Latex composition for dip molding, and shaped articles prepared therefrom

A technology of dip molding and composition, applied to the latex composition used for dip molding, which can solve the physical properties of gloves (low tensile strength, elongation and modulus, long cross-linking aging of sulfur, glove denaturation, etc. problems, to achieve the effect of improving durability, improving syneresis, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

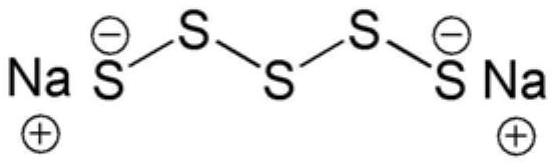

[0035] In the present invention, the preparation of the aqueous solution of sodium polysulfide is not particularly limited, and can be prepared by methods known in the art. For example, the aqueous solution is prepared by dissolving sodium sulfide in distilled water to prepare a strongly alkaline aqueous solution, and then adding sulfur (S 8 ) powder [Macromol.Rapid Commun.2015,36,1103-1107] to prepare. At this time, considering the precipitation of sulfur in the aqueous solution, it is preferable that the concentration of the sodium polysulfide solution is 5% by weight to 20% by weight.

[0036] Such sodium polysulfide is used in an amount of 0.1 to 5 parts by weight, preferably 0.5 to 1 part by weight, relative to 100 parts by weight of the carboxylic acid-modified nitrile copolymer latex in terms of solid content. If the content of sodium polysulfide is less than the above range, the above effects cannot be ensured. On the contrary, if it exceeds the above range, syneresi...

Embodiment 1

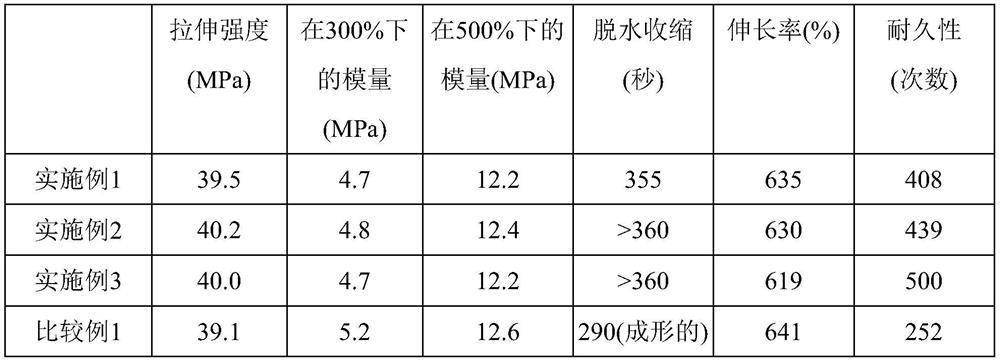

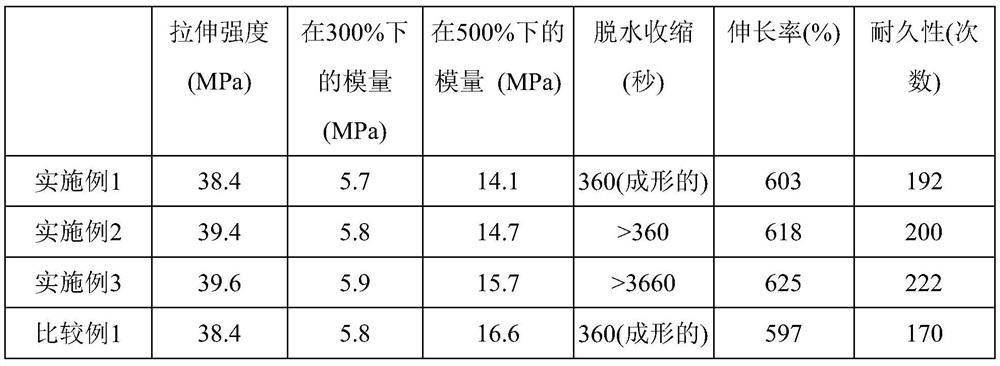

[0091] Embodiment 1: The latex composition that is used for dip molding and the preparation of dip molding article

[0092] (Preparation of Carboxylic Acid Modified Nitrile Copolymer Latex)

[0093] A 10 L high pressure reactor equipped with a stirrer, thermometer, condenser and nitrogen inlet and configured for continuous addition of monomer, emulsifier and polymerization initiator was replaced with nitrogen. Thereafter, 2.5 parts by weight of alkane was added to the high-pressure reactor with respect to 100 parts by weight of a monomer mixture of 25% by weight of acrylonitrile, 70% by weight of 1,4-butadiene and 5% by weight of methacrylic acid. Sodium phenyl sulfonate, 0.5 parts by weight of tert-dodecyl mercaptan and 140 parts by weight of ion-exchanged water were added, and the temperature was raised to 48°C.

[0094] After raising the temperature, 0.25 parts by weight of potassium persulfate as a polymerization initiator was added. When the conversion reached 95%, the ...

Embodiment 2

[0103] Embodiment 2: The latex composition that is used for dip molding and the preparation of dip molding article

[0104] A latex composition for dip molding was prepared in the same manner as in Example 1 except that hydrophilic sodium polysulfide was used in a proportion of 0.7 parts by weight, and a glove-shaped dip molding article was prepared using it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com