Device for manufacturing knife switch static contact and manufacturing method of knife switch static contact

A technology of static contact and knife switch, which is applied to electrical components, electrical switches, circuits, etc., can solve the problems of high labor and time cost, occupying bus power outage time, increasing bus power outage time, etc., so as to achieve short assembly time and reduce Outage time, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

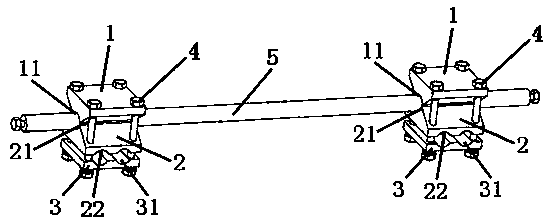

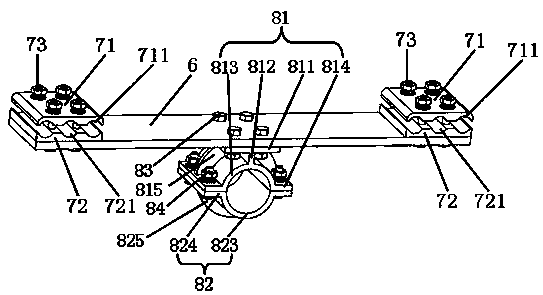

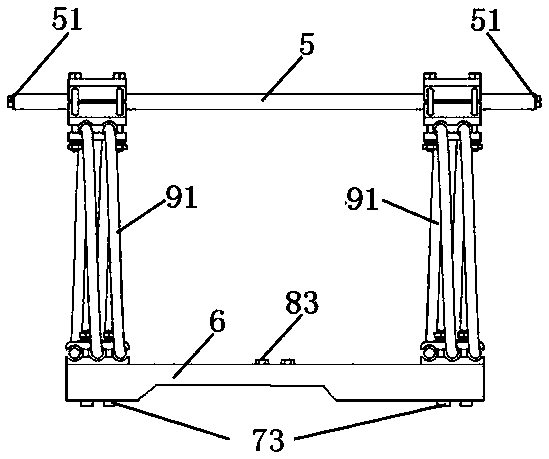

[0034] see Figure 1 to Figure 3 , and see Figure 4 to Figure 7 , a knife switch static contact, consisting of two identical upper fixing plates 1, two identical lower fixing plates 2, two identical second twisted wire clamps 3, eight sets of identical first fixing elements 4, conductive Rod 5, fixed pressing plate 6, two identical third strand clamps 71, two identical fourth strand clamps 72, eight sets of identical second fixing elements 73, first busbar fixing part 81, second busbar fixing Part 82, four identical third fixing elements 83, four identical fourth fixing elements 84, and two conductive twisted wires 91; it is characterized in that:

[0035] The upper surface of the upper fixed plate 1 is a plane, and the lower surface of the upper fixed plate 1 has a first conductive rod groove 11. The first conductive rod groove is semi-cylindrical and is the upper surface of the upper fixed plate 1. Recessed, the front and rear surfaces of the upper fixing plate 1 have a t...

Embodiment 2

[0060] See Figure 8 , and see Figure 1 to Figure 7 , a device for making the static contact of the knife switch, which is basically the same as the implementation example 1, except that the upper and lower adjacent adjustment holes 411 are connected through the connecting groove 412. In this case, The conductive rod fixing member 51 can be moved between the connecting grooves 412, so that the height of the conductive rod can be adjusted more quickly and conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com