A fully automatic scissor robot climbing frame

A fully automatic and robotic technology, which is applied to scaffolding supported by housing structures, buildings, housing structures, etc., can solve the problems of poor continuity of frame erection work, difficult to control frame safety, and narrow wellbore space, etc. The effect of preventing the climbing frame from falling, improving construction efficiency and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

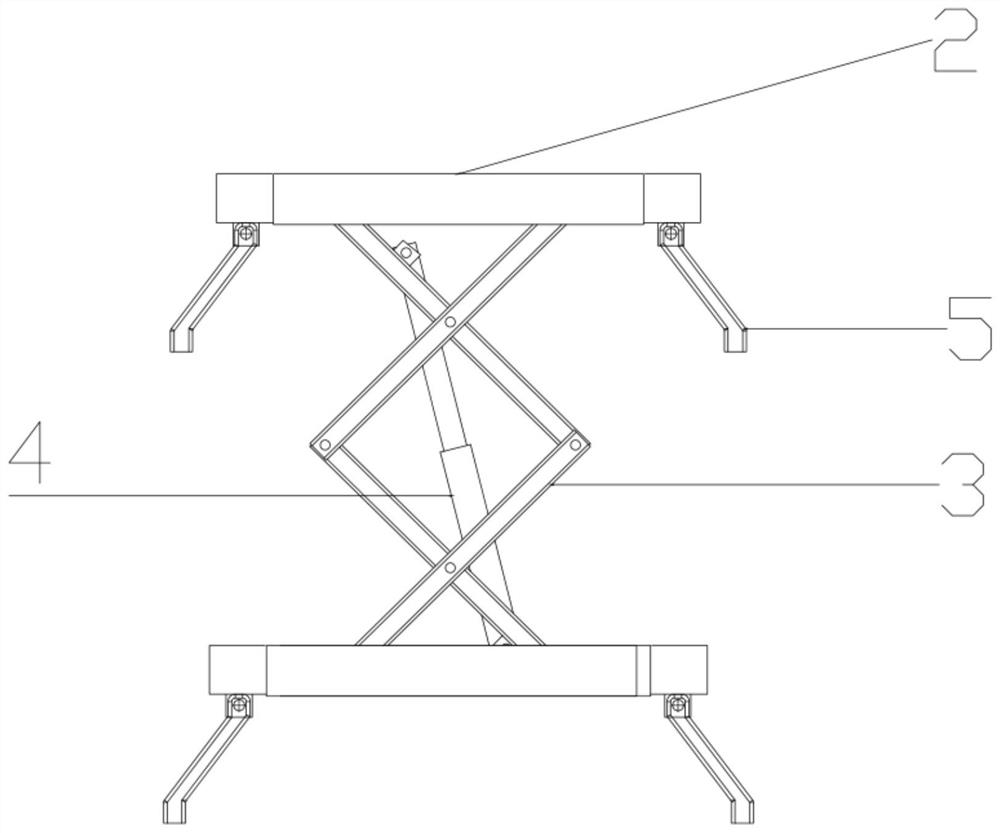

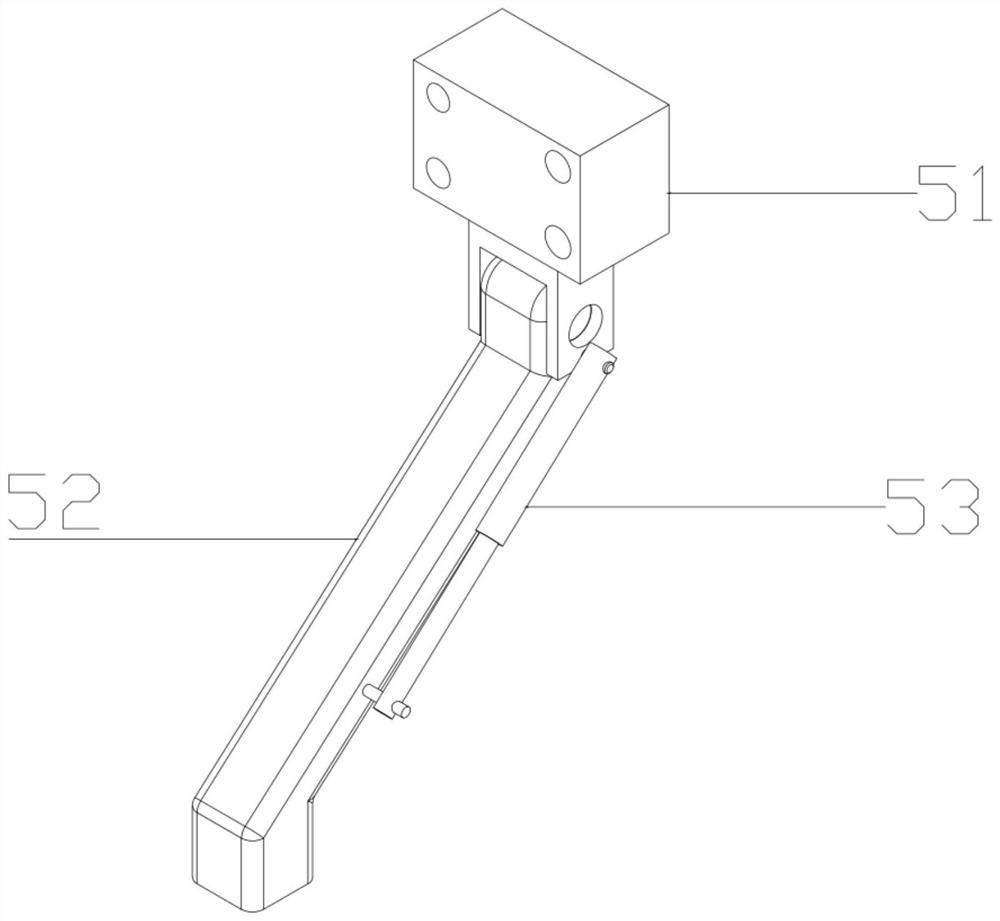

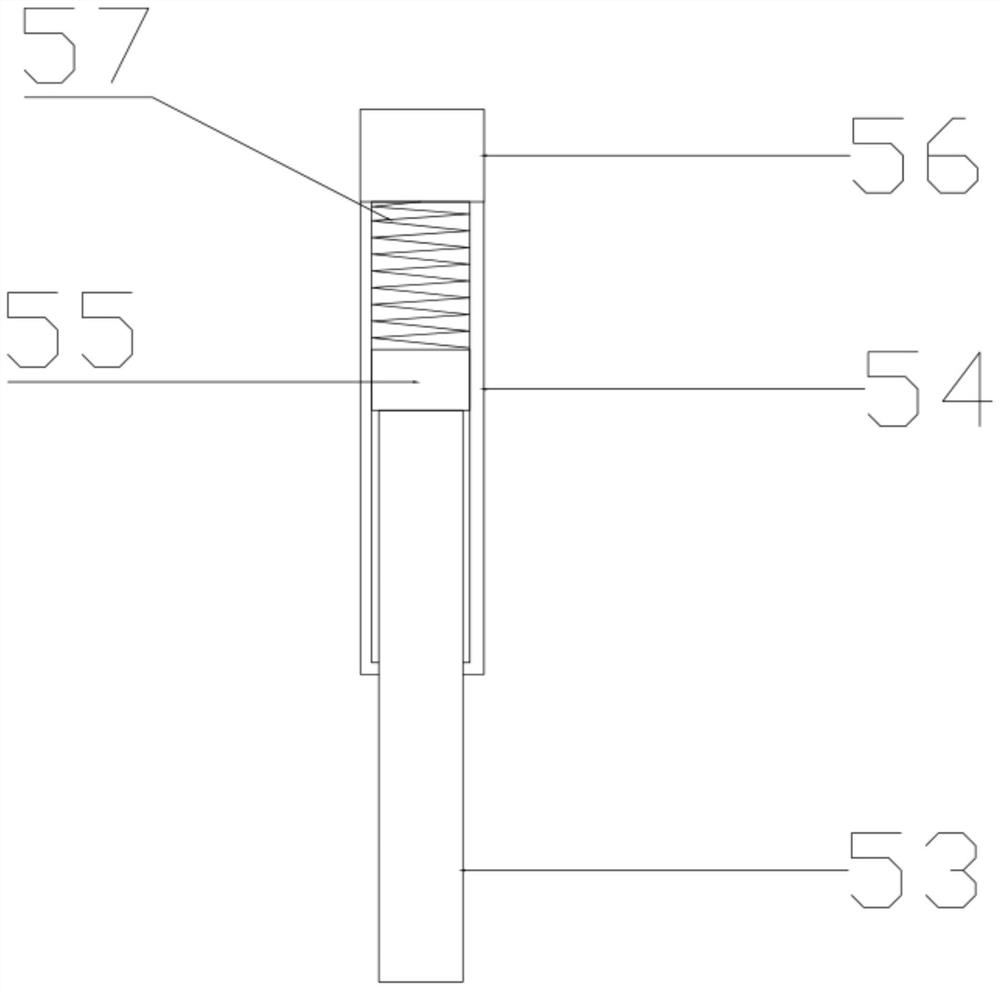

[0029] like figure 1 As shown, the fully automatic scissor robot climbing frame provided by Embodiment 1 of the present invention is used in the inner cylinder of a building, such as in an elevator shaft, where a single elevator shaft is often surrounded by walls or beams. The embodiment of the present invention comprises two vertically distributed climbing platforms 2, a scissor device 3 connected between the up and down adjacent climbing platforms 2, a driving device 4 connected to the scissor assembly in the scissor device 3 and installed on the The mechanical arm 5 on the climbing platform 2. Climbing platform 