Quantitative analysis method of temperature distribution of gis equipment shell

A technology of quantitative analysis and shell temperature, applied in the directions of temperature distribution map, radiation pyrometry, measuring device, etc., can solve the problems of difficult heat dissipation, gas decomposition, abnormal thermal image of equipment, etc., and achieve the effect of improving the accuracy of on-site detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

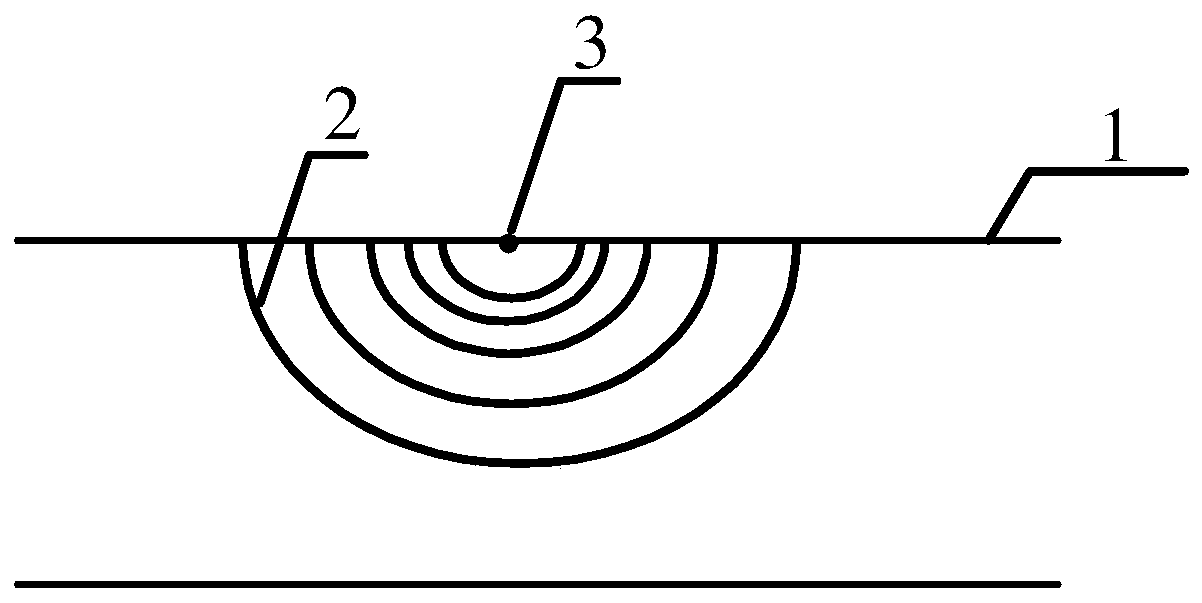

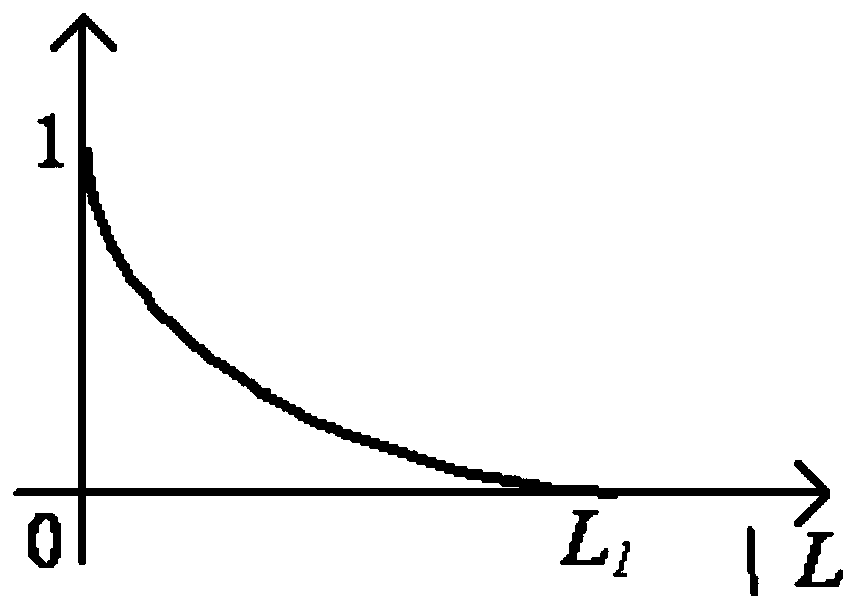

[0016] The invention relates to a quantitative analysis method for the temperature distribution of the shell of GIS equipment. Specifically, an infrared imager is used to measure the surface temperature of the shell of the GIS equipment, and the temperature distribution map obtained is extracted from the temperature distribution map, and the isotherm is drawn, and then obtained. Temperature gradient curve, normalize the temperature gradient curve, calculate its equivalent area percentage, analyze the shell temperature of the GIS equipment according to the equivalent area percentage, and then judge whether the heat source comes from the inside of the GIS or the shell surface.

[0017] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described according to the accompanying drawings.

[0018] Step (1): Measure the temperature distribution of the shell of the tested GIS equipment to obtain its infrared therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com