Zigzag cooling mechanism

A cooling mechanism and blanking technology, which is used in the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc., can solve problems such as increasing costs, save energy, prolong falling time, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

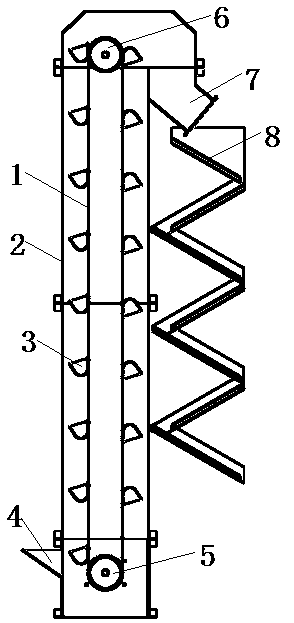

[0013] A zigzag cooling mechanism, comprising a lifting device and a feeding slideway, the lower end of the lifting device is provided with a material inlet, the upper end of the lifting device is provided with a discharge port 4, and the lifting device includes a lifting belt 1, a casing 2, a hopper 3, a feeding Port 4, driving pulley 5, driven pulley 6, discharge port 7, blanking slide 8, and blanking channel 9, the lifting device lifts the coated sand to be cooled to a certain height, and the The casing 2 is a casing placed vertically, the bottom of the casing 2 is provided with a driven pulley 5, the top of the casing is provided with a driving pulley 4, the driving pulley 4 is connected to the power unit, and the driving pulley 4 is connected with the driven pulley 5 through the lifting belt 1, the lifting belt 1 is provided with a plurality of hoppers 2, the discharge port 7 of the lifting device corresponds to the discharge channel 9, and the discharge channel 9 It incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com