A kind of sweeping device for water delivery ditch wall in water conservancy project

A water conservancy project and water delivery ditch technology, which is applied in construction, earth mover/excavator, etc., can solve the problems of high labor intensity and low work efficiency of operators, and achieve good cleaning effect, low labor intensity and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

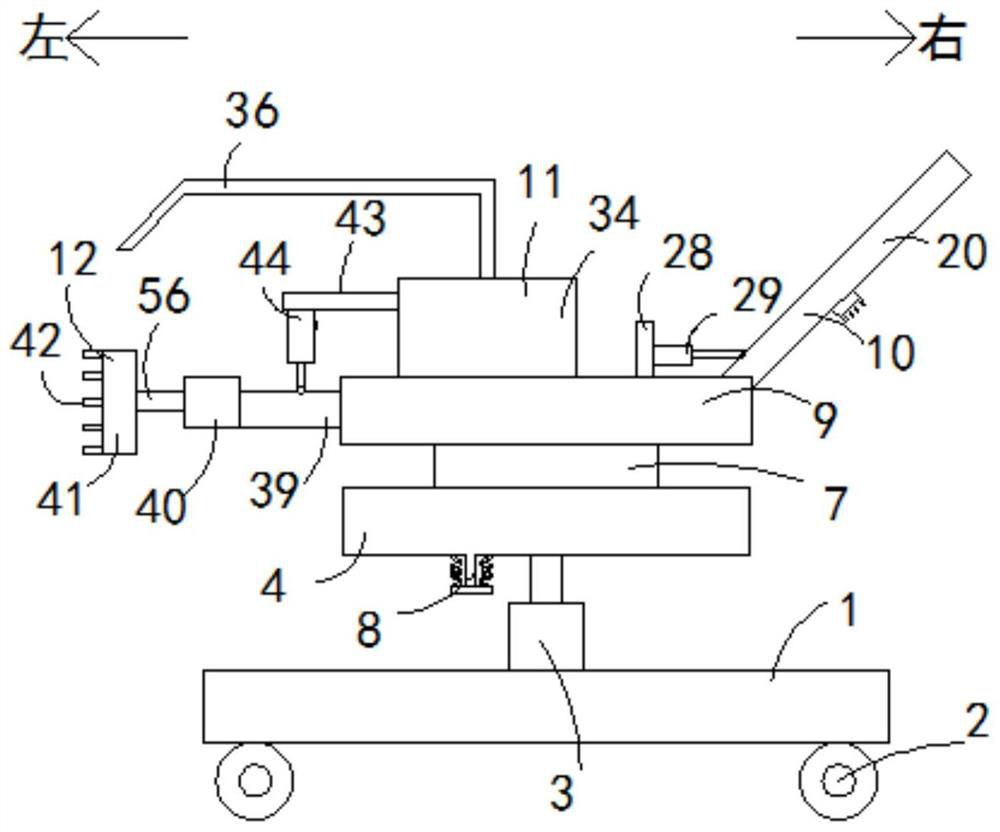

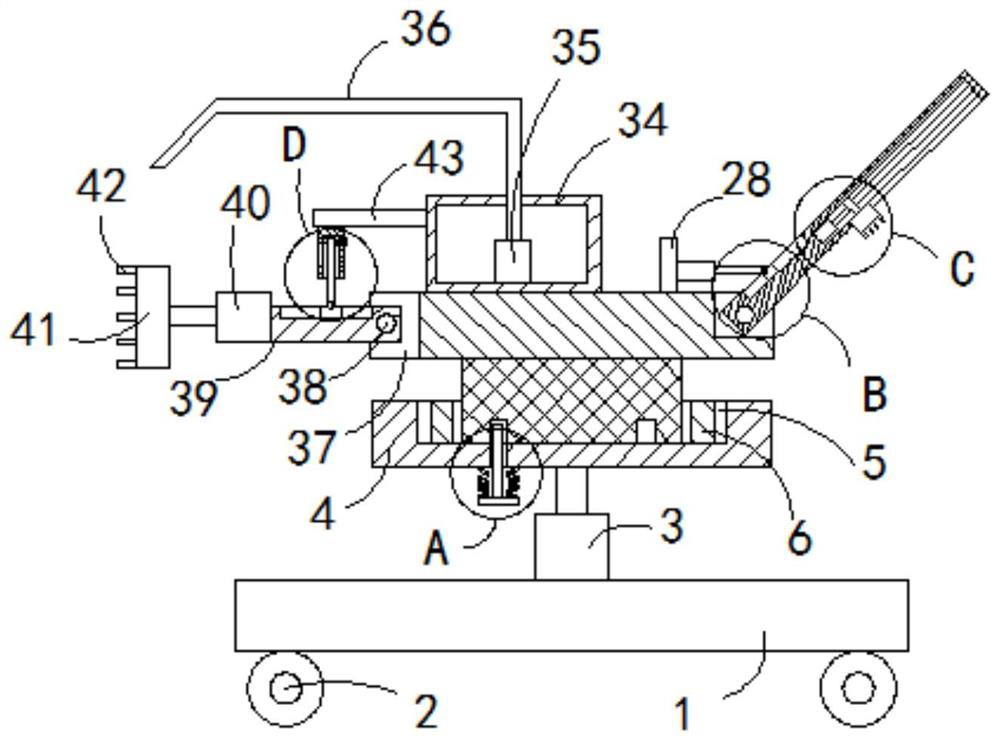

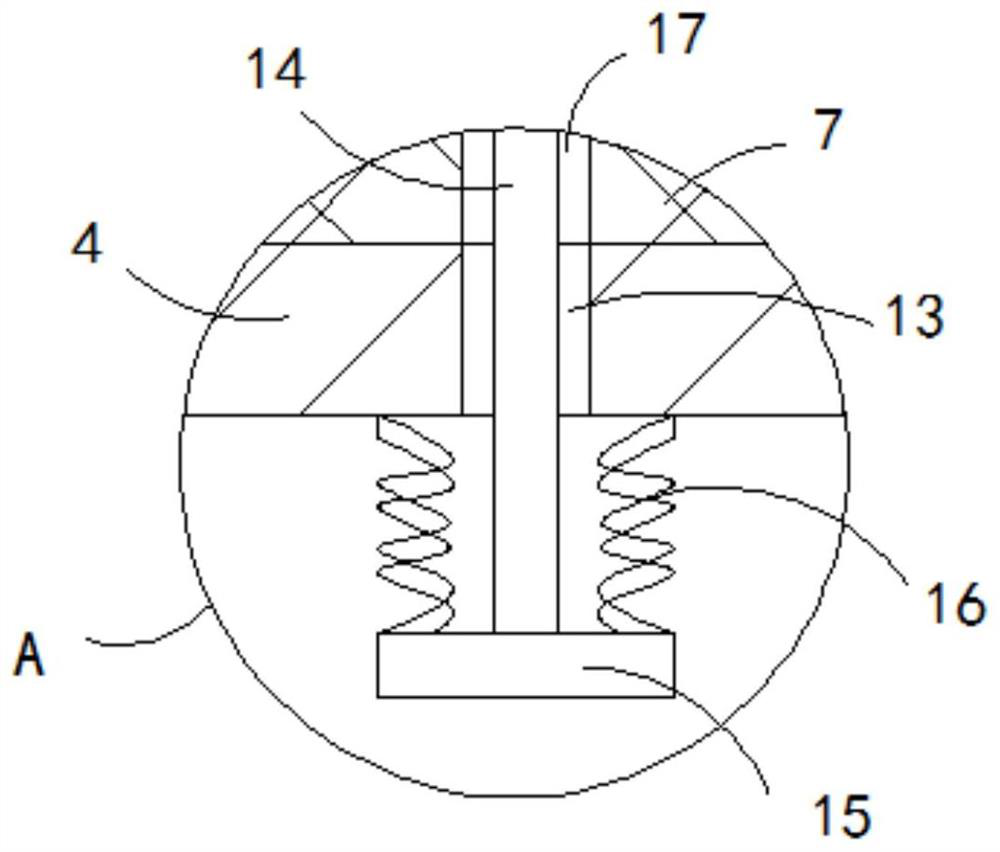

[0026] Such as Figure 1-6 As shown, a water delivery ditch wall scraping device for water conservancy projects includes a base plate 1, a plurality of universal wheels 2 are installed on the lower end of the base plate 1, so as to move the device to a suitable position, and the upper end of the base plate 1 is fixedly connected with The two first electric push rods 3 can adjust the device to a suitable height, so that the operator can use it. The upper ends of the two first electric push rods 3 are fixedly connected with the same horizontal plate 4, and the upper end of the horizontal plate 4 is provided with a second A groove 5, the inner wall of the first groove 5 is fixedly connected with a ball bearing 6, the inner wall of the ball bearing 6 is fixedly connected with a cylinder 7, the cylinder 7 is rotatable, and the horizontal plate 4 is provided with a limit mechanism 8, so that The rotated cylinder 7 is limited, and the upper end of the cylinder 7 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com