Rigid coaxial cable stripping device and cable stripping technology

A technology of coaxial cable and wire stripping device, applied in cable installation device, cable installation, circuit/collector parts and other directions, can solve the problems of low production efficiency, low qualification rate, tool wear and so on, and achieve accurate size , prolong the service life and avoid the effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

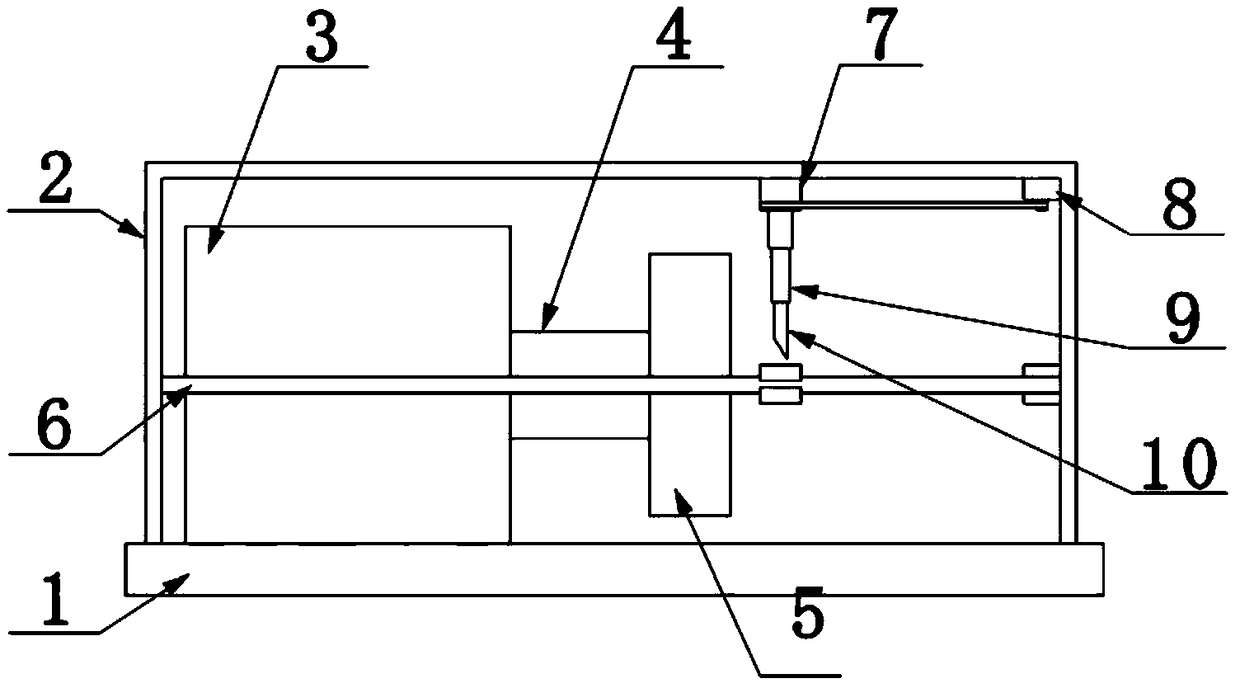

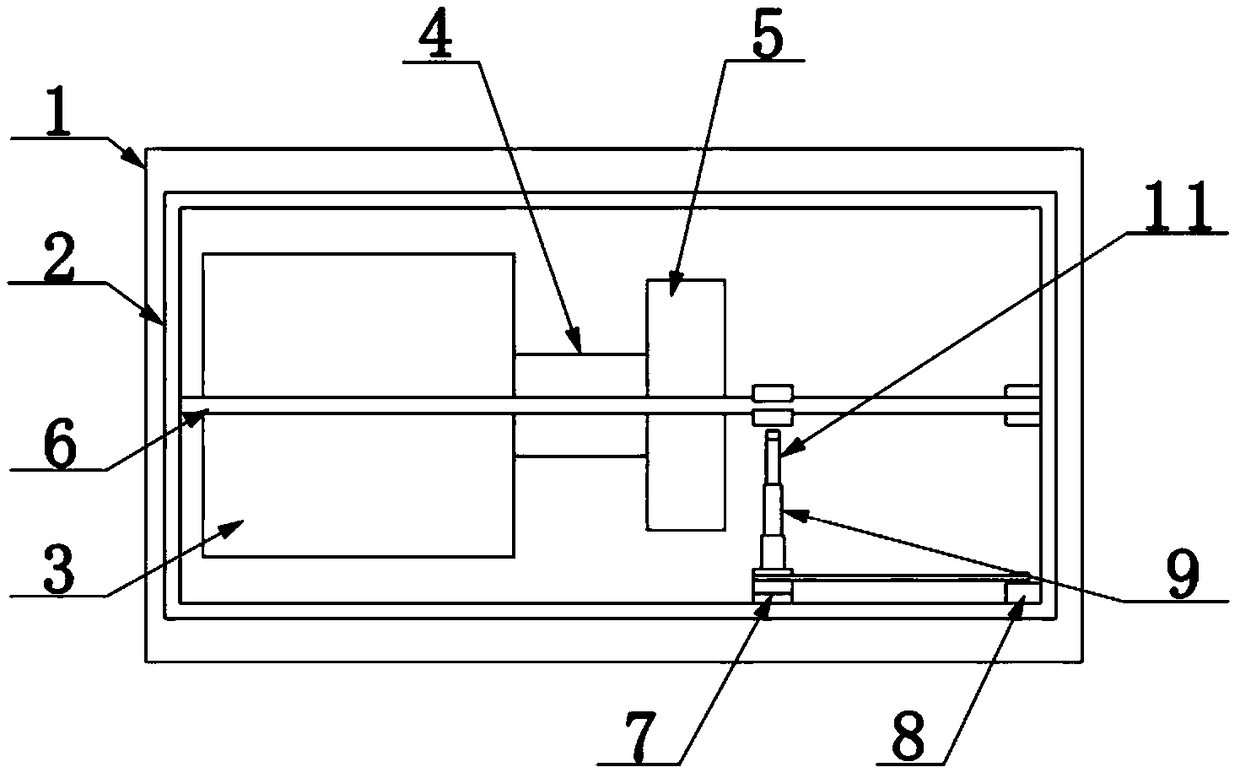

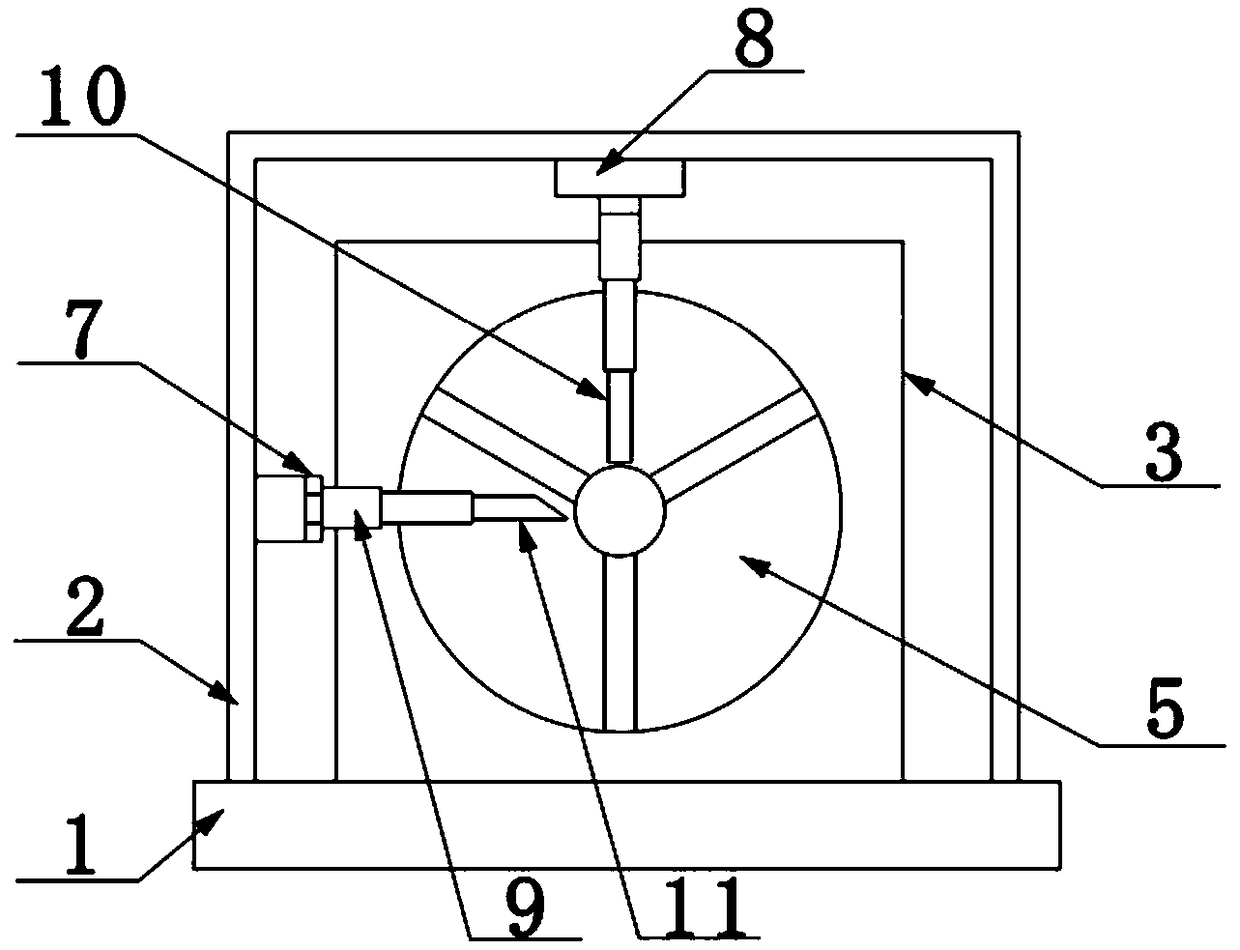

[0036] In order to solve the problems that the existing automatic wire stripping machine cannot clamp the cable when stripping the rigid coaxial cable, the tool wears seriously, the production efficiency is low, and the qualified rate after stripping is low, the invention provides a rigid coaxial cable Cable stripping device and corresponding stripping process, the rigid coaxial cable stripping device in the present invention is as Figure 1~3 Shown, comprise base 1, and base 1 is square, and stripping machine tool 3 is installed on its seat surface, and stripping machine tool 3 is common lathe, and it comprises machine tool main body and the main shaft 4 that is movably connected with machine tool main body, and machine tool main body is welded It is fixed on the base 1 by means of bolt connection or other means, which provides power for the main shaft 4, so that the main shaft 4 can rotate around the center; the end of the main shaft 4 is equipped with a chuck 5 through a det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com