An automatic head grooving mechanism for a vehicle ball joint

A ball joint and head technology, used in drilling/drilling equipment, metal processing equipment, boring/drilling, etc., can solve the problems of inconvenient automatic production of ball joint grooves and inconvenient processing of ball joints. , to achieve the effect of simple structure, solving inconvenient processing and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

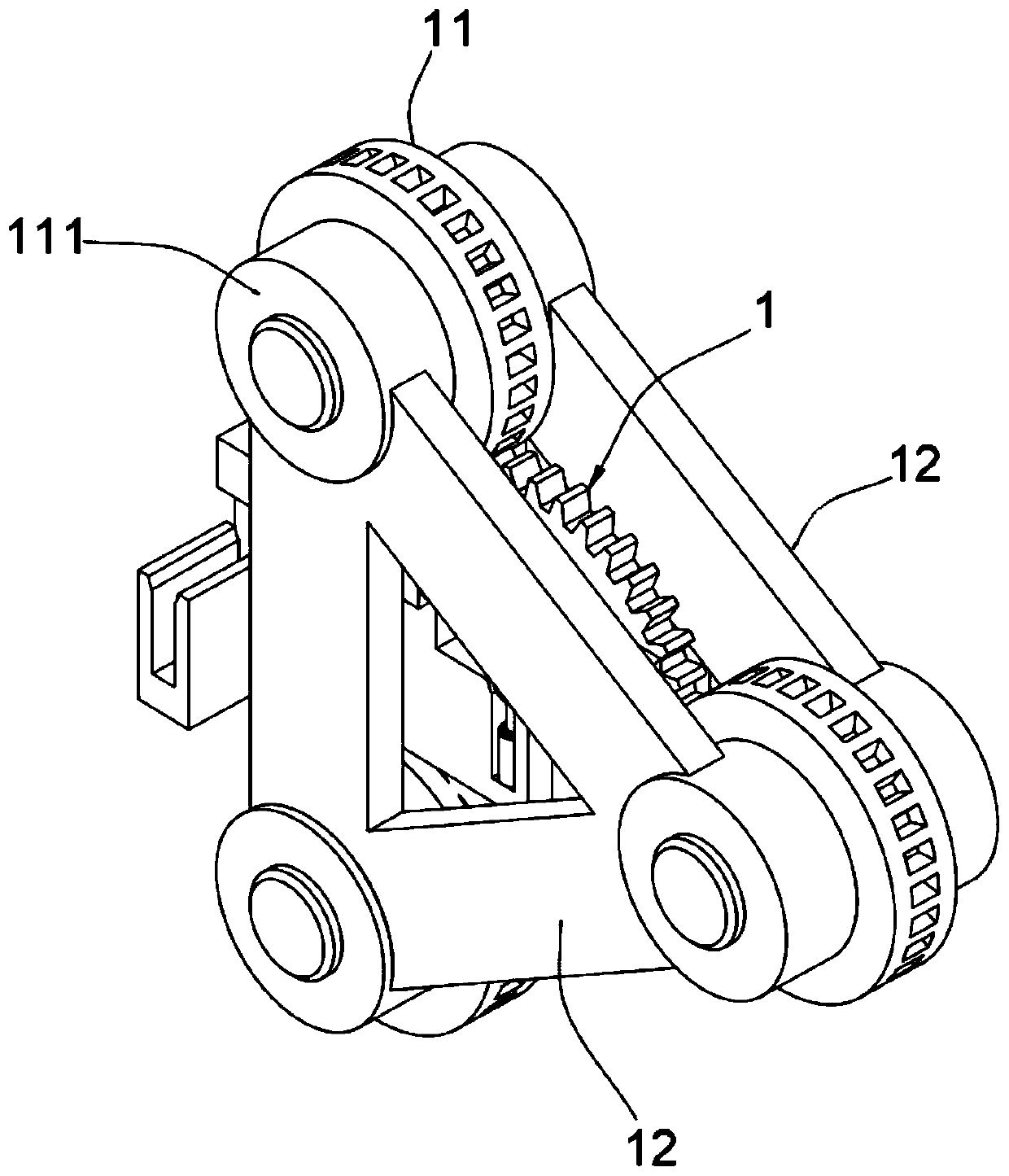

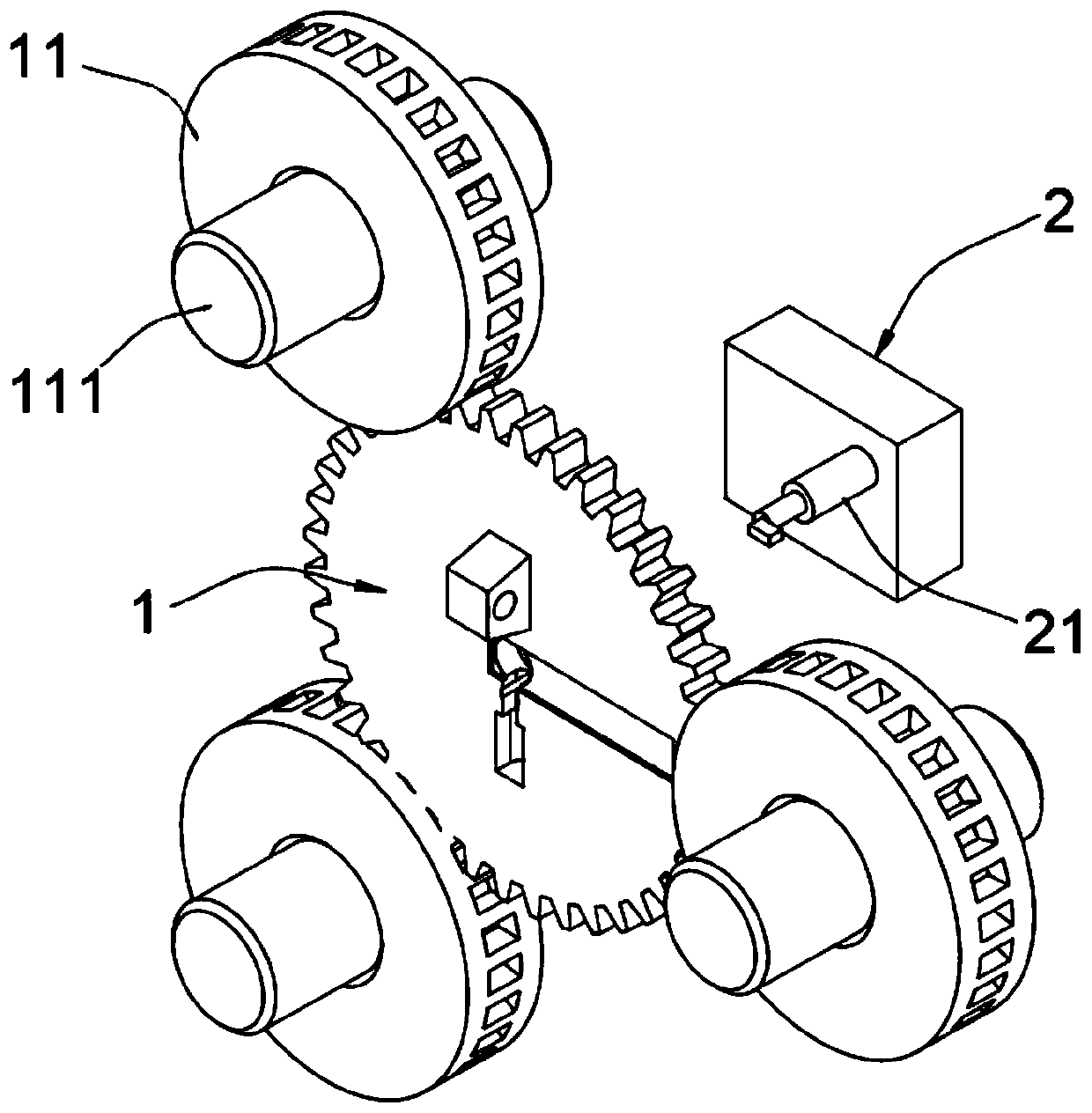

[0027] An automatic head grooving mechanism for a ball joint for vehicles, such as figure 1 , image 3 , Figure 4 with Figure 5 As shown, including the driven wheel 1, the driven wheel 1 is provided with three driving wheels 11, each driving wheel 11 is provided with a rotating shaft 111, and the front and rear end faces of the driving wheels 11 are provided with triangular baffles 12, and the triangular baffles The three tops of 12 are tightly welded with the three rotating shafts 111, and a groove 13 is arranged at the center of the front surface of the driven wheel 1, and a slotted hole 131 is arranged at the top of the bottom wall of the groove 13, and the bottom wall of the groove 13 is located at Below the slotted hole 131, several blanking holes 132 are arranged, and a slideway 14 is arranged on the side where the front surface of the driven wheel 1 is positioned at the groove 13, and the slideway 14 communicates with the groove 13, and the front surface of the driv...

Embodiment 2

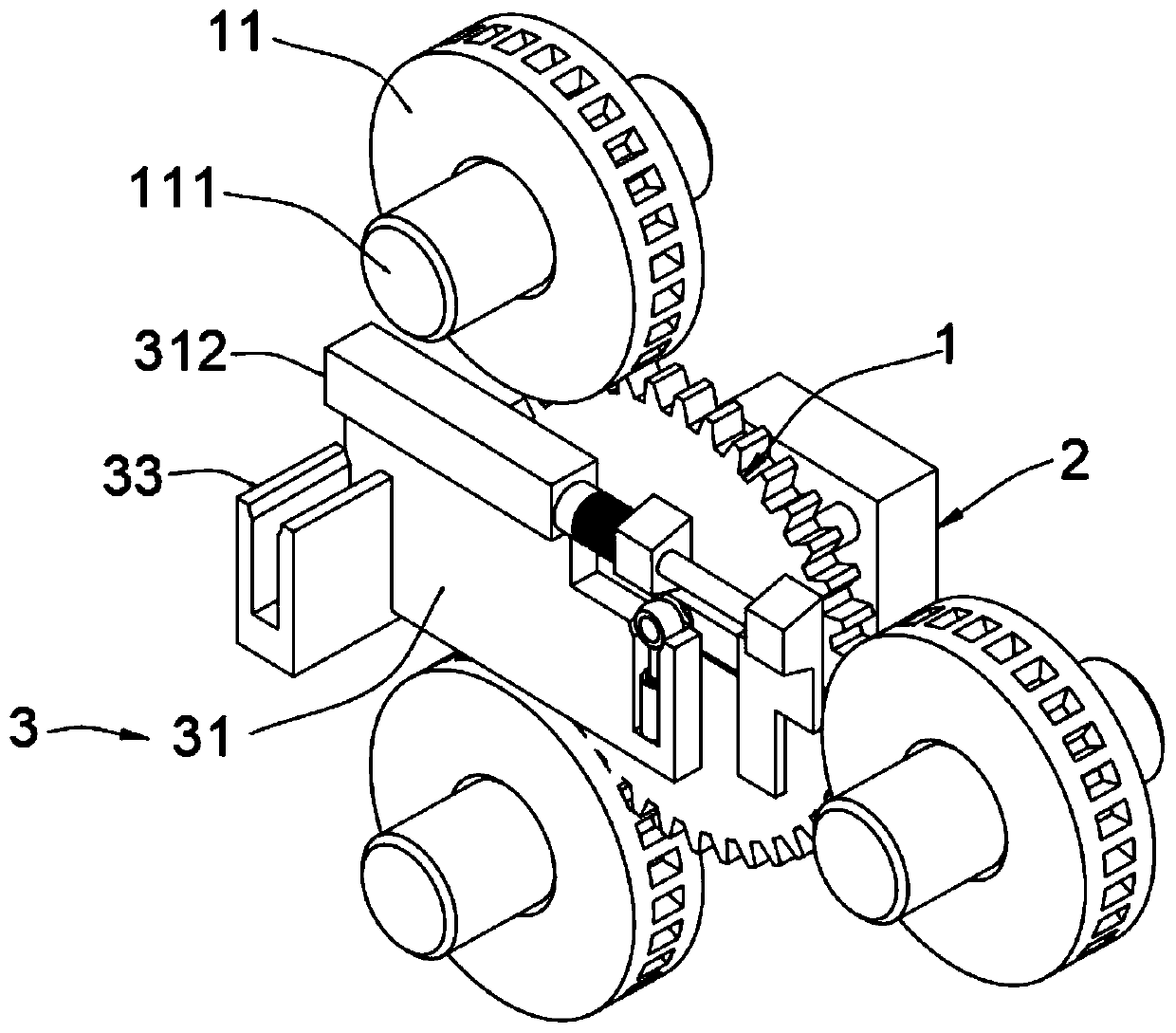

[0034] As a second embodiment of the present invention, in order to facilitate the automatic production of ball joints, the inventors improved the structure of the driven wheel 1, as a preferred embodiment, such as figure 2 with Image 6 As shown, the driven wheel 1 is provided with a pusher mechanism 3, the pusher mechanism 3 includes a pusher plate 31 arranged on the front end of the driven wheel 1, one end of the pusher plate 31 is provided with a gap 311, and the gap 311 runs through the pusher plate 31. The top of the pusher plate 31 is tightly welded with an L-shaped plate 312. One end of the L-shaped plate 312 is provided with a telescopic rod 32. The telescopic rod 32 is provided with a spring 321. One end of 32 is tightly welded with a fixed block 322, the other end of the telescopic rod 32 is tightly welded with a slide plate 323, the bottom end of the pushing plate 31 is provided with a feeding block 33, and the feeding block 33 is provided with a vertical groove 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com