Hydroponic pot, column and cultivation device

A cultivation device and pot technology, which is applied in the field of soilless cultivation, and can solve the problems such as the easy lack of oxygen in the root system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

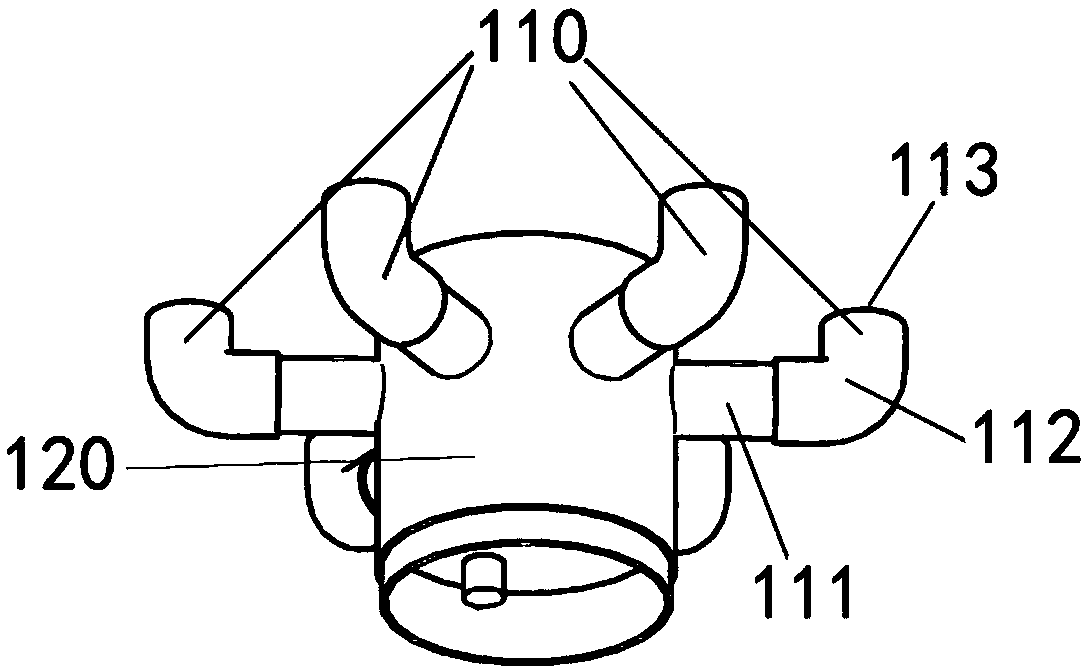

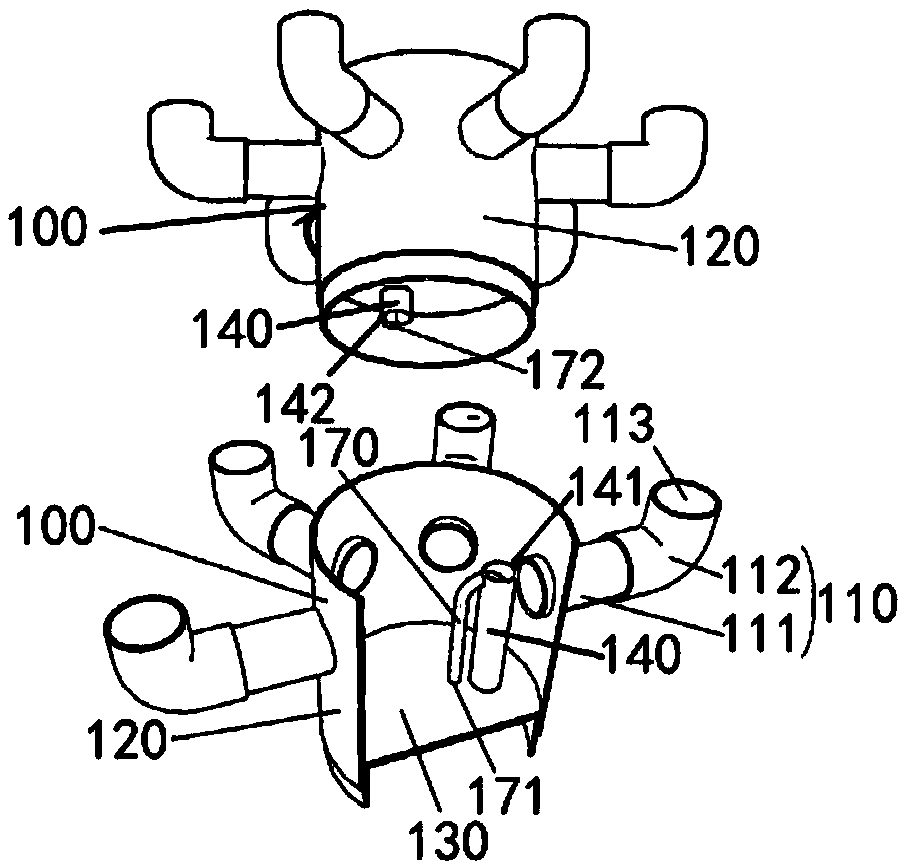

[0032] See figure 1 , figure 1 It shows the top view and bottom view structure diagrams of the hydroponic basin provided by the embodiment of the present application. The present application provides a hydroponic pot 100, the hydroponic pot 100 includes: a side wall 120, a bottom plate 130, an overflow pipe 140 and at least one cultivation pipe 110; the side wall 120 forms a pot around the bottom plate 130, and the bottom plate 130 An overflow pipe 140 is arranged on the top, the overflow pipe 140 runs through the bottom plate 130, the bottom plate 130 is seamlessly connected with the outside of the overflow pipe 140, at least one cultivation pipe 110 is arranged on the side wall 120, the side wall 120 and at least one cultivation pipe 110 The outside is seamlessly connected, and the pelvic cavity, the overflow pipe 140 and the cultivation pipe 110 are all connected.

[0033] Wherein, it should be noted that the hydroponic pot 100 includes: a side wall 120, a bottom plate 13...

no. 2 example

[0049] See Figure 4 , Figure 4 A schematic diagram of the column structure provided by the embodiment of the present application is shown. The application provides a column 101. The column 101 includes: a base 200 and at least one hydroponic pot 100 as above; Flexible connection; at least one drain hole 210 is provided on the side of the base 200 , and at least one hydroponic pot 100 , the base 200 and at least one drain hole 210 are connected in sequence.

