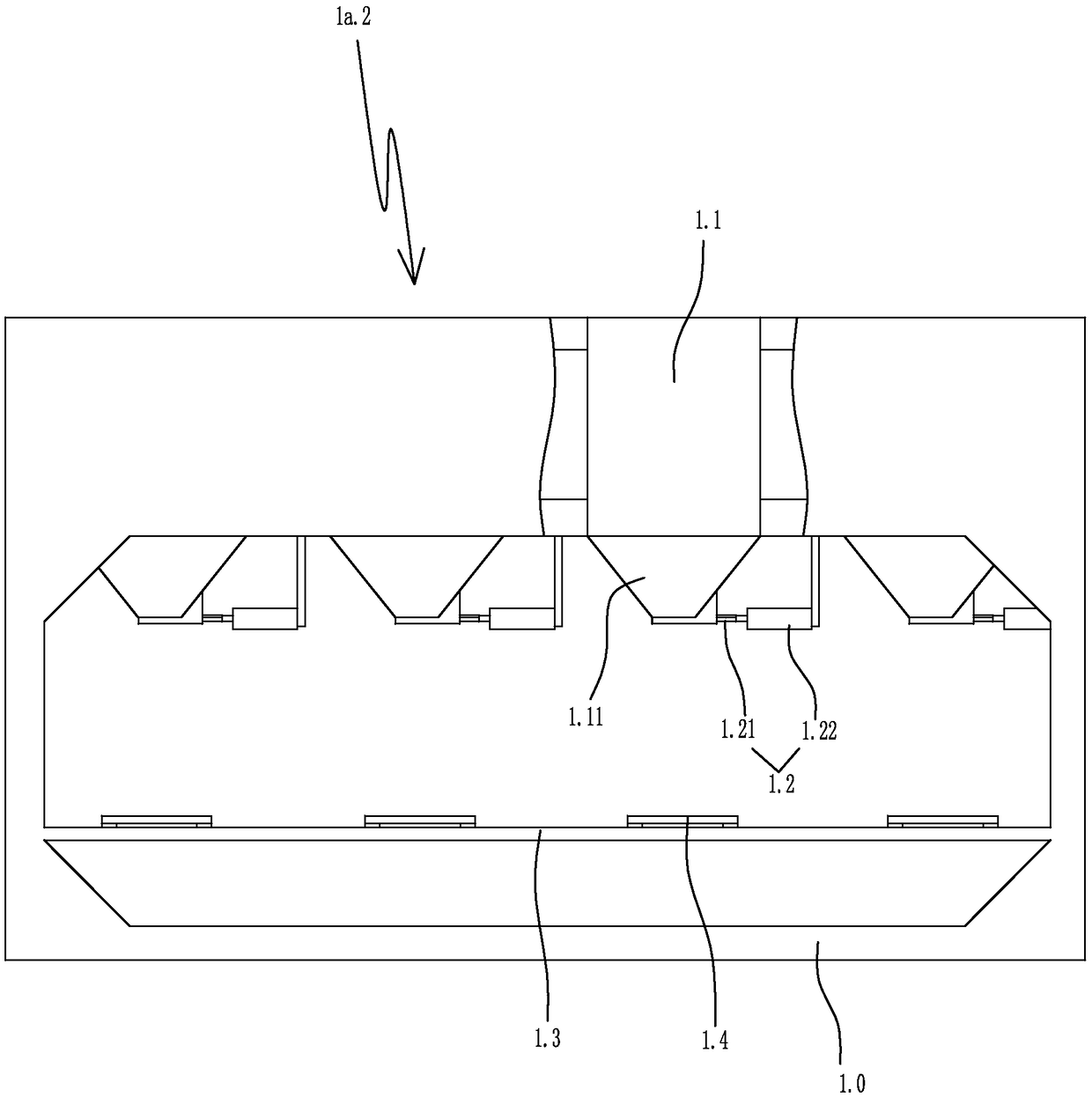

[0040] Such as figure 2 As shown, the material storage rack 1a.2 is arranged near the running track. The material storage rack includes a material rack 1.0, a number of storage hoppers 1.1 arranged on the material rack, a support plate 1.3 located below the storage hopper, and a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com