A kind of peanut bud production system

A production system, technology of peanut buds, applied in the direction of sowing, sowing seeders, seed and rhizome treatment, etc., can solve problems such as poor production environment, uneven quality of peanut buds, and failure to improve production efficiency, so as to reduce work The effect of high volume and space utilization and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

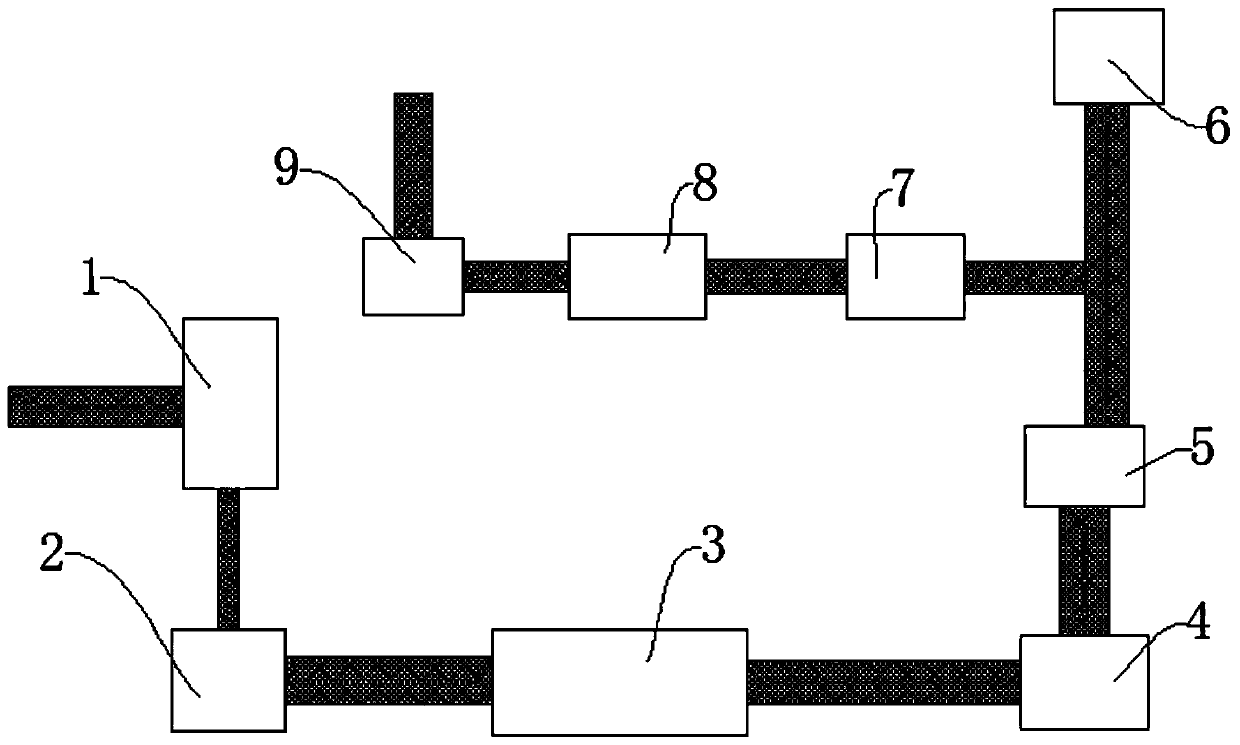

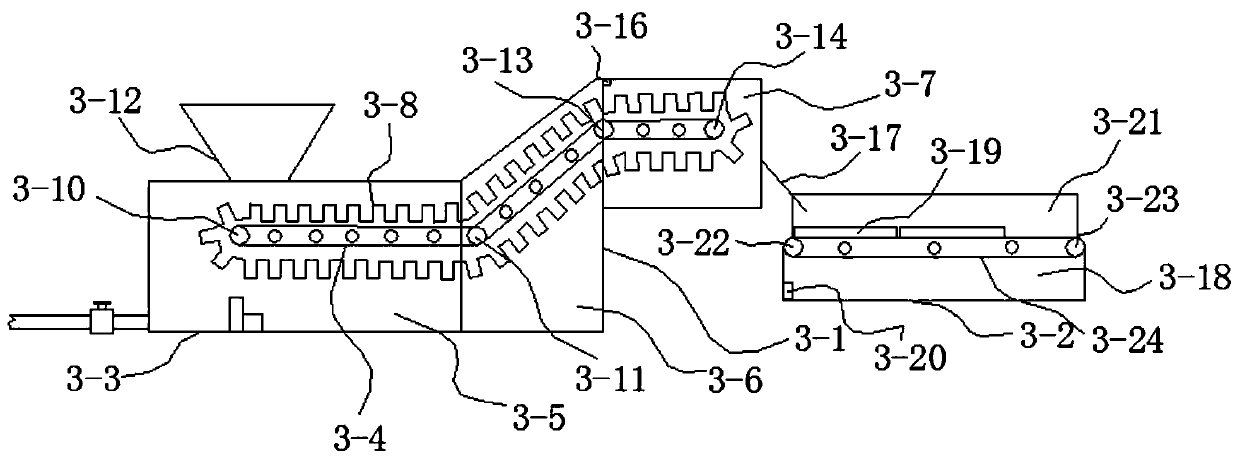

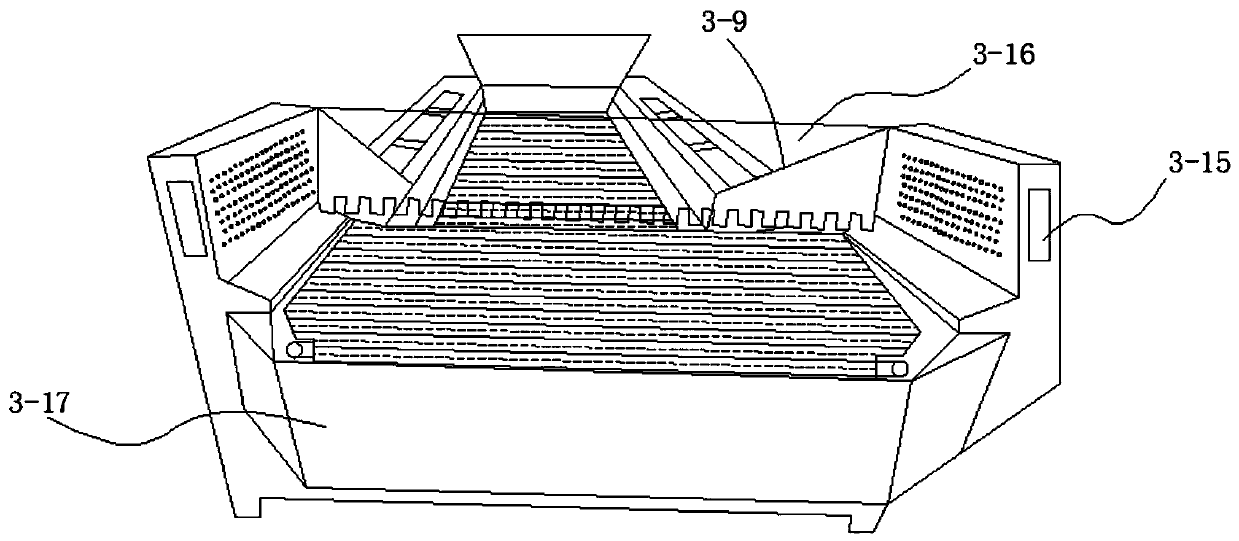

[0039] Such as figure 1 As shown, a peanut bud production system includes an extruding sheller 1, an electrolytic water tank 2 connected to the extruding sheller 1 through a conveyor belt, and a seed soaking and separating device 3 connected to the electrolytic water tank 2 through a conveyor belt , Seed soaking and accelerating germination equipment 4 connected with seed soaking and sorting equipment 3 through a conveyor belt, peanut sprout cultivation equipment 5 connected with seed soaking and germination acceleration equipment 4 through a conveyor mesh belt, planting tray cleaning connected with peanut sprout cultivation equipment 5 through a conveyor mesh belt Equipment 6, root cutting equipment 7 connected with peanut bud cultivation equipment 5 through a conveyor belt, precooling equipment 8 connected with root cutting equipment 7 through a conveyor belt, and sorting packaging connected with precooling equipment 8 through a conveyor belt The equipment 9 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com