Manufacturing method of UAV non-equal-diameter closed square tubular carbon fiber beam structural parts

A manufacturing method and non-equal-diameter technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of limited molding applications, achieve the effects of simplified molding process, stable dimensions, and improved demoulding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0056] The first step is tooling design.

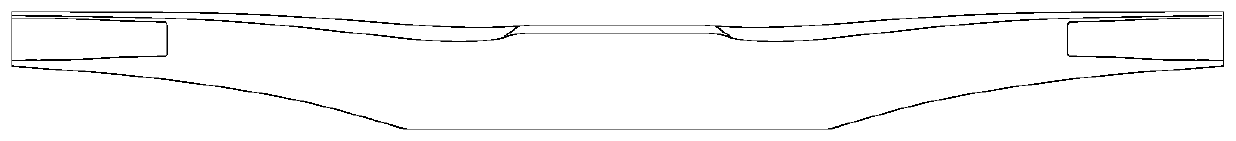

[0057] refer to figure 1 , the product in this example is a typical non-equal diameter closed square tubular carbon fiber beam structure special-shaped part, not only the two ends are small, the middle part is large, but also the two ends are distributed with symmetrical indented grooves, which can be plugged with other carbon fiber composite material connectors , fixed, and easy to load transfer.

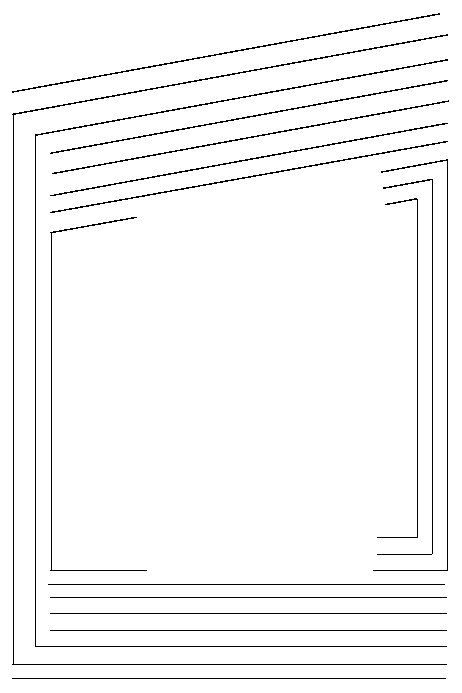

[0058] According to the three-dimensional digital model of the product, CATIA software is used for tooling design, and mold processing is carried out according to the digital model to obtain the overall airbag forming mold.

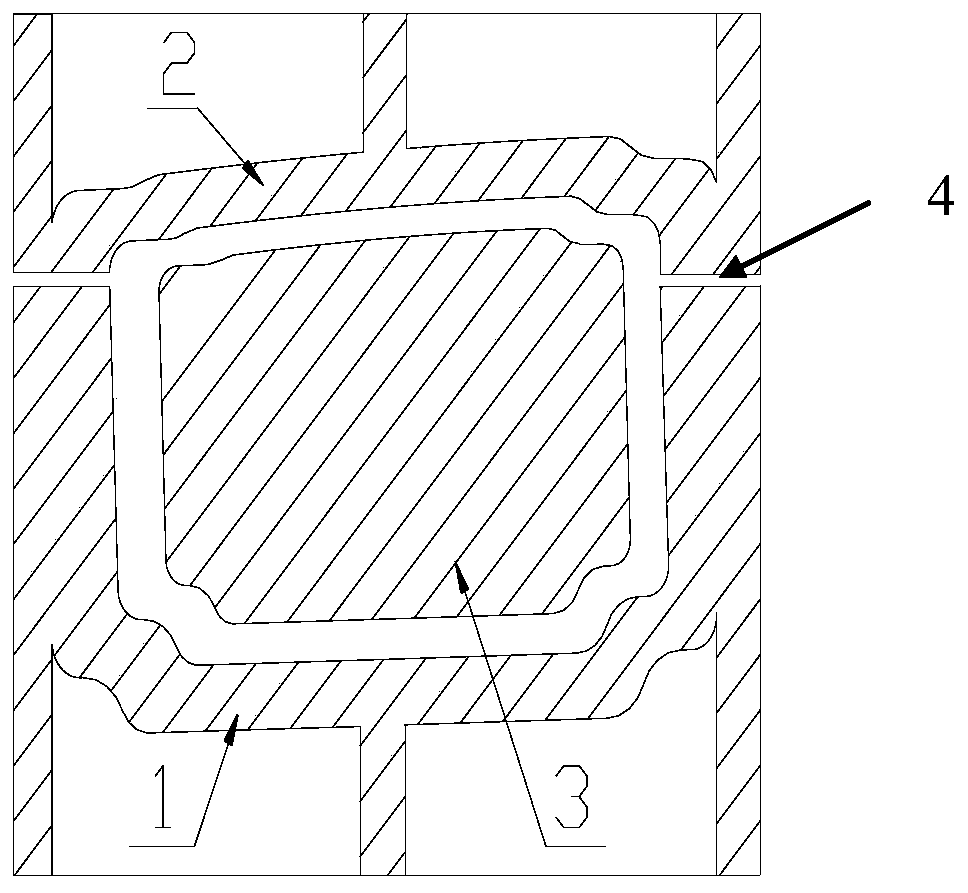

[0059] refer to image 3 , the overall airbag forming mold is mainly composed of the lower female mold 1 and the upper female mold 2, the lower female mold 1 is the main forming mold, and the tooling mold is divided into blocks along the process separation surface; the upper female mold 2 is used in conjunction with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com