Coarse and fine layered, fast and slow combined and active and passive integrated multi-level composite control method for spacecraft

A composite control and spacecraft technology, applied in attitude control, aerospace vehicles, aircraft and other directions, can solve the problem that the load pointing accuracy and stability cannot be further improved, the optical load cannot further improve the imaging quality, and the accuracy cannot achieve flexible vibration. and high-frequency micro-vibration active control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

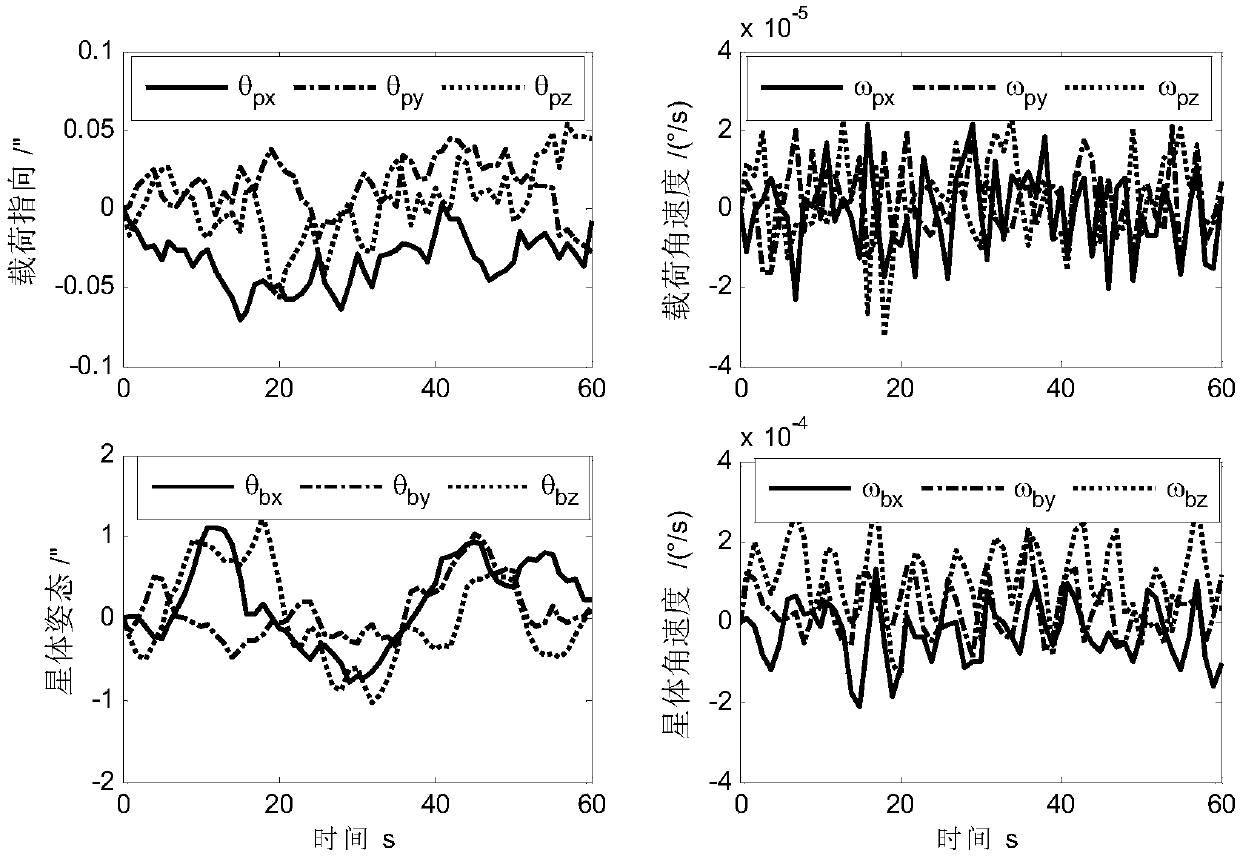

[0064] The present invention adopts figure 1 The process shown in the figure completes a multi-level compound control method of combining coarse and fine layering speed of the spacecraft with the integration of main and passive parts: the specific method is as follows:

[0065] (1) The multi-level composite control system of the spacecraft mainly includes the star platform, the active pointing ultra-static platform, the payload, and the fast mirror. The astral platform is used to support the active pointing ultra-static platform and the load; the active pointing ultra-static platform is installed between the load and the astral platform. The payload is an optical system for high-quality imaging of the target celestial body; the fast mirror is installed inside the payload to adjust the pointing method of the payload's optical axis. The sensors in the spacecraft multi-level compound control system include: star gyroscope, load micrometer sensor, load star sensor, active pointin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com