A kind of fully automatic preparation method of ready-mixed dry-mixed mortar

A dry-mixed mortar and preparation method technology, which is applied in the direction of mixing operation control, chemical instruments and methods, mixing plants, etc., can solve the problems such as the inability to adjust the distribution ratio of mortar components, and the unsatisfactory control effect of mortar humidity, so as to achieve convenient manufacturing and installation , convenient inspection and maintenance, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

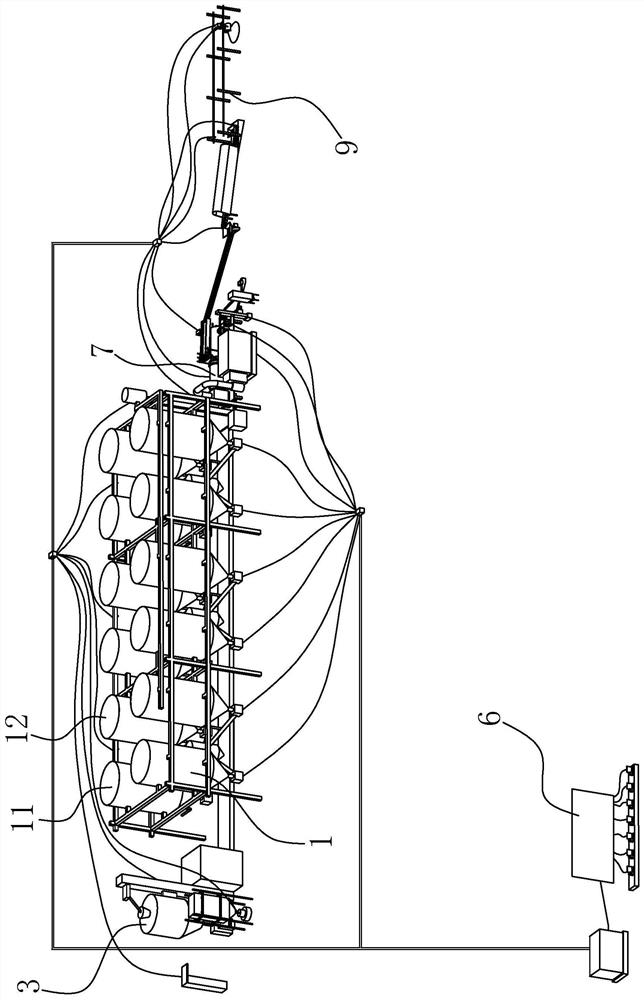

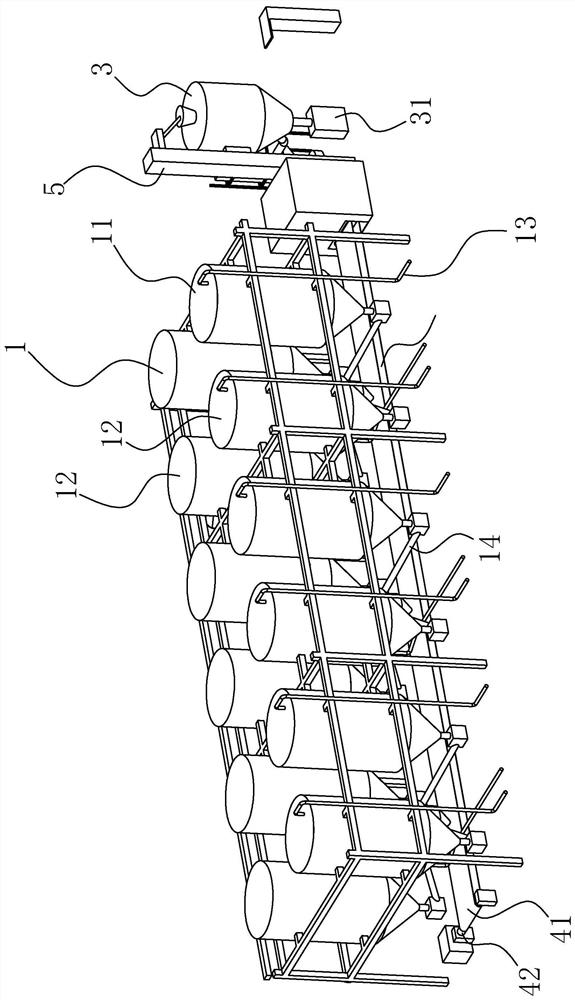

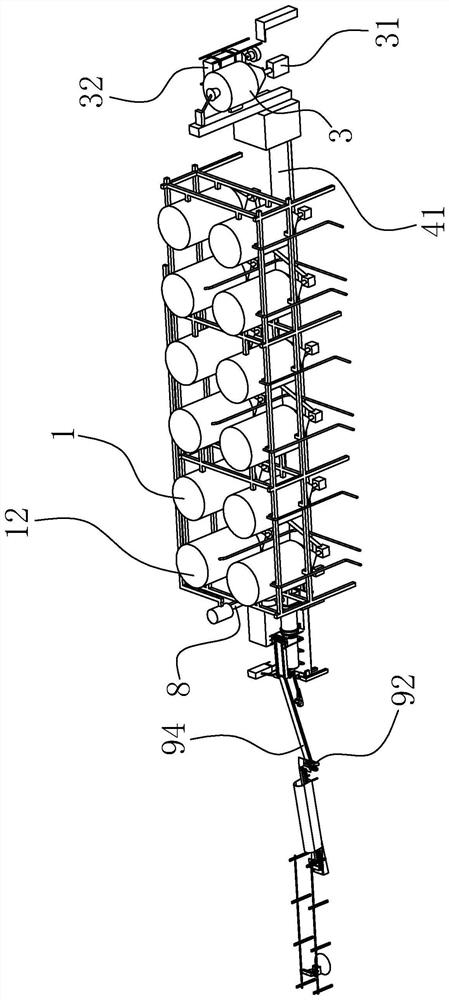

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] Such as Figure 1 to Figure 12 As shown, the fully automatic ready-mixed dry-mixed mortar preparation method of the present embodiment comprises the following steps,

[0038] 1. Transport the raw materials required for the preparation of premixes and store them for later use;

[0039] 2. Transport the sand to the sand drying device for drying;

[0040] 3. The dried sand is transported to the sand particle separator 81 through the lifting device to separate fine sand and coarse sand;

[0041] 4. The separated fine sand and coarse sand are respectively stored in the corresponding sand tank 1;

[0042] 5. The raw materials stored for use except the sand and the dried and separated sand are sealed and transported to the meter 2;

[0043] 6. Meter 2 outputs the mixture according to the set ratio of raw materials;

[0044]7. Promote the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com