Dredging rubber pipe capable of being pressed flat

A rubber tube and rubber technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as troubles, and achieve the effects of ensuring stability, reasonable structural design, and guaranteed interception effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

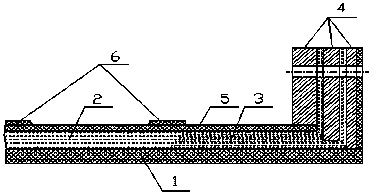

[0011] Depend on figure 1 It is known that a crushable dredging rubber pipe includes a pipe body and a connecting rubber flange. The innermost layer of the pipe body is a high-strength, high-wear-resistant rubber layer, that is, the medium-resistant layer 1, and a high-strength skeleton reinforcement layer 2 is laid outside the medium-resistant layer 1. This reinforcement layer consists of several layers of high-strength cords, and the cords are pressed by Winding at a certain angle, and wrapping tightly on the metal part 4 in the rubber flange in the way of turning over the bag. Additional cord layers 3 are added outside the skeleton reinforcing layer 2 and at both ends of the pipe body. The cords are wound at a certain angle and at a certain length, and are tightly wrapped on the metal part 4 in the rubber flange in a turned-over manner. In order to improve the pressure resistance and tensile strength of the hose. Outside the cord layer is an outer rubber layer 5, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com