A drift step recovery diode

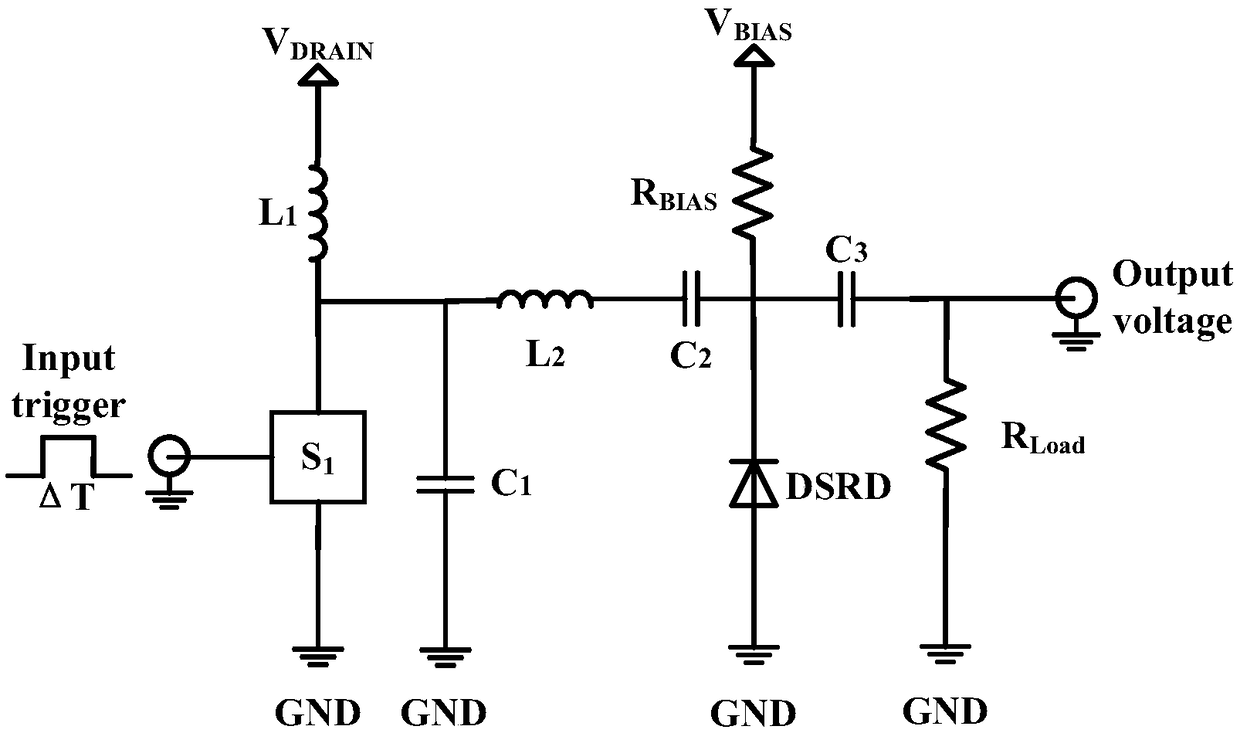

A recovery diode and anode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large power consumption, low voltage pulse peak value, and increased device withstand voltage of drift step recovery diodes, so as to reduce the average moving distance. , the voltage change rate is large, the effect of accelerating the extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing

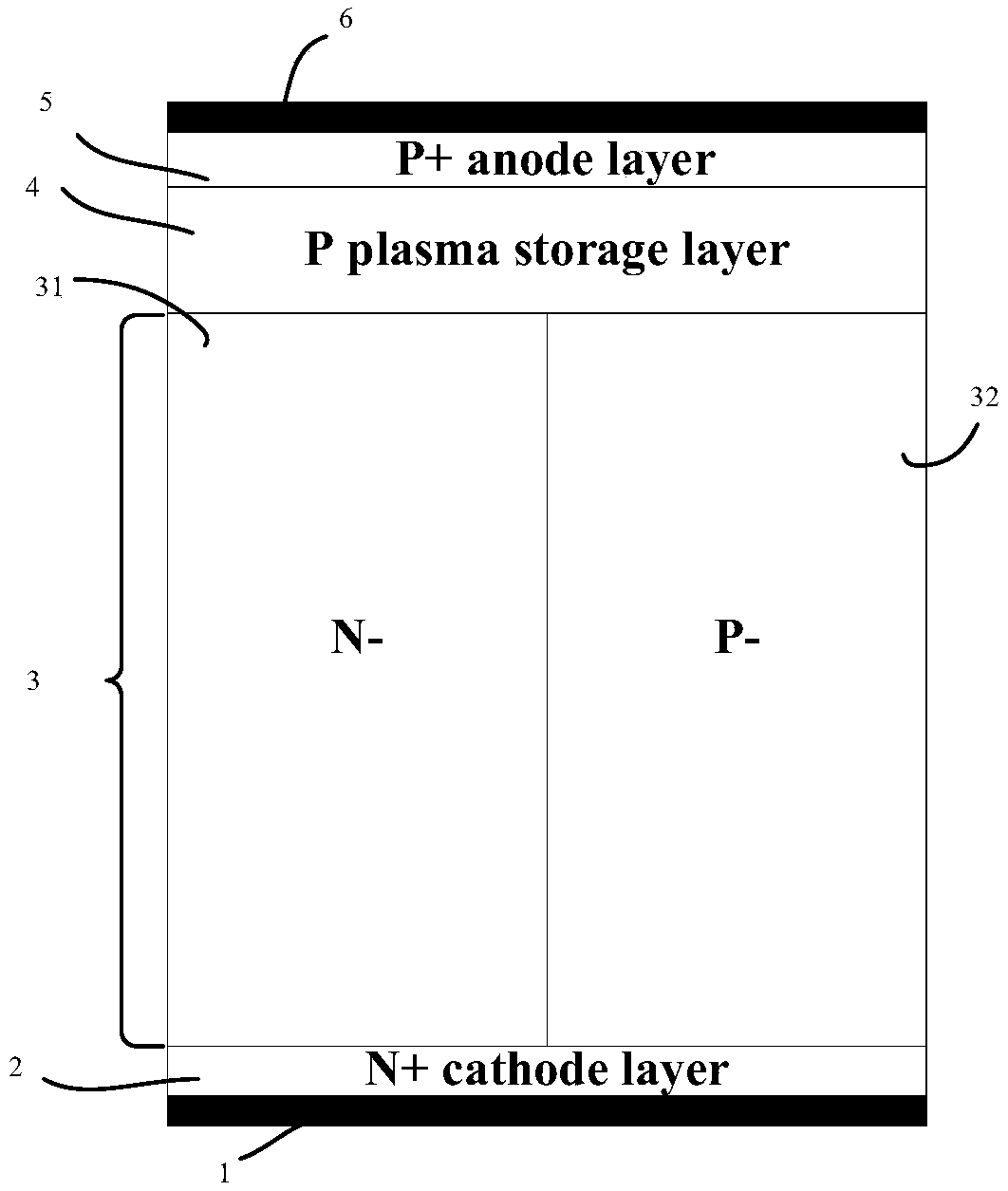

[0014] Such as figure 2 As shown, the drift step recovery diode of the present invention has a cell structure including N-type ohmic contact electrode 1, N-type heavily doped cathode region 2, super-junction withstand voltage base region 3, and P-type plasma from bottom to top. Storage layer 4, P-type heavily doped anode 5, P-type ohmic contact electrode 6; the super junction withstand voltage base region 3 includes N-column region 31 and P-column region 32; it is characterized in that, compared to the conventional p + -p-n 0 -n + For the drift step recovery diode, the withstand voltage base region of the drift step recovery diode of the present invention adopts a super junction structure.

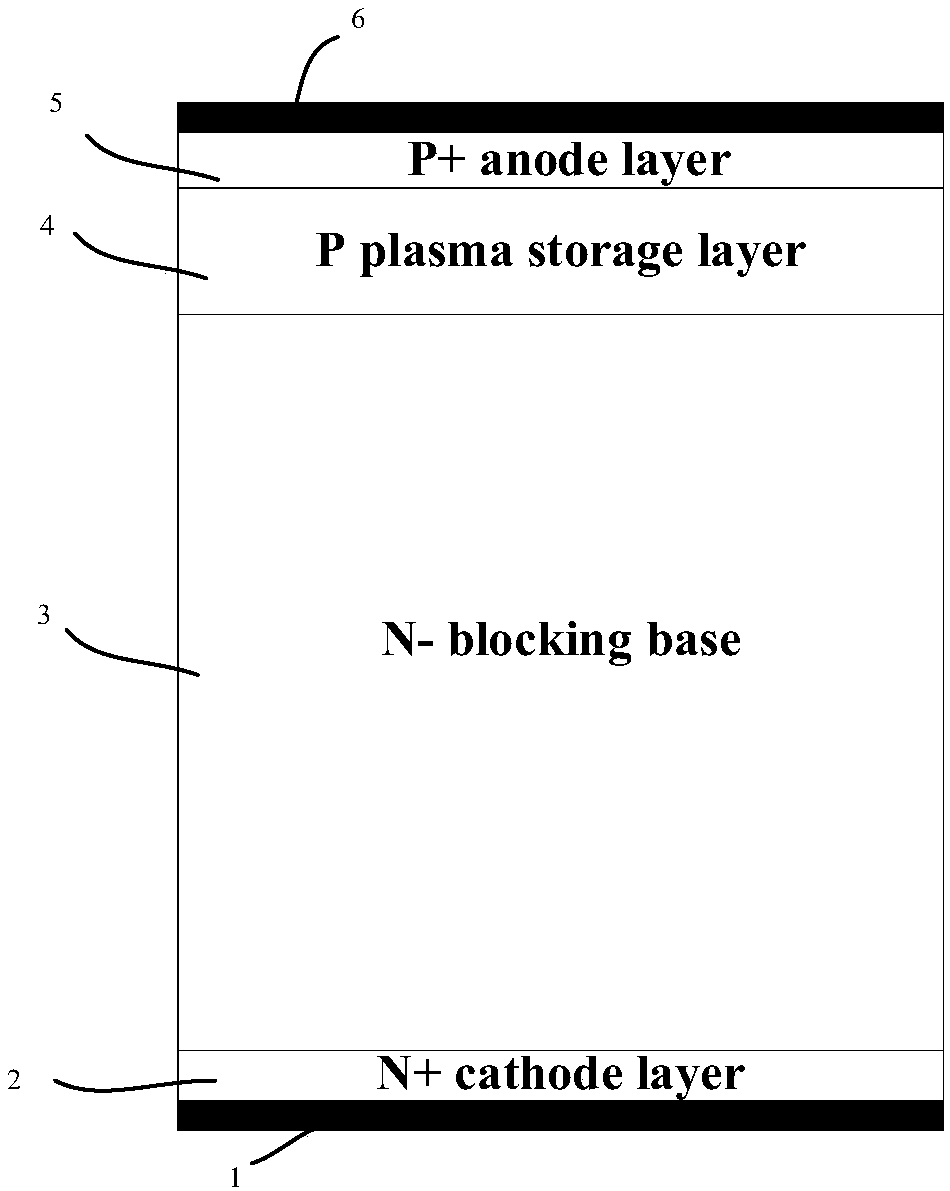

[0015] Such as figure 1 shown, for the conventional p + -p-n 0 -n + drift step recovery diode. Such as figure 2 Shown is the drift step recovery diode of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com