A Process Compatible Method for Monolithically Integrated Inertial Devices

A technology that integrates inertia and devices. It is used in metal material coating processes, processes for producing decorative surface effects, decorative arts, etc. It can solve the problems of large difference in structural thickness and damage of off-plane moving devices and in-plane moving devices. , to achieve the effect of reducing process deviation and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

[0019] See attached Figures 1 to 8 As shown, the above-mentioned single-chip integrated inertial device process compatibility method can adopt a process, which includes the following steps:

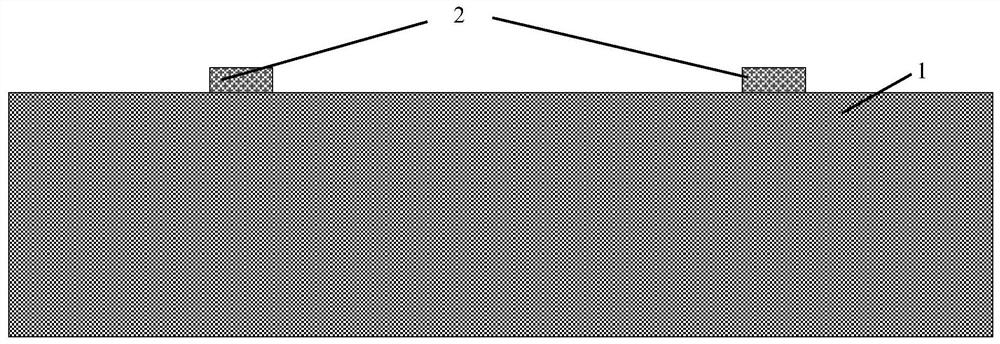

[0020] (1) grow on (111) silicon wafer 1 Silicon oxide, after photolithography, etched by RIE to form the bonding area mask 2, such as figure 1 shown;

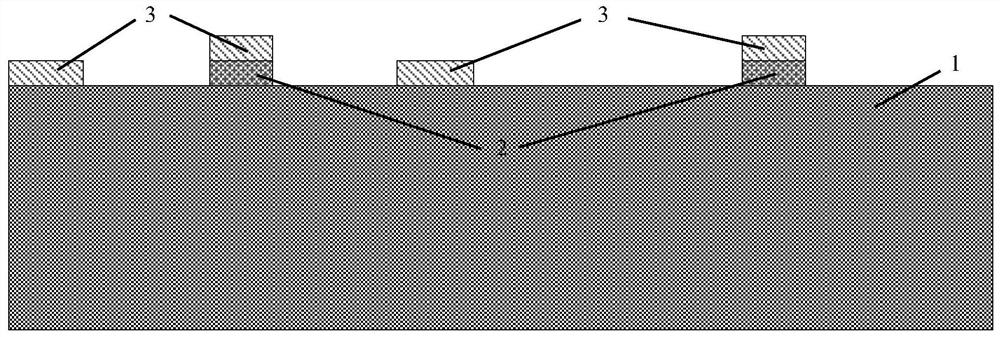

[0021] (2) Use the photoresist as a mask to carry out the second photolithography to form the mask pattern required for the steps of the back cavity with different heights. At this time, a silicon oxide mask 2 and a photoresist mask 3 are formed on the silicon wafer Composed of composite masks, such as figure 2 shown;

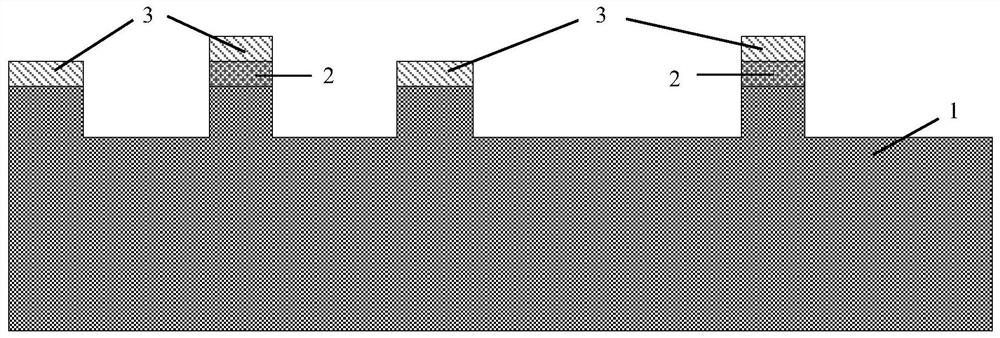

[0022] (3) Use the photoresist as a mask to perform DRIE deep etching with a depth of about 15um, such as image 3 shown;

[0023] (4) R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com