Straw packaging machine

A packaging machine and straw technology, which is applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problem that it is difficult to find the straw belt 81 with more straws or less straws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

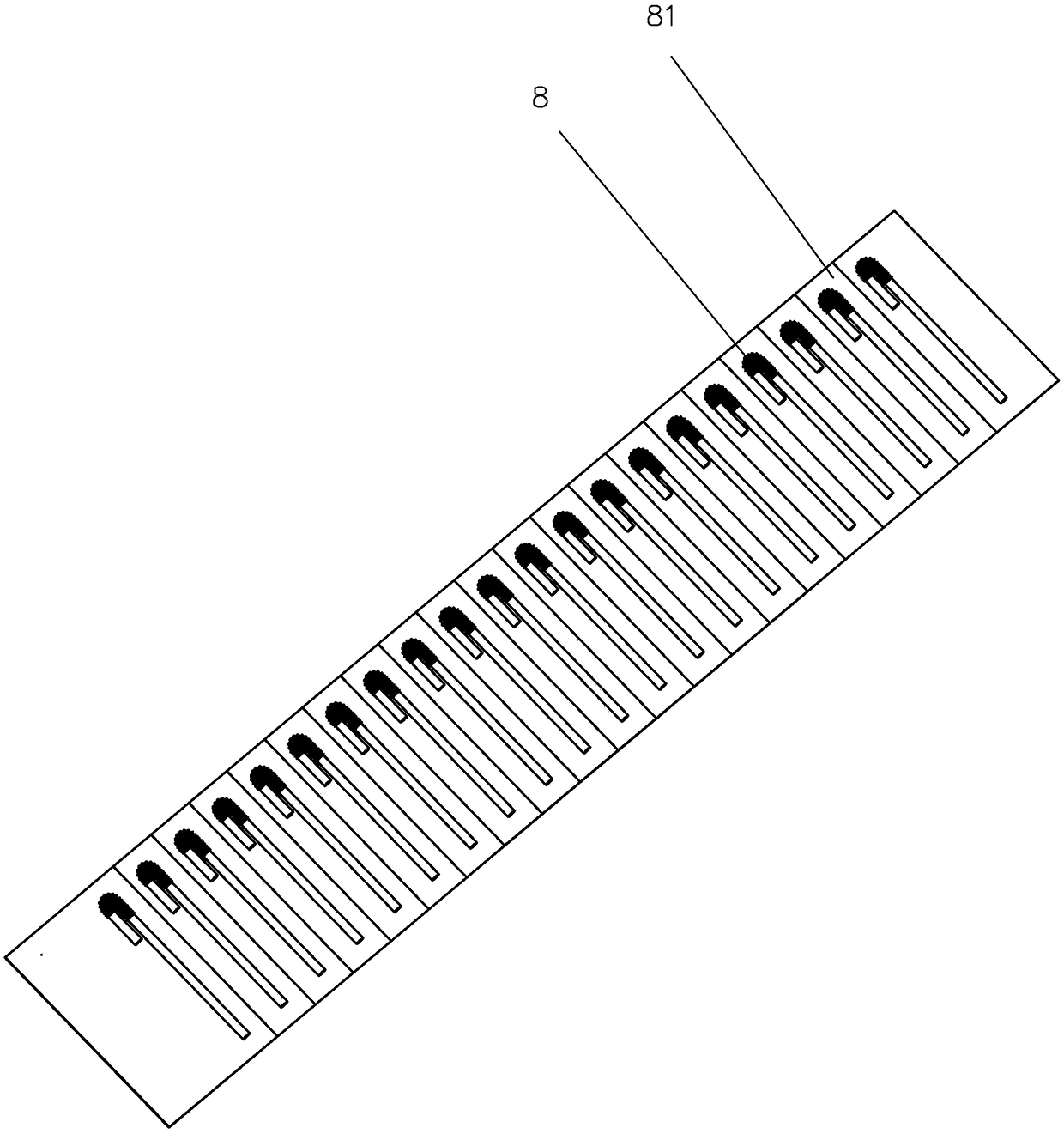

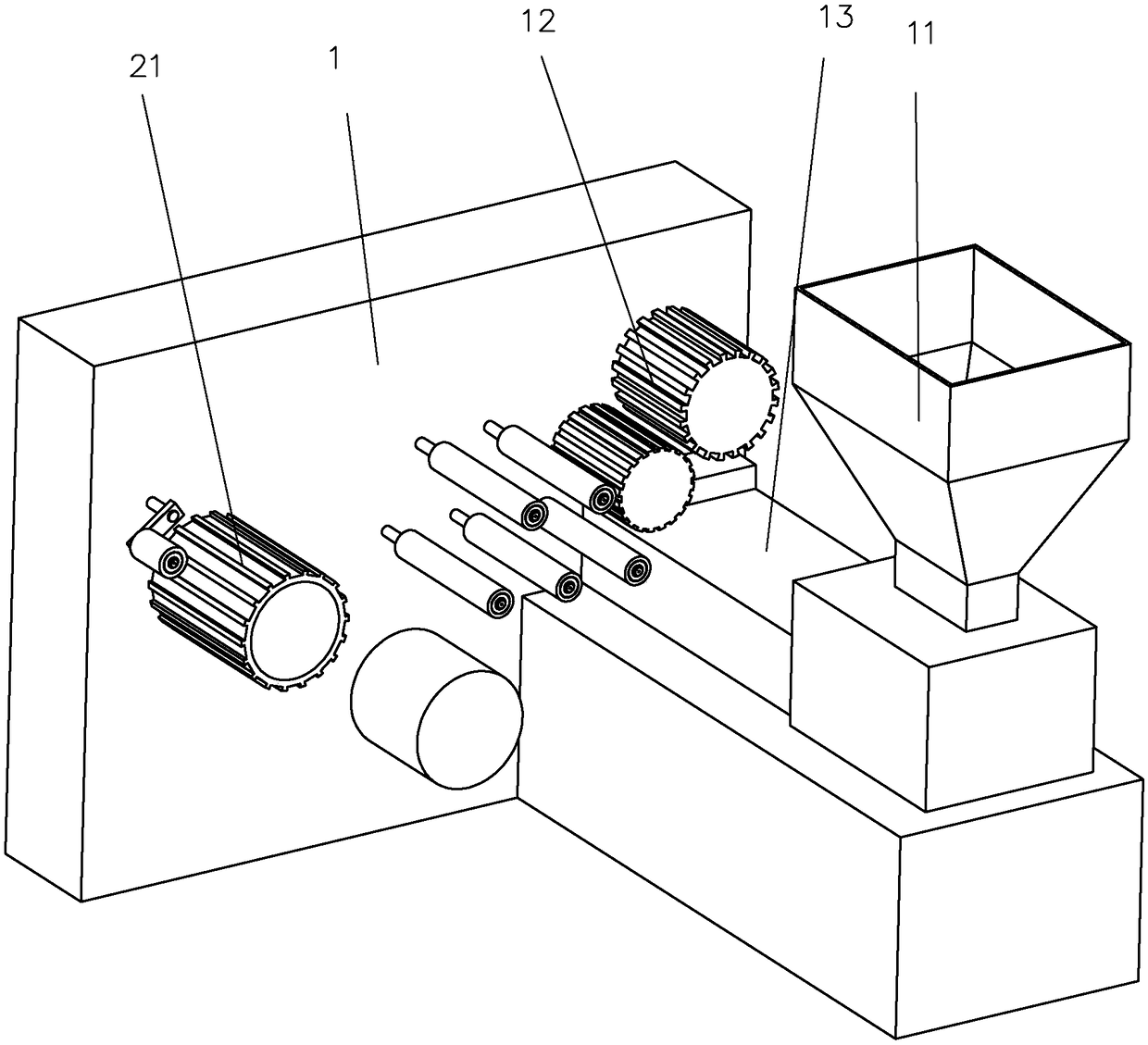

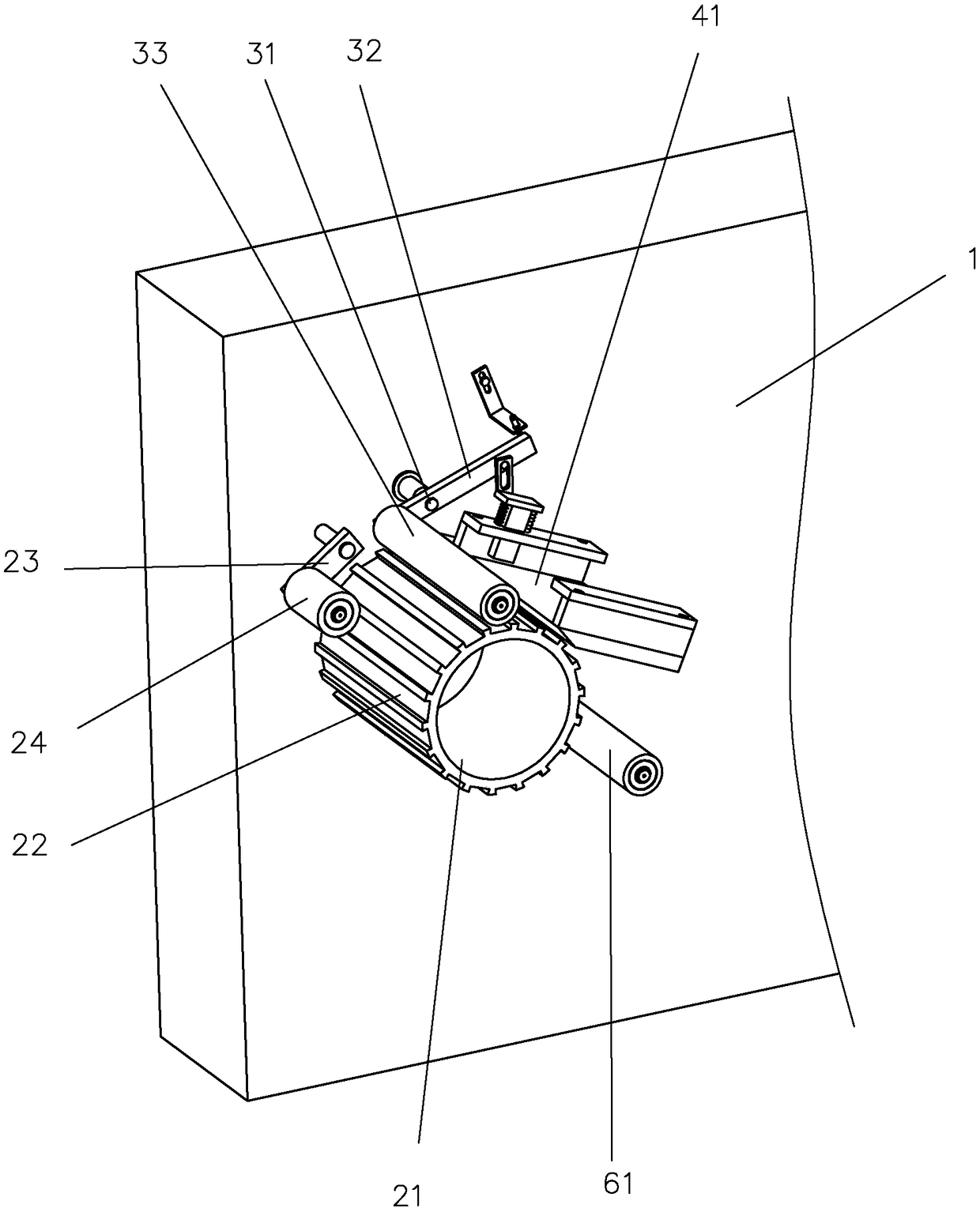

[0033] A straw packaging machine, such as image 3 As shown, it includes a body 1 and a rotating roller 21 arranged on the body 1. The body 1 is provided with a fixed shaft 2, and the rotating roller 21 is rotatably connected to the fixed shaft 2. A device for driving the rotating roller 21 to rotate is provided in the body 1 The driving device (not shown in the figure) is evenly provided with a plurality of bar-shaped grooves 22 on the circumference of the driving roller, so that each straw 8 can be snapped onto the bar when the packaged straw band 81 passes through the rotating roller 21. In the shaped groove 22; on the side of the body 1 close to the rotating roller 21, a receiving plate 23 is rotatably connected, and a pressure roller 24 is rotatably connected on the receiving plate 23, and the pressing roller 24 is pressed on the rotating roller 21, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com