[0050] Among them, it should be noted that the column 101 includes: a base 200 and at least one hydroponic pot 100 as above; at least one hydroponic pot 100 is connected in turn, and the base 200 is movably connected with at least one end of the hydroponic pot 100 near the ground; At least one drain hole 210 is provided on the side of the base 200 , and the at least one hydroponic pot 100 , the base 200 and the at least one drain hole 210 are connected in sequence. The base has the same internal and external diameter ...

no. 3 example

[0087] See Image 6 , Image 6 A schematic structural diagram of the cultivation device provided by the embodiment of the present application is shown. A kind of cultivating device 107 that the present application provides, and cultivating device 107 comprises: cultivating tank 102, return pipe 103, liquid reservoir 104 and a plurality of as above column 101; One end of the return pipe 103 is movably connected with the cultivation tank 102, and the end of the return pipe 103 away from the cultivation tank 102 is movably connected with the liquid storage tank 104, and the liquid storage tank 104 is communicated with the cultivation tank 102 through the return pipe 103. 102, the return pipe 103 and the liquid reservoir 104 are connected in sequence.

[0088] Wherein, it should be noted that the cultivation device 107 includes: a cultivation tank 102, a return pipe 103, a liquid storage tank 104 and a plurality of upright columns 101; One end is seamlessly connected with the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap