Light-permeable cover plate and mobile terminal

A light-transmitting cover and mobile terminal technology, which is applied in the field of communication, can solve the problems of large signal wave background noise, etc., and achieve the effect of reducing background noise and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

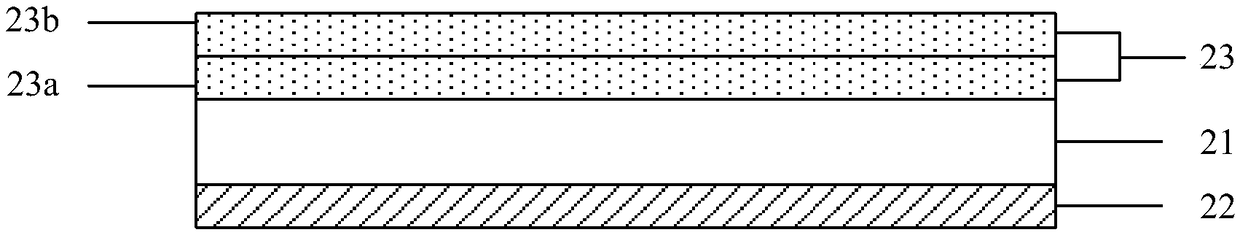

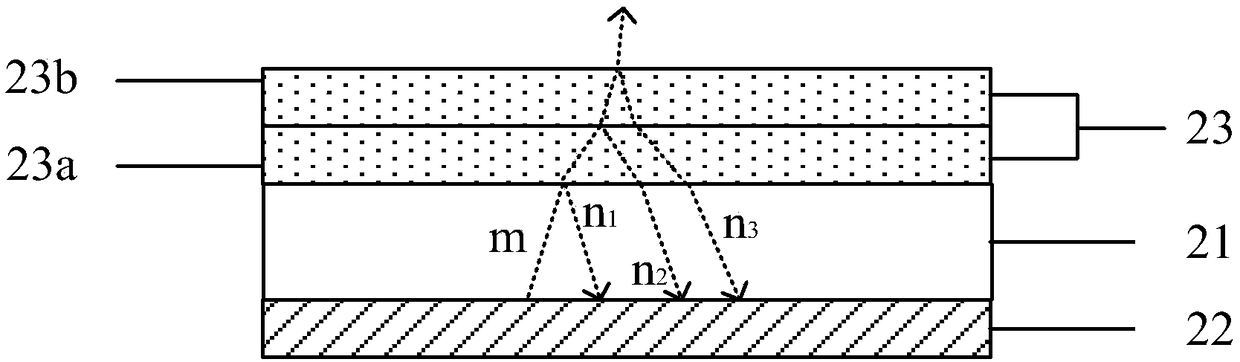

[0027] The embodiment of the present application provides a light-transmitting cover plate, figure 2 It is a schematic structural diagram of the light-transmitting cover, and the light-transmitting cover includes:

[0028] The light-transmitting cover body 21;

[0029] The light-transmitting film layer 23 is provided on the first side surface of the light-transmitting cover plate body 21, and includes at least two layers of light-transmitting films stacked in sequence;

[0030] The ink layer 22 is provided on the second side surface of the transparent cover body 21;

[0031] Wherein, the refractive index of the light-transmitting film adjacent to the light-transmitting cover body 21 is greater than the refractive index of the light-transmitting cover body 21, and the respective refractive indices of the at least two layers of light-transmitting films vary with each other. The distance between the transparent cover body 21 decreases; or, the refractive index of the transpare...

Embodiment 2

[0062] Based on the solutions described in the above embodiments, the present application also provides a light-transmitting cover plate to further illustrate the solution, as shown in Figure 5 As shown, the light-transmitting cover plate provided by this application includes:

[0063] A light-transmitting cover plate body 51, one side of the light-transmitting cover plate body 51 is coated with an ink layer 52;

[0064] At least two layers of light-transmitting films 53 located on the other side of the light-transmitting cover plate body 51;

[0065] Wherein, the refractive index of any transparent film 53 is related to the distance between the transparent film 53 and the transparent cover body 51 .

[0066] like Figure 5 As shown, in this example, the light-transmitting film on one surface of the light-transmitting cover body 51 has 4 layers in total, from close to the light-transmitting cover body 51 to away from the light-transmitting cover body 51 in sequence: the fir...

example 1

[0069] The refractive index of the first transparent film 53a is greater than the refractive index of the transparent cover body 51, the refractive index of the second transparent film 53b is smaller than that of the first transparent film 53a, and the refractive index of the third transparent film 53c is smaller than that of the first transparent film 53a. The refractive index of the second transparent film 53b and the refractive index of the fourth transparent film 53d are smaller than the refractive index of the third transparent film 53c.

[0070] Based on the structure shown in this example, when light radiates from the ink layer 52 to the outside, the light reflected at the contact surface between the first light-transmitting film 53a and the second light-transmitting film 53b can offset the contact between the light-transmitting cover body 51 and the first light-transmitting film. The light reflected at the contact surface of the transparent film 53a. Specifically, beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com