Automatic feeding mechanism for oral liquid bottle aluminum caps

An automatic feeding and oral liquid technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of aluminum cover scratching hands, high labor cost, low assembly efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

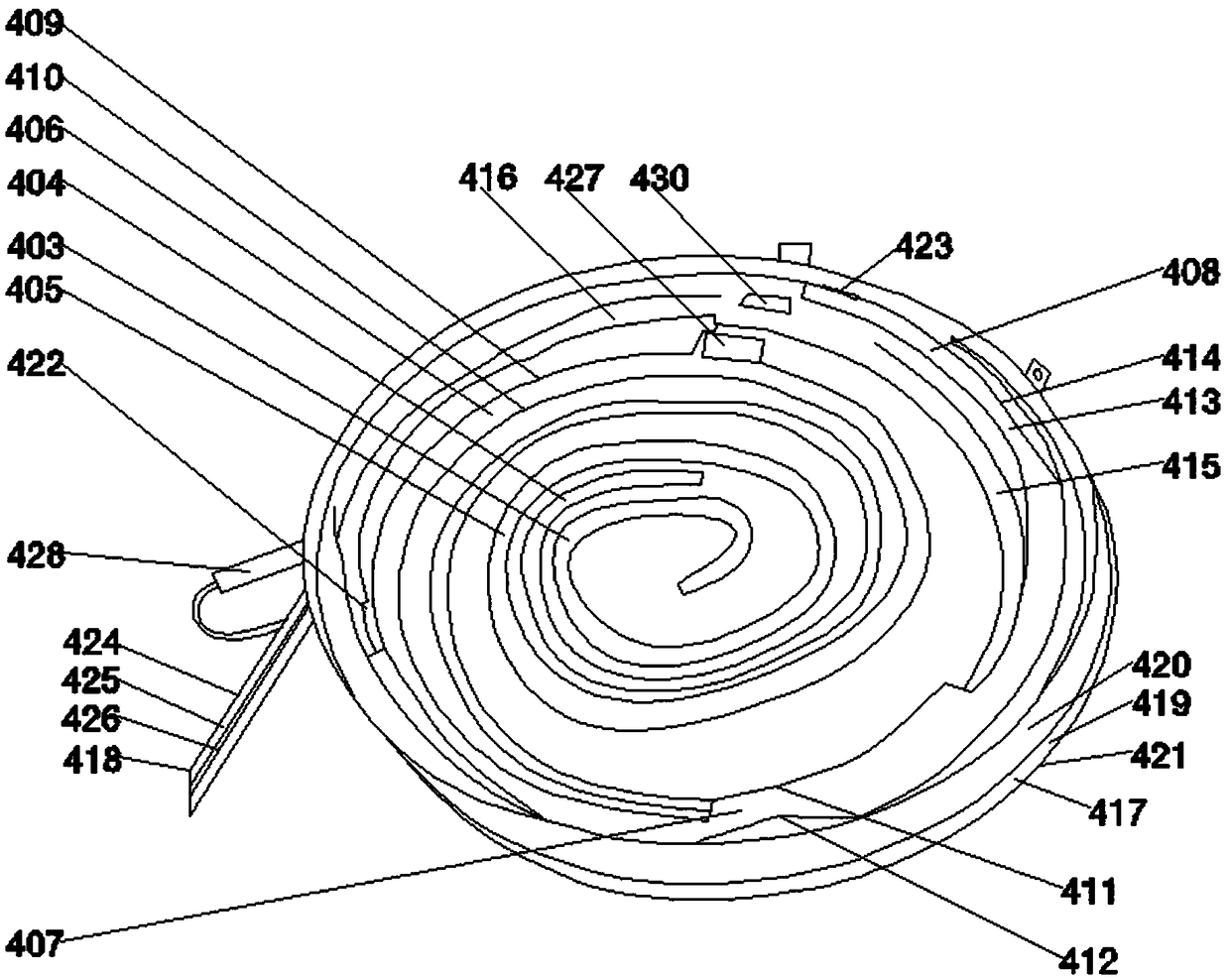

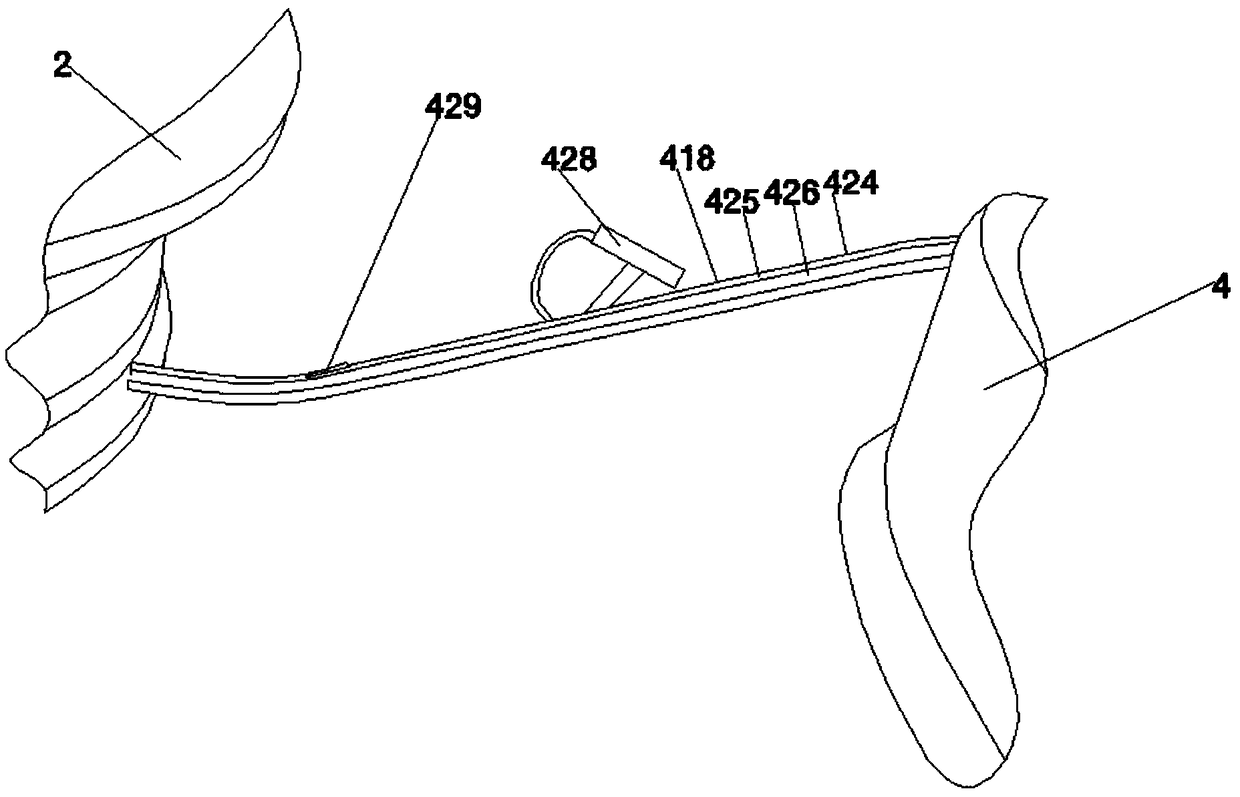

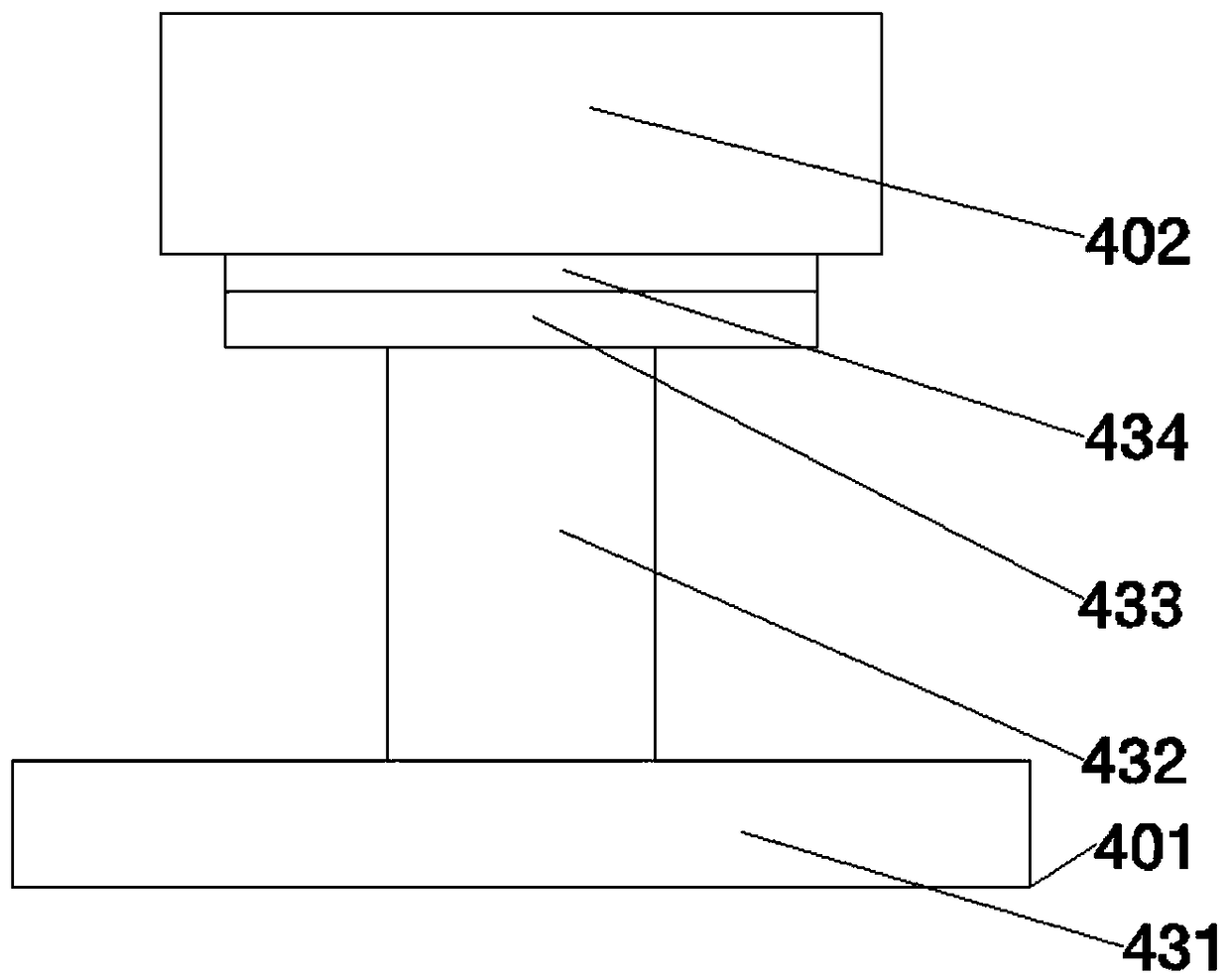

[0036] Such as figure 1 , figure 2 and image 3The automatic feeding mechanism for the aluminum cap in the shown oral liquid bottle cap includes a first vibrating assembly 401 and a first conical feeding tray 402 arranged on the first vibrating assembly, and a second conical feeding tray is arranged side by side on the first vibrating assembly. A spiral conveying track 403 and a second spiral conveying track 404, the first spiral conveying track comprises a first spiral conveying section 405, a second spiral conveying section 406, a first twisting section 407 and a third spiral conveying section 408 connected in sequence, A spiral conveying section and a second spiral conveying section are arranged on the inner wall surface of the first conical feeding tray, and the first torsion section and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com