Butt joint clamping groove mechanism for loader

A technology for loading trucks and card slots, applied in the directions of wrenches, manufacturing tools, wrenches, etc., can solve the problem of low efficiency, and achieve the effects of convenient operation, simple structure and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

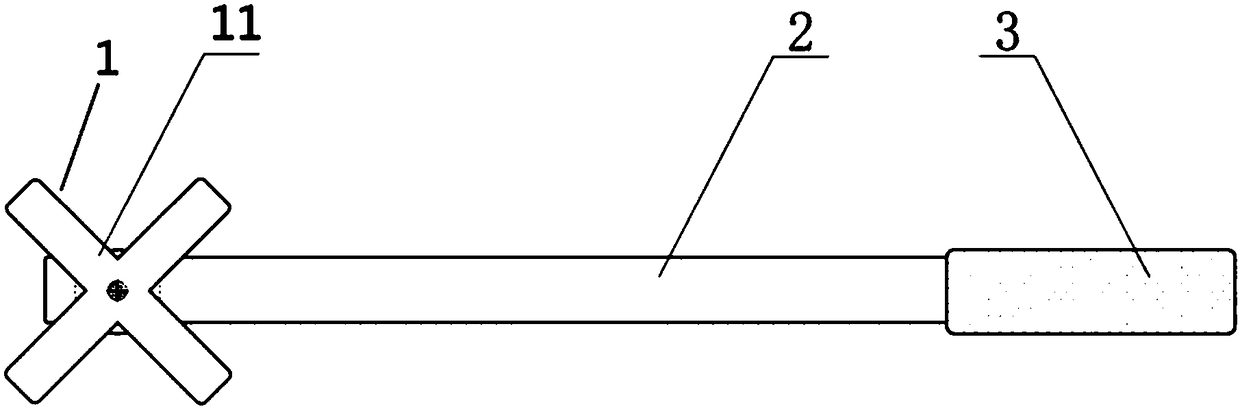

[0015] The invention provides a loading and unloading tool for external thread protection wires of oil drilling tools. The loading and unloading tool includes: a rod body and a working head fixed at one end of the rod body, and the working head is engaged with the groove on the external thread protection wire. Then, when the working head is connected with the groove on the external thread protection wire, the axis of the rod body is perpendicular to the rotation axis of the external thread protection wire.

[0016] Such as figure 1 As shown, the working head is a "ten"-shaped working head, which is formed by connecting four single teeth 11. The cross section of the single teeth 11 is square or rectangular, and the four single teeth 11 are connected with the external thread protection wire 5 The groove 51 on the top is correspondingly engaged. An operating handle 3 is also provided on the rod body 2 , and the operating handle 3 and the working head 1 are respectively fixed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com