A method for enhancing lift and realizing vertical take-off and landing by mounting a drive mechanism under a panel wing

A technology of vertical take-off and landing and driving mechanism, which is applied in the aviation field, and can solve problems such as unsmooth and natural switching, divergence of chord-wise blowing airflow, and low flight efficiency, so as to achieve natural mode switching, avoid machine damage, and scientific and reasonable movement path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

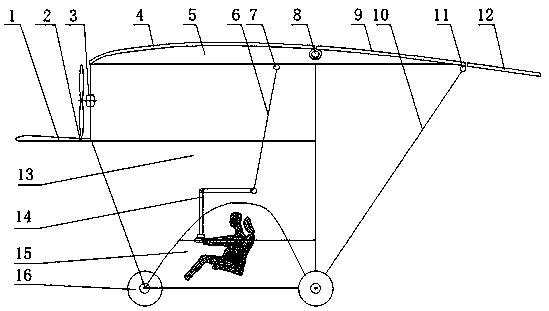

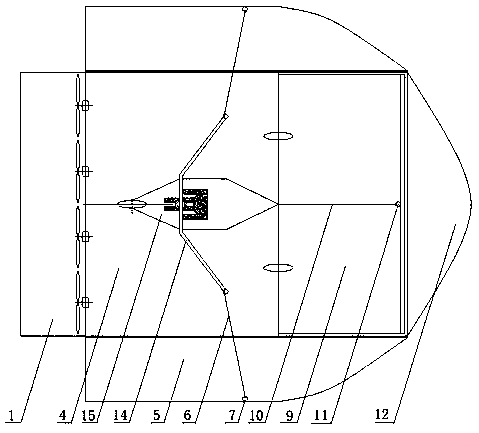

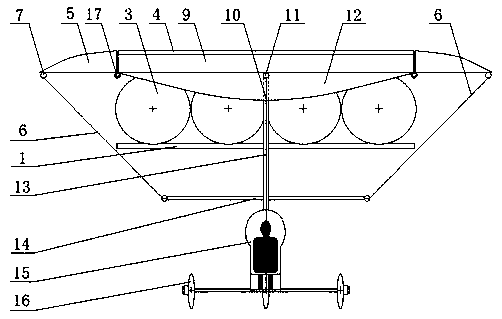

[0038] Embodiment 1: as Figure 1-18 As shown, this method of installing a driving mechanism under the wing to enhance lift and realize vertical take-off and landing, uses the wing as the aircraft wing, and sets the driving device at the front lower part of the leading edge of the wing, through which the driving device moves toward the wing along the chord direction. The lower part blows high-speed airflow, and the air inlet of the drive device forms a negative pressure area above the wing, and the air outlet forms a positive pressure area below the wing, so that the negative pressure area above the wing and the positive pressure area below form a pressure difference At the same time, set the plate wing as a combined type. When taking off and landing vertically, the left and right sides and the rear part of the combined plate wing will change the airflow direction of the propeller slipstream from the horizontal direction to the vertical downward direction, so as to increase the...

Embodiment 2

[0047] Embodiment 2: as Figure 1-18 As shown, this method of installing a driving mechanism under the wing to enhance lift and realize vertical take-off and landing, uses the wing as the aircraft wing, and sets the driving device at the front lower part of the leading edge of the wing, through which the driving device moves toward the wing along the chord direction. The lower part blows high-speed airflow, and the air inlet of the driving device forms a negative pressure area above the wing, and the air jet forms a positive pressure area below the wing, using the pressure formed by the negative pressure area above the wing and the positive pressure area below. At the same time, set the plate wing as a combined type. When taking off and landing vertically, the left and right sides and the rear part of the combined plate wing will reverse the airflow direction of the propeller slipstream from the horizontal direction to the vertical downward direction to increase the lift. The ...

Embodiment 3

[0057] Embodiment 3: As shown in Figure 1-18, this method of installing a driving mechanism under the wing to enhance the lift and realize vertical take-off and landing, adopts the aircraft with the wing as the wing, and sets the driving device at the front lower part of the leading edge of the wing , through the driving device blowing high-speed airflow to the lower part of the wing along the chord direction, the air inlet of the driving device forms a negative pressure area above the wing, and the air outlet forms a positive pressure area under the wing, using the negative pressure area above the wing and the pressure difference lift formed by the positive pressure area below; at the same time, the plate wing is set as a combined type. When taking off and landing vertically, the left and right sides of the combined plate wing and the rear part reverse the airflow direction of the propeller slipstream from the horizontal direction. In order to vertically downward, it plays the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com