Self-balancing structure for bend shear test in plane of steel plate concrete wall, and manufacturing method of structure

A steel plate concrete, self-balancing technology, applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve problems such as failure to meet test requirements, large wall thickness, and poor local connection bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

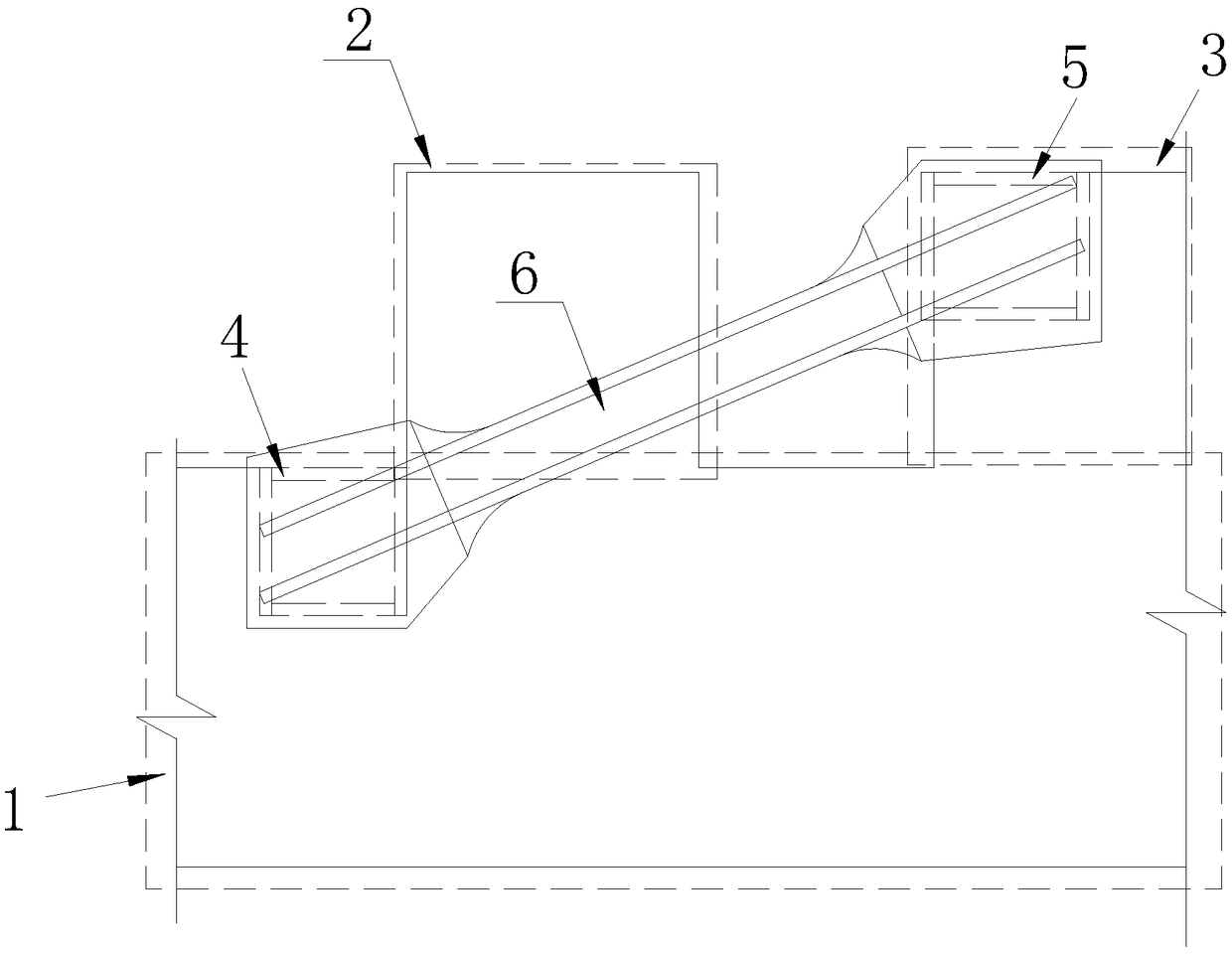

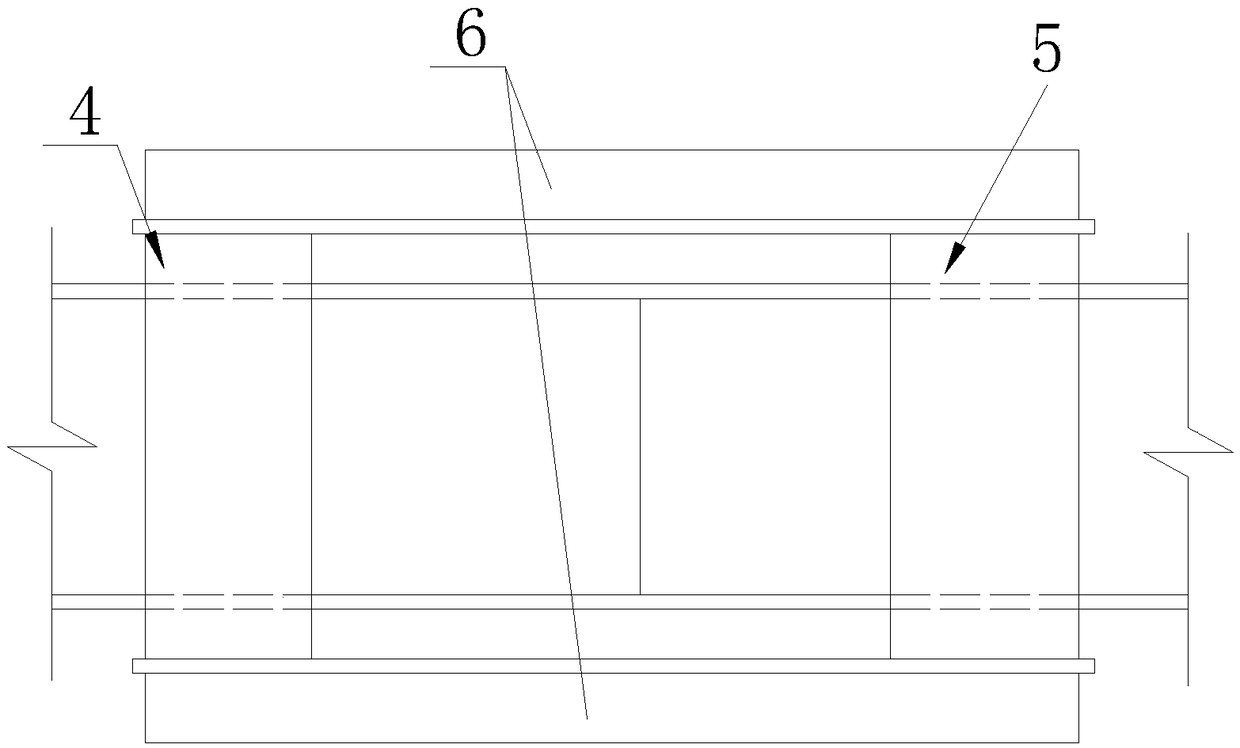

[0026] Such as figure 1 As shown, the steel plate concrete wall in-plane bending-shear test self-balancing structure provided by an embodiment of the present invention includes an anchor wall section (1), a test wall section (2), a reaction wall section (3), and an anchor beam (4) , reaction beam (5), self-balancing beam (6). The anchor wall section (1), the test wall section (2), and the reaction wall section (3) are different areas of the same outsourcing steel plate concrete wall section, and the section wall is 1m thick, 4m long, and 3m high; The anchor wall section (1) is located at the bottom of the structure, 4m long and 1.5m high; the test wall section (2) is located on the upper side of the anchor wall section (1), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com