2 can be used for worker's construction and stacking material. The scissor device 3 has the advantages of stable structure, low failure rate, reliable operation, safety and high efficiency, and simple and convenient maintenance. There are two states of folding, and in the process of opening and contracting, the climbing platform 2 connected with it also moves there...

Embodiment 2

[0032] like Figure 4 As shown, the difference between embodiment two and embodiment one is that it also includes a skid 8 and a guide wheel 9 for guiding. contact; the guide wheel device 9 is installed on the climbing platform 2, and is in contact with the inner wall of the elevator shaft through rolling friction. When installing, it is preferable to install the skid 8 or the guide wheel 9 on the opposite side of the climbing platform 2 at the same time, or install the skid 8 on one side and the guide wheel 9 on the other side, so that the force on the whole climbing frame is evenly distributed around, preventing The climbing frame is tilted.

[0033] Specifically, a fixed seat is provided on the topmost climbing platform 2, and a sliding sleeve is provided on the bottommost climbing platform 2. One end of the sliding skid 8 is fixed on the fixing seat by screws, and the other end is movably connected with the sliding sleeve. Through this setting, the multiple climbing plat...

Embodiment 3

[0035] Compared with the second embodiment, the third embodiment is different in that: the present embodiment is provided with a four-layer climbing platform 2, if only the function of automatic climbing of the climbing frame is needed, a scissor device is set between any group of climbing platforms 2 3; in order to realize the portability and ease of assembly of the climbing frame at the same time, in this embodiment, the climbing platforms 2 on each floor are connected by a scissor device 3, and multiple climbing platforms are provided on the climbing platform 2 for tower crane hoisting. The lifting ring 1 of each climbing platform 2 can realize the minimization of the volume space through the folding function of the scissor device 3, so as to facilitate lifting, assembly and transportation. Specifically, the installation process of the climbing frame provided in this embodiment is as follows: Figure 7 As shown, in the factory, the climbing platform 2, the scissor device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com