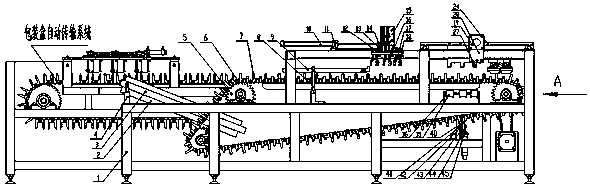

Lamp loading machine of LED integrated lamp packaging line

A technology for packaging lines and lamps, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve problems such as large losses, high number of workers, and increased production costs, and achieve efficient and safe packaging, saving manpower. The effect of resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

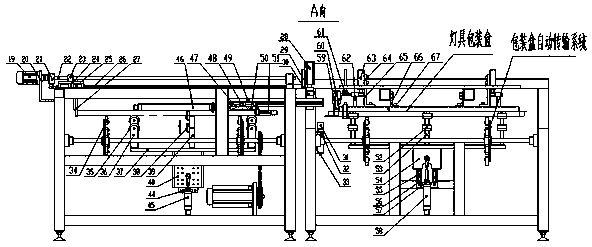

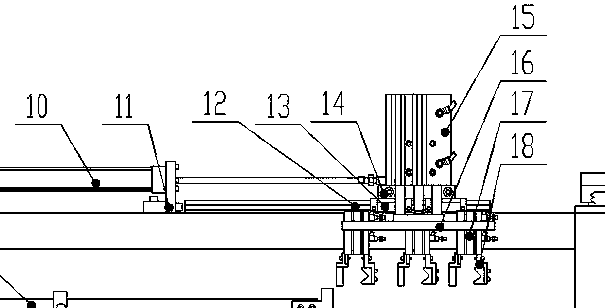

[0014] LED integrated lamp packaging line lamp loading machine, the frame (1) is equipped with a lamp automatic loading bin side plate (2), and the lamp automatic feeding bin side plate (2) is equipped with a lamp automatic feeding bin guide rail (3), a fixed bracket (4) is welded on the top of the frame (1), a transmission wheel (5) is arranged on the frame, a transmission chain (6) is embedded on the transmission wheel (5), and the transmission chain ( 6) is provided with a lamp holder (7), a fixed frame (8) is welded on the frame, and a detection and rejection material rack (9) is arranged on the fixed frame (8), and the detection and rejection material rack (9) ) is provided with a fixed plate two (16), an upward and downward movement control cylinder (15) is arranged at the upper end of the fixed plate two (16), and a detecting and rejecting manipulator control cylinder ( 17), a detecting and rejecting manipulator (18) is provided at the lower end of the detecting and rej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com