Rectifying device, mounting device, rectifying method

A technology for installing heads and leads, applied to electrical components, electrical components, etc., can solve the problems of reduced production cycle, correction failure, and increase in the number of retries of correction actions, and achieve the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

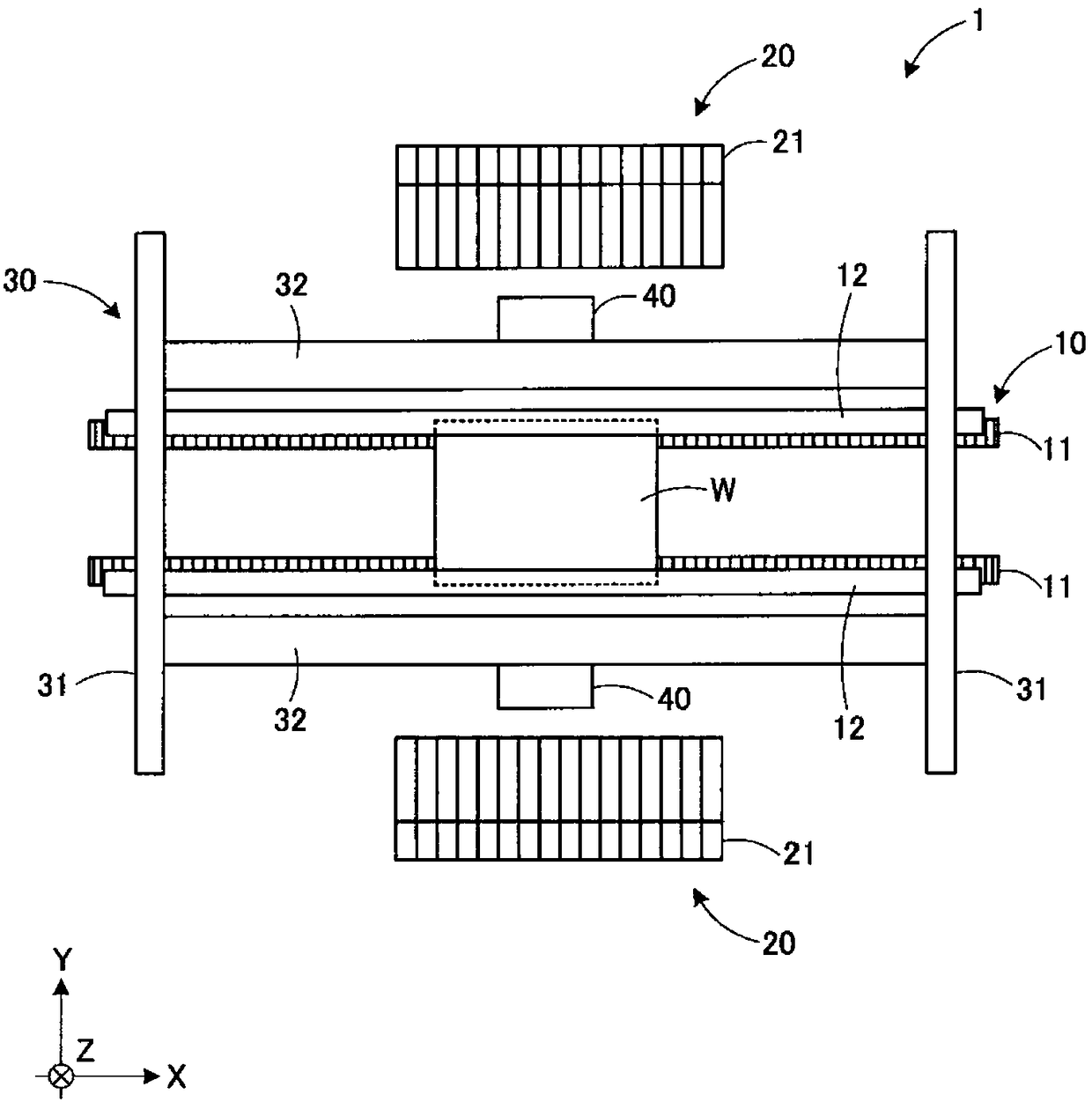

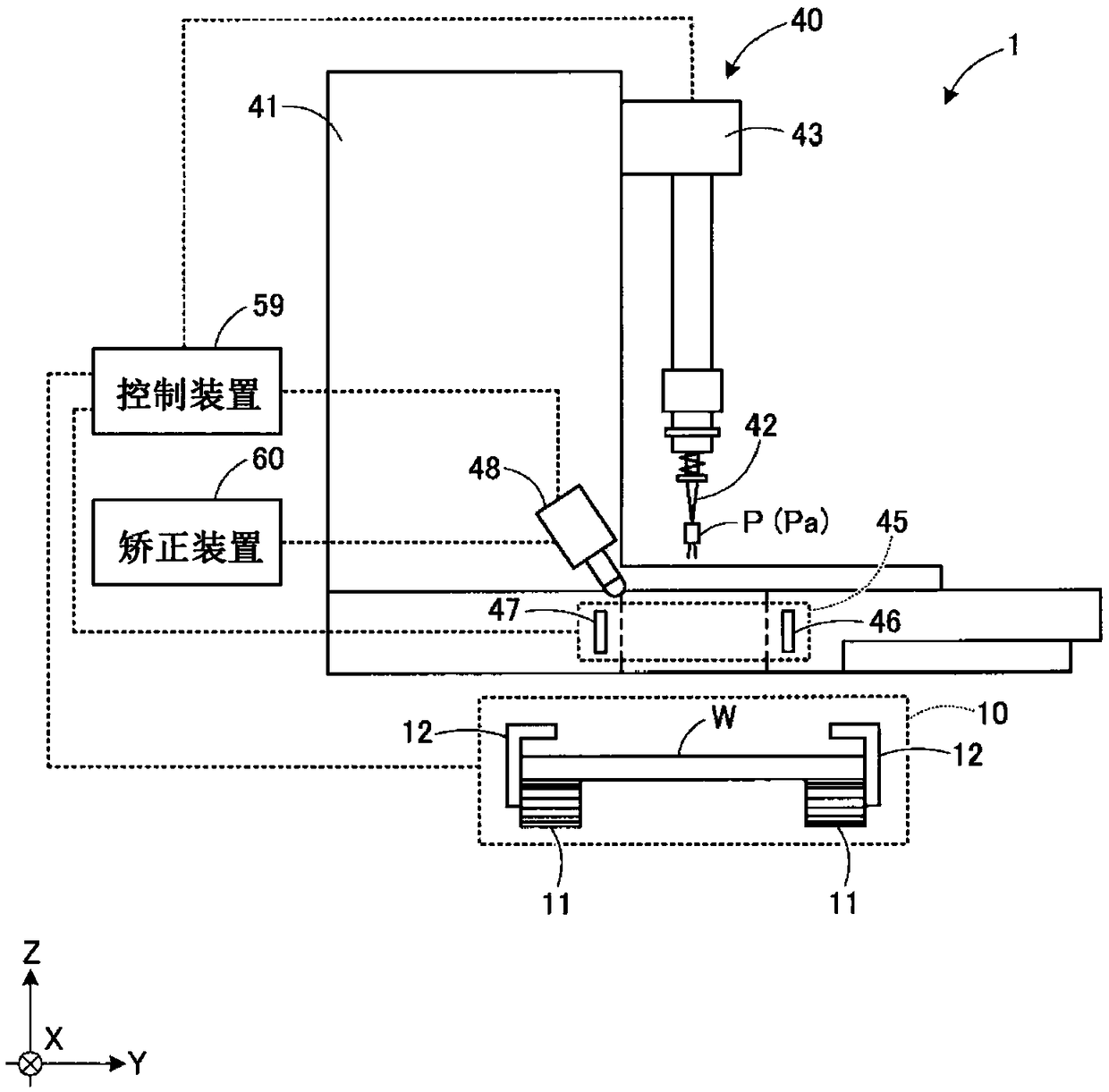

[0038] Hereinafter, the mounting device of the present embodiment will be described with reference to the drawings. figure 1 It is a schematic diagram showing the whole mounting apparatus of this embodiment. figure 2 It is a schematic diagram showing the periphery of the mounting head of this embodiment. Fig. 3 is a diagram showing an example of the correction operation of the lead member. In addition, the mounting apparatus of this embodiment is only an example, and can be changed suitably.

[0039] Such as figure 1 As shown, the mounting device 1 is configured to supply various parts P (refer to figure 2 ) It is mounted on a predetermined position of the substrate W by a pair of mounting heads 40. The mounting device 1 is provided with a substrate transport unit 10 that transports the substrate W in the X-axis direction. The substrate transport section 10 includes a pair of conveyor belts 11 that transport the substrate W and a pair of guide rails 12 that guide the transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com