Improved curved surface positioning tapper

A hole saw, an improved technology for use in boring/drilling, drilling/drilling equipment, maintenance and safety accessories, which can solve difficult-to-drill centers, easily splashed debris, and affect drilling operations Platform and other problems, to achieve the effect of accurate positioning and opening, good stability, and easy collection and centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

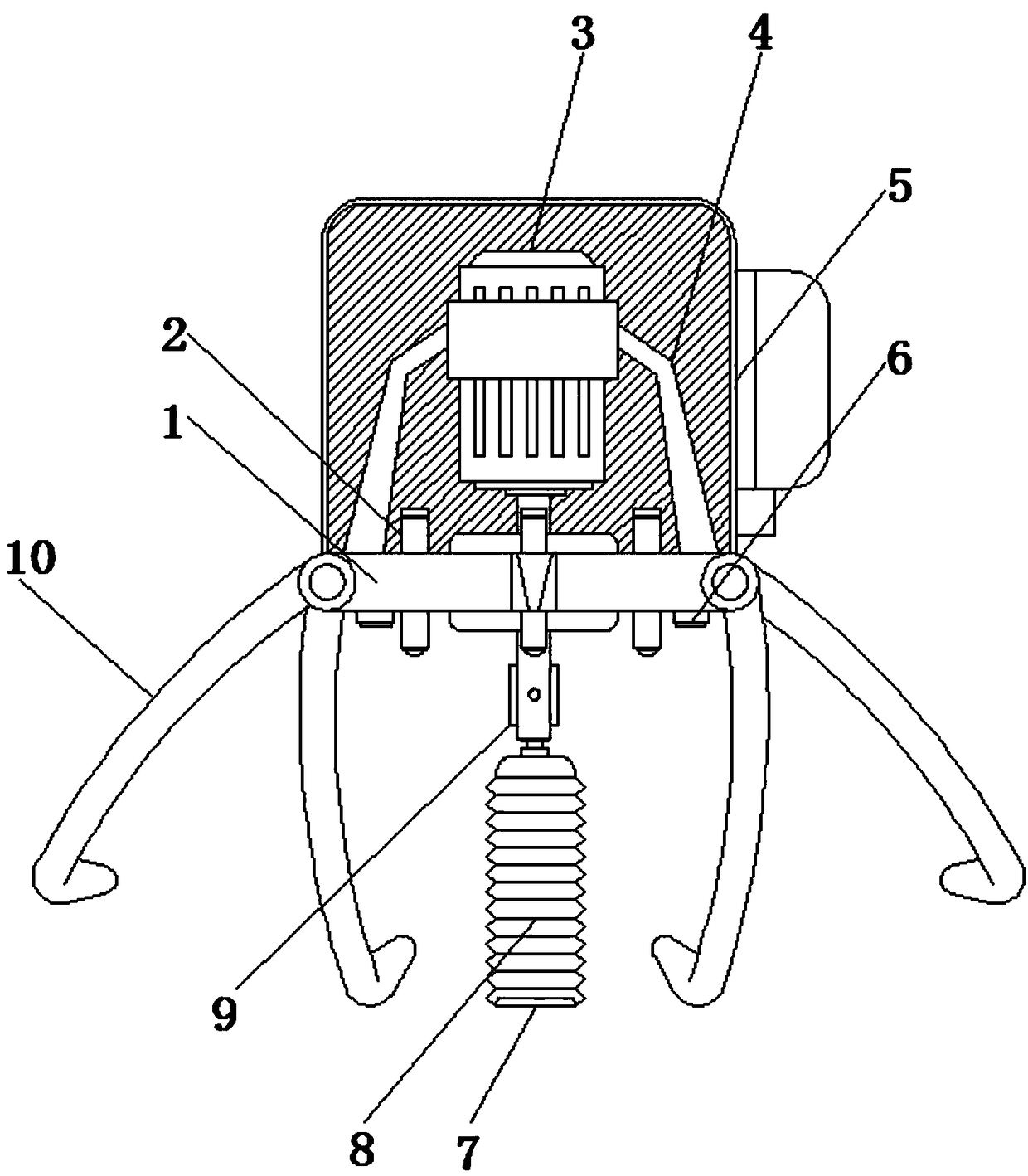

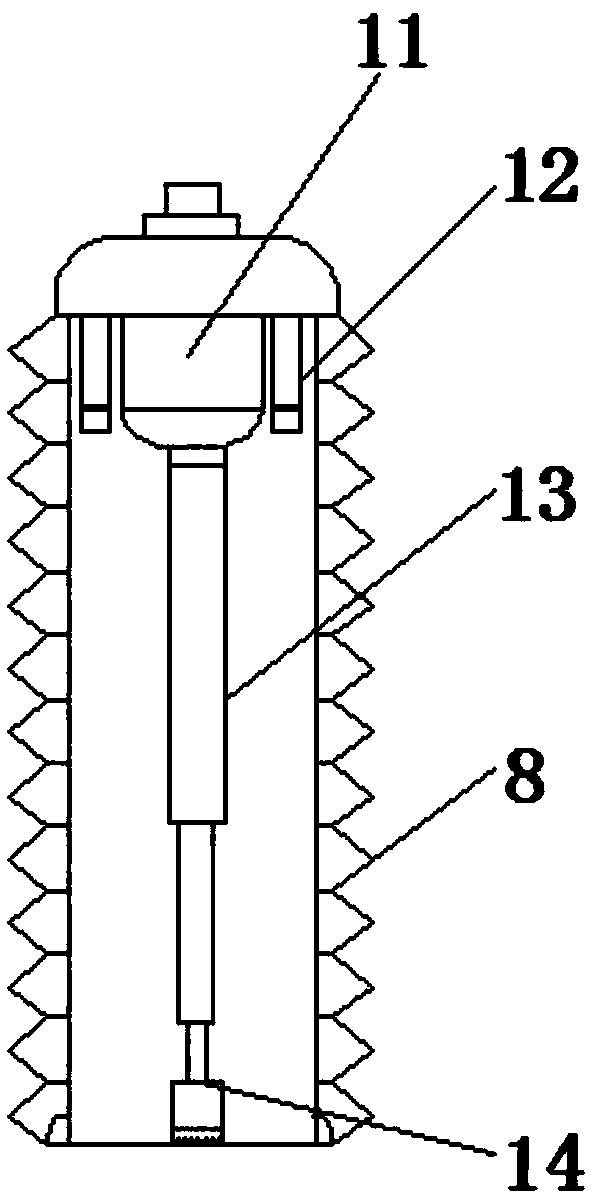

[0015] refer to Figure 1-2 , an improved curved surface positioning hole opener, including a center plate 1, the outer walls of the four sides of the center plate 1 are fixed with hooks 10 through hinges, and the top outer wall of the center plate 1 is provided with a card slot, and the inner wall of the card slot is carded. Soundproof cover 5, support brackets 4 are welded on both sides of the top outer wall of the center plate 1, and the top inner wall of the bracket 4 is fixed with a servo motor 3 by bolts, and the output shaft of the servo motor 3 is welded with a quick chuck 9, and the quick chuck 9 The bottom inner wall of the central disk 1 is clamped